403250-300 en ma 2017 6

EN

Use of the machine requires great

concentration, PAY ATTENTION AT

ALL TIMES!

• Do not wear loose-tting clothes particularly

with open sleeves; where necessary use

suitable headgear to cover hair.

• When slicing, do not allow anyone to

approach the slicer, especially the blade.

•Do not remove, cover or alter the rating

plates fitted to the machine body and

ensure their prompt replacement in case

of damage.

Do not remove safety devices and

do not alter or remove mechanical

guards.

•Only approved product types should be

sliced, do not attempt to slice products that

are specically excluded (see clause 1.4).

•Ensure that the product holder, receiving

tray, surrounding areas and oor are kept

clean and dry at all times.

•Do not use the slicer as a supporting

surface or lay any object on it that is

extraneous to normal slicing operations.

•Stop the machine immediately and

request the assistance of authorised

technical support staff in the event

of malfunction, suspected breakage,

improper movements, strange noises, etc.

Always use cut and tear-resistant

gloves when performing cleaning and

maintenance.

1.3 - USER WARNINGS

•Check the slicer’s mechanical integrity

prior to every use.

Components should show no signs of

damage or cracks.

If this is not the case, DO NOT use the

slicer and take it to an authorised service

centre so that the necessary checks can

be performed.

The slicer is not designed for use

by people (including children)

with physical, sensory or mental

difficulties unless supervised or

trained by persons responsible for

their safety.

Children and young people should be

supervised so that they do not play

with the slicer.

The blade is very sharp and should

be handled with extreme care.

Do not damage the blade by cutting hard

objects such as bones.

If the dimensions of the food to be

sliced exceeds those specied under

“Effective slice” in the table on page

3, reduce the size in order to work in

safety.

Safe use requires compliance with the

following warnings:

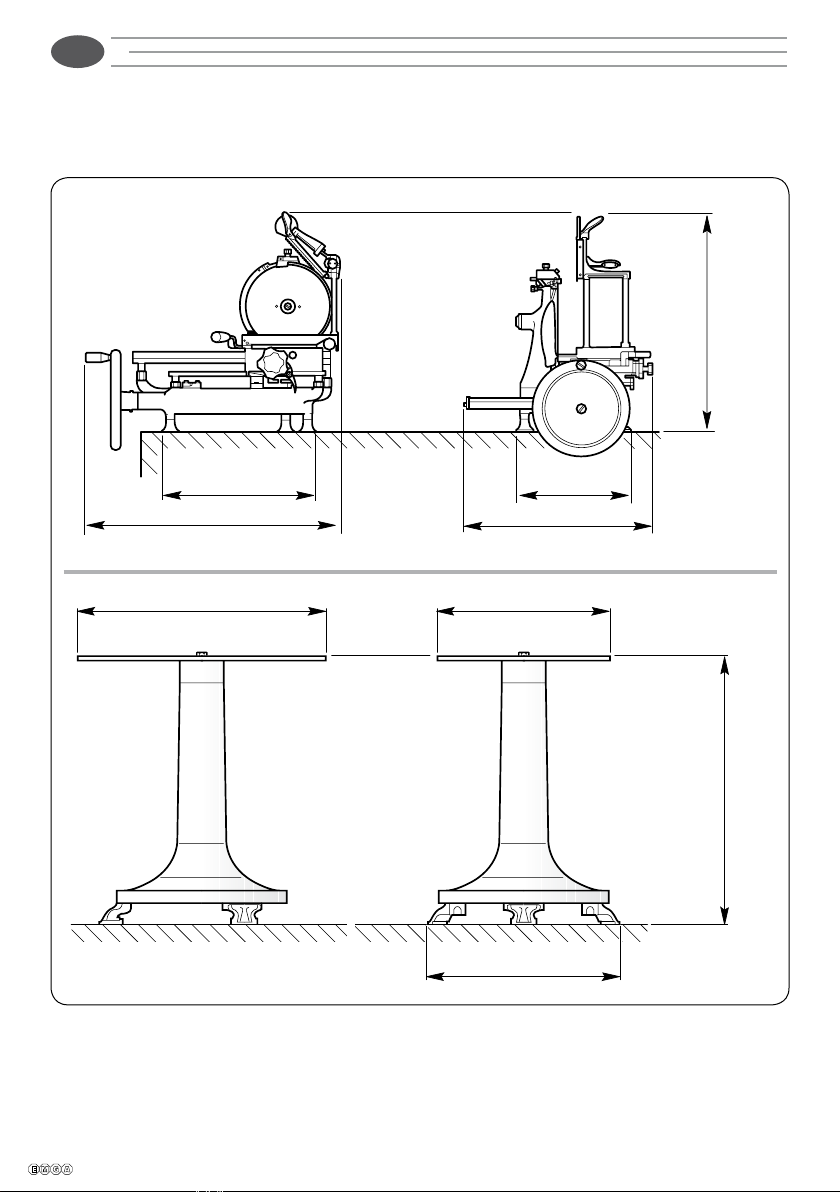

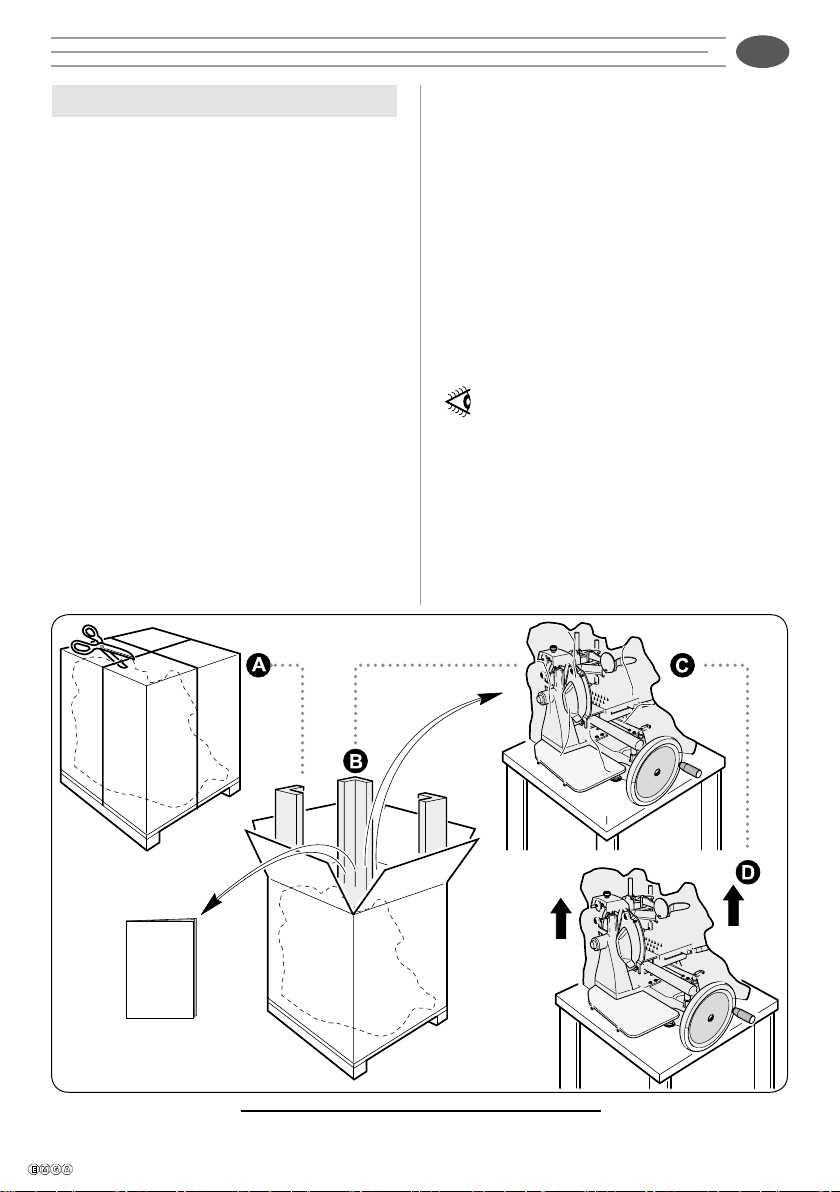

• Install the machine in accordance with

the instructions given under the heading

“Installation”.

•Install the machine in an area that cannot

be accessed by people who will not be

using it, especially children.