7

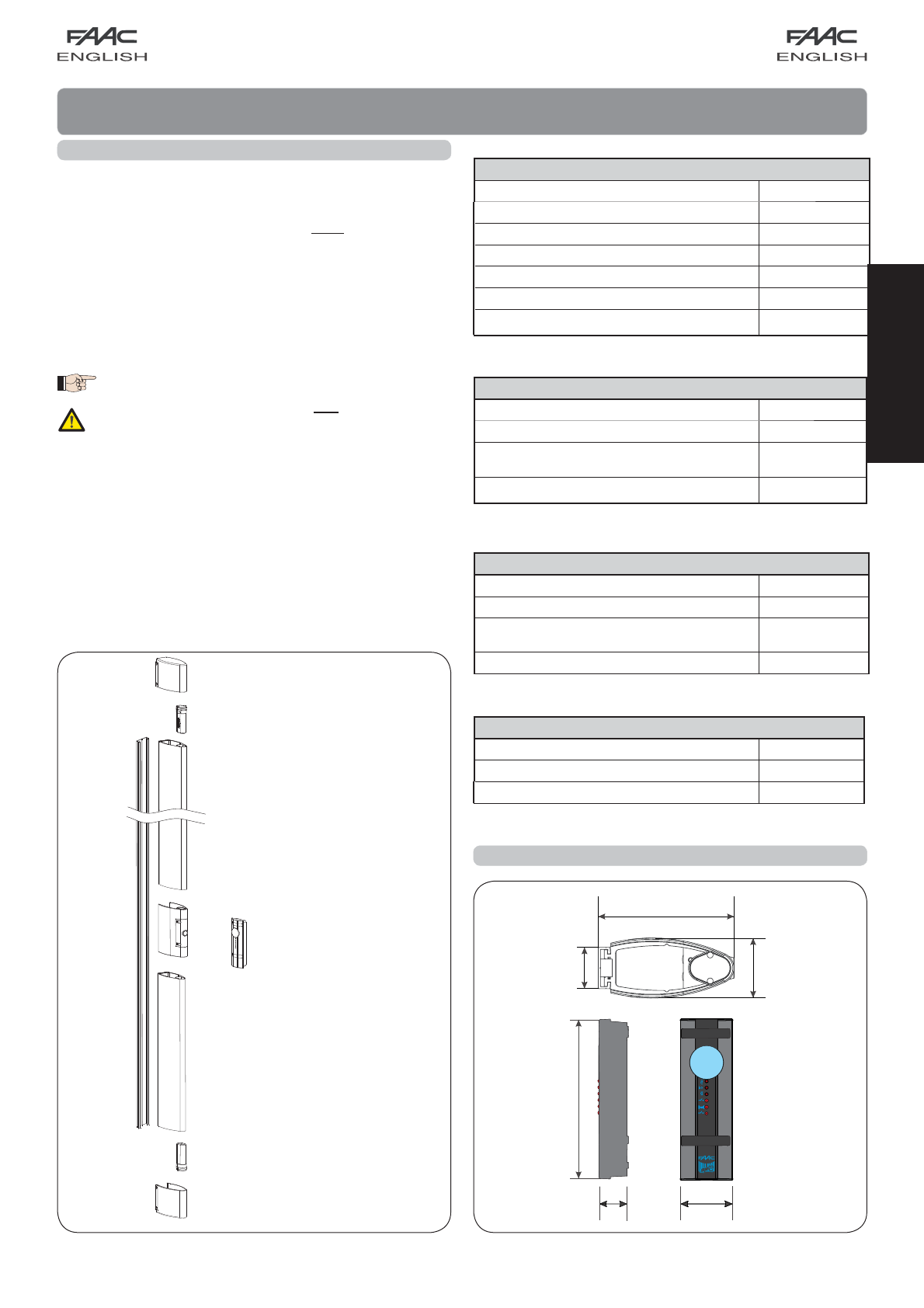

45 mm.

135 mm.

L2

L1

TX1

TX2

ENGLISH

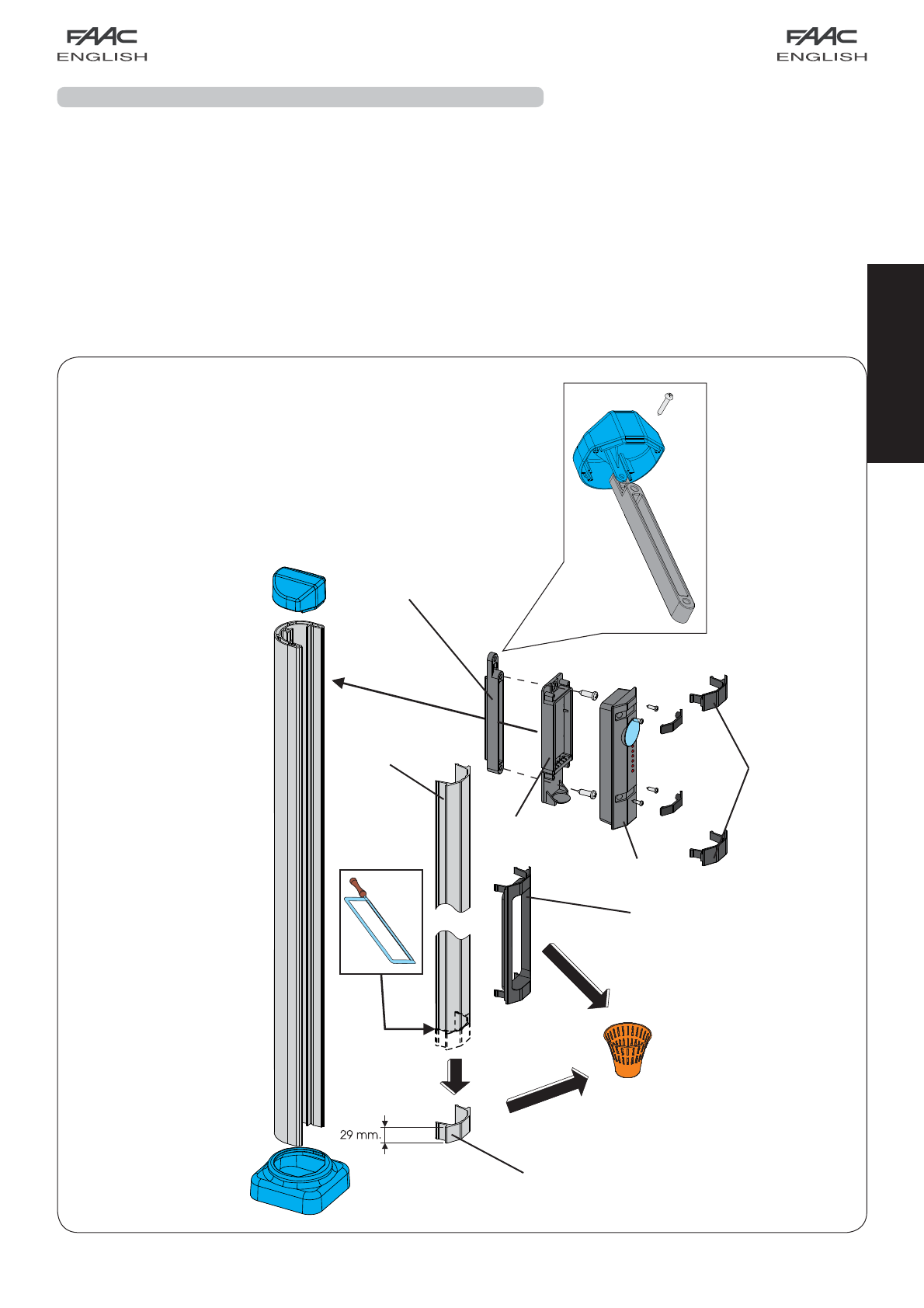

5.3.2 Installing the rubber profiles and the

receiver-transmitter

Fit the batteries (supplied standard) in the top and bottom

transmitters, observing correct polarity as indicated on the

plastic container (TX1 and TX2 Fig. 7).

• Fit the transmitters on the ends of the rubber profiles, observing the

direction indicated in Fig. 7, with the lens on the front detection

border of the edge.

• Fit the bottom rubber profile, sliding it downward along the support

profile, and taking it in contact against the lower support

spacer.

• Remove the front panel of the receiver-transmitter (ref.

Fig. 7B).

Place thebatteries (suppliedstandard) in thereceiver-transmitter,

respecting polarity (Fig. 7A).

• Reinstall the front panel (ref. a Fig. 7B), fastening all the sup-

plied

screws, and, when you install the front panel, make sure that the

lens on the front panel flashes briefly to confirm correct installation.

Fig. 8

• Fit the receiver-transmitter so that the logo is not overturned, sli-

ding it downward along the support profile, until the rigid coupling

is fully inserted in the rubber profile.

Check if the rubber profile and the receiver-transmitter are in

contact with each other.

• Fit the top rubber profile, sliding it downward along the support

profile, making sure that the rigid coupling is fully inserted in the

rubber profile.

Check if the rubber profile and the receiver-transmitter are in

contact with each other.

• Secure the support spacer in the top hole which had been left

free.

5.3.3 Installing the closing caps

Fit the closing caps, checking if they are in contact with the rubber

profiles, and secure them with the self-tapping screws (supplied

standard) in the pre-drilled holes.

Fig. 9

Position the fixed receiver so that the lens on the front panel (Fig. 8

ref. ) is at a height from 50 to 55 cm off the ground. (HT see Fig. 5).

• Separate the bottom (Fig. 8 ref. ) from the front panel (Fig.8

ref. ).

• Mark, for drilling the holes, the two screw securing points (Fig. 8

ref ) - screws not supplied.

• Using adequate screws and expansion plugs, secure the bottom

of the receiver (Fig. 8 ref. ).

•To route the cables, use the facility in the lower part of the

receiver.

• Make the electrical connections as shown in Chap. 6, using the

rubber cable gripper (Fig.8 ref ).

• Assemble the front cover (Fig. 8 ref. ) to the bottom (Fig. 8 ref.

), using the supplied screws (Fig. 8 ref. ), supplied standard.

• Finish installing the receiver, by fitting the rubber protective de-

vices (Fig. 8 ref. ) on the screws.

Fig. 7BFig. 7A

5.3.4 Installing the fixed receiver

ATTENTION before installing the fixed receiver, take a note of

the serial number, on the data-plate on the rear, as indicated

in Chap.8 FINAL OPERATIONS.

Fig. 7