CONTENTS

FOREWORD ..................................................................................................... 5

SCOPE OF THIS MANUAL ................................................................................................ 5

GENERAL INFORMATION ............................................................................... 5

LIMITS OF USE – SAFETY NORMS ................................................................................. 5

GENERAL SAFETY REGULATIONS ................................................................................. 5

MANUFACTURER’S WARRANTY AND LIABILITY ........................................................... 6

PLATES – CONFORMITY MARKS .................................................................................... 6

ENVIRONMENTAL CONDITIONS OF USE ....................................................................... 6

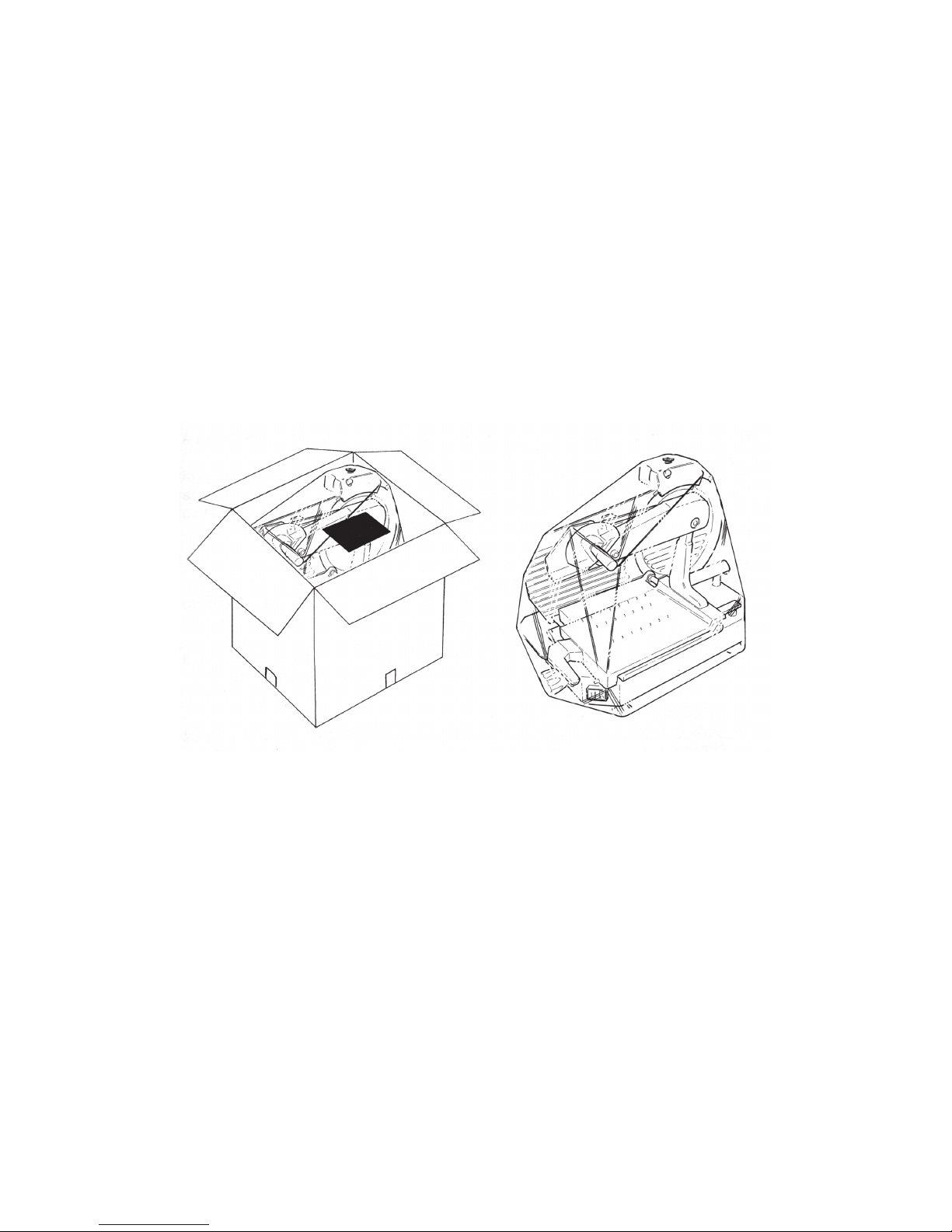

PACKING ......................................................................................................... 7

OPENING THE BOX .......................................................................................................... 7

TECHNICAL DESCRIPTION AND PROPOSED .................................................

CONDITIONS OF USE

8

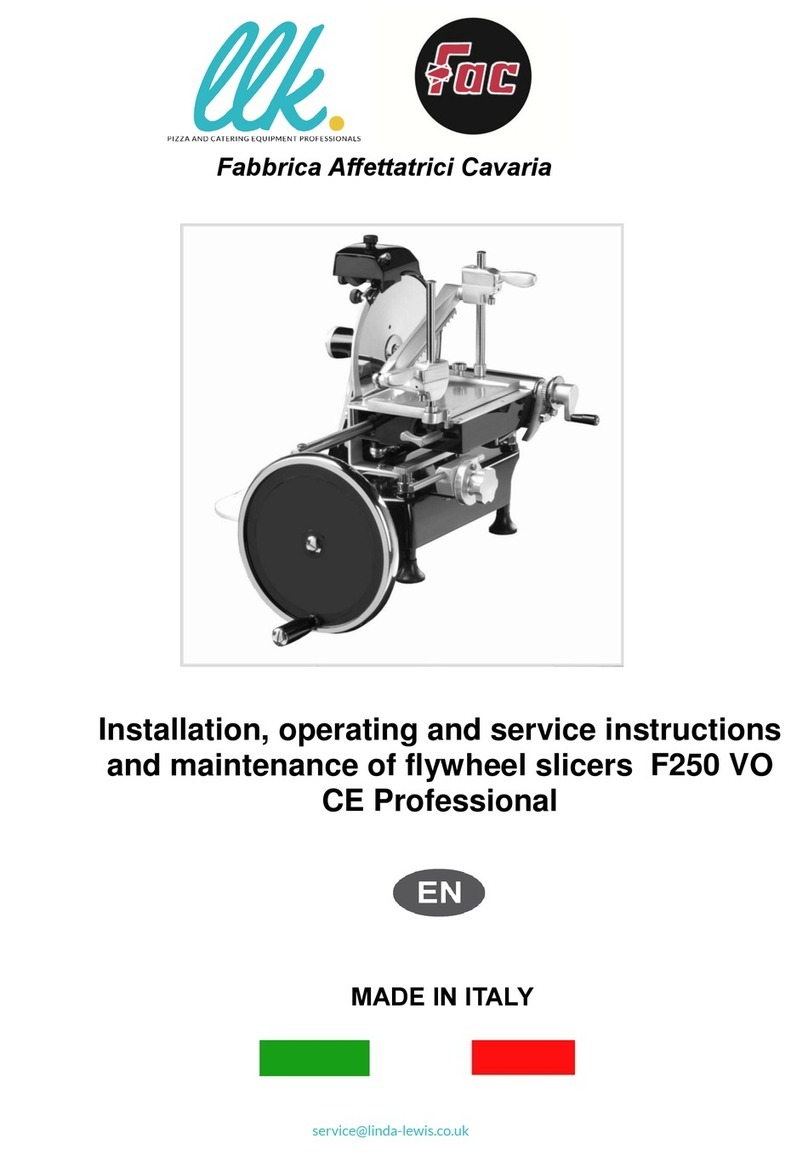

GENERAL DESCRIPTION ................................................................................................. 8

MECHANICAL AND ELECTRICAL SAFETY DEVICES ..................................................... 8

WARNING: RESIDUAL RISKS ........................................................................................... 8

DIMENSIONS AND MAIN TECHNICAL DATA ................................................................... 9

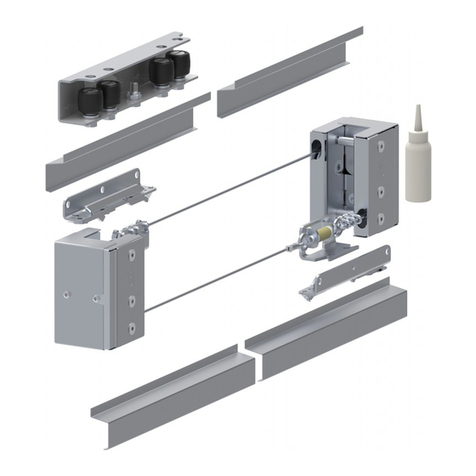

SUPPLIED LITERATURE AND ACCESSORIES ................................................................ 10

PRODUCTS THAT CAN BE SLICED ................................................................................. 10

PRODUCTS THAT MUST NOT BE SLICED ...................................................................... 10

MAIN COMPONENTS ........................................................................................................ 11

MACHINE COMMISSIONING AND FUNCTION TESTS .................................... 12

INSTALLING THE MACHINE ............................................................................................. 12

ELECTRICAL CONNECTION ............................................................................................ 12

COMMANDS ...................................................................................................................... 13

FUNCTIONING TEST AND BLADE ROTATION DIRECTION ............................................ 14

USING THE MACHINE .................................................................................... 15

LOADING THE PRODUCT ON THE TRAY AND SLICING (MOD. TSV) ............................ 15

LOADING THE PRODUCT ON THE TRAY AND SLICING (MOD. TCV) ........................... 18

CLEANING THE SLICER ................................................................................. 21

GENERAL .......................................................................................................................... 21

DISASSEMBLING THE MACHINE FOR CLEANING ......................................................... 21

REASSEMBLING THE MACHINE ...................................................................................... 27

MAINTENANCE ............................................................................................... 28

GENERAL ........................................................................................................................... 28

BLADE SHARPENING ....................................................................................................... 28

SHARPENING .................................................................................................................... 29

LUBRICATION .................................................................................................................... 32

ADJUSTING THE MOTOR BELT TENSION ...................................................................... 32

TROUBLESHOOTING AND REMEDIES ........................................................... 35

DISMANTLING THE SLICER ........................................................................... 36

ANNEXES ........................................................................................................ 37

ELECTRICAL DIAGRAM 97 FA .......................................................................................... 37

THREE-PHASE ELECTRICAL DIAGRAM 1893 (all versions) ........................................... 38

EXPLODED DRAWINGS ................................................................................................... 39

DECLARATION OF CONFORMITY ................................................................... 49

4/50