Facnor

FlatDeck furlin

& reefin

systems

Installation manual

e

Congratulations, you have purchased a Facnor reefing system. Over 20 years Facnor has

gained an excellent reputation in manufacturing furling systems that feature Innovation and

Reliability. Sturdy and easy-to-use, your Facnor reefing system will give you satisfaction

when either cruising or racing.

TABLE OF CONTENTS

1- Assembly drawing ........................................................................................ p. 18

2- Package inventory ....................................................................................... p. 18

2.1 – Box content .......................................................................................... p. 19

2.2 – Tube content ........................................................................................ p. 20

2.3 – Determining which section length should be used .................................... p. 20

3- Pre-installation notes .................................................................................... p. 21/22

4- Assembly stages .......................................................................................... p. 23

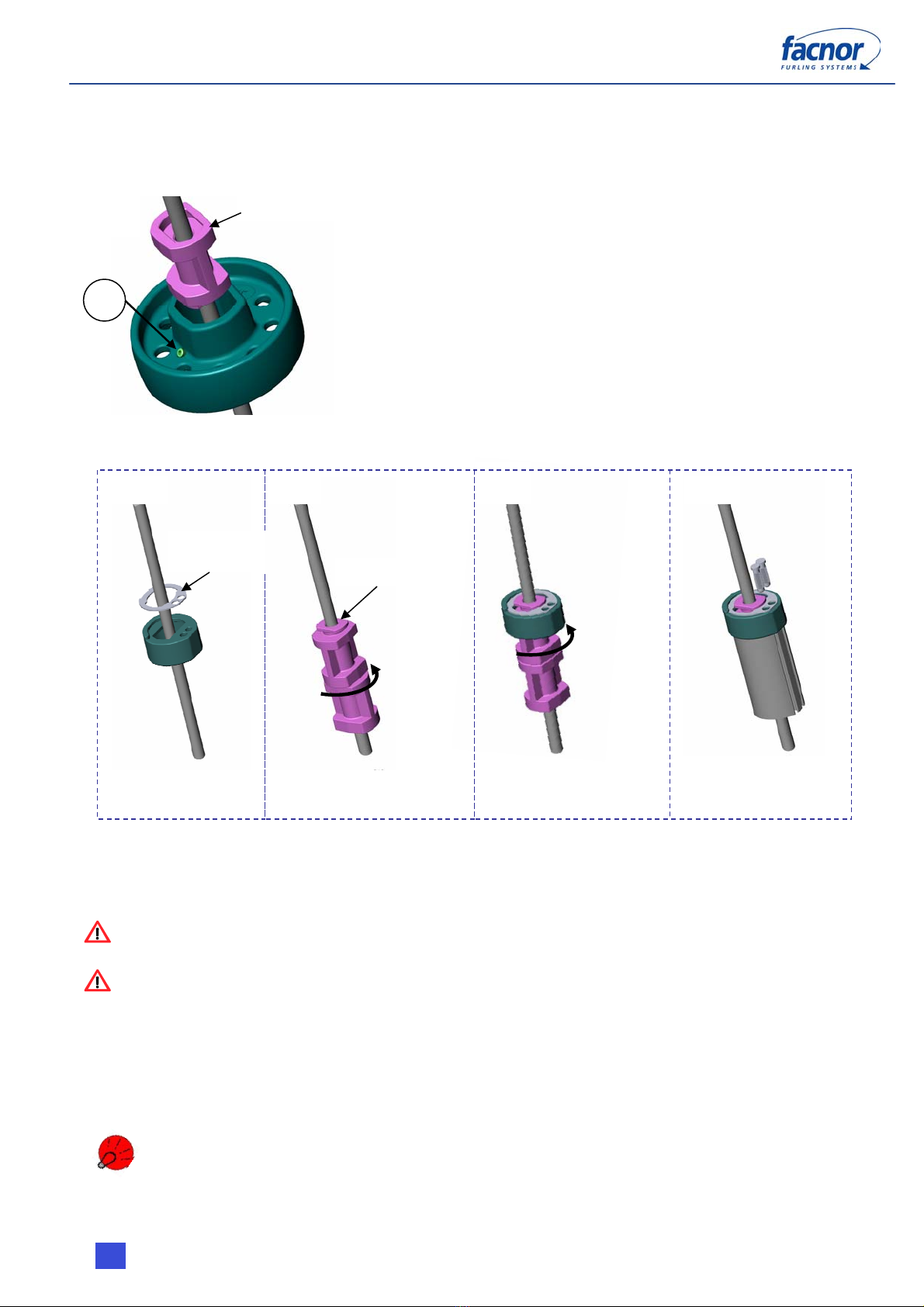

4.1 – Assembly of the halyard deflector ........................................................... p. 23

4.2 – Assembly of the top cap and the top section ............................................ P. 23

4.3 – Fitting the halyard swivel ....................................................................... p. 24

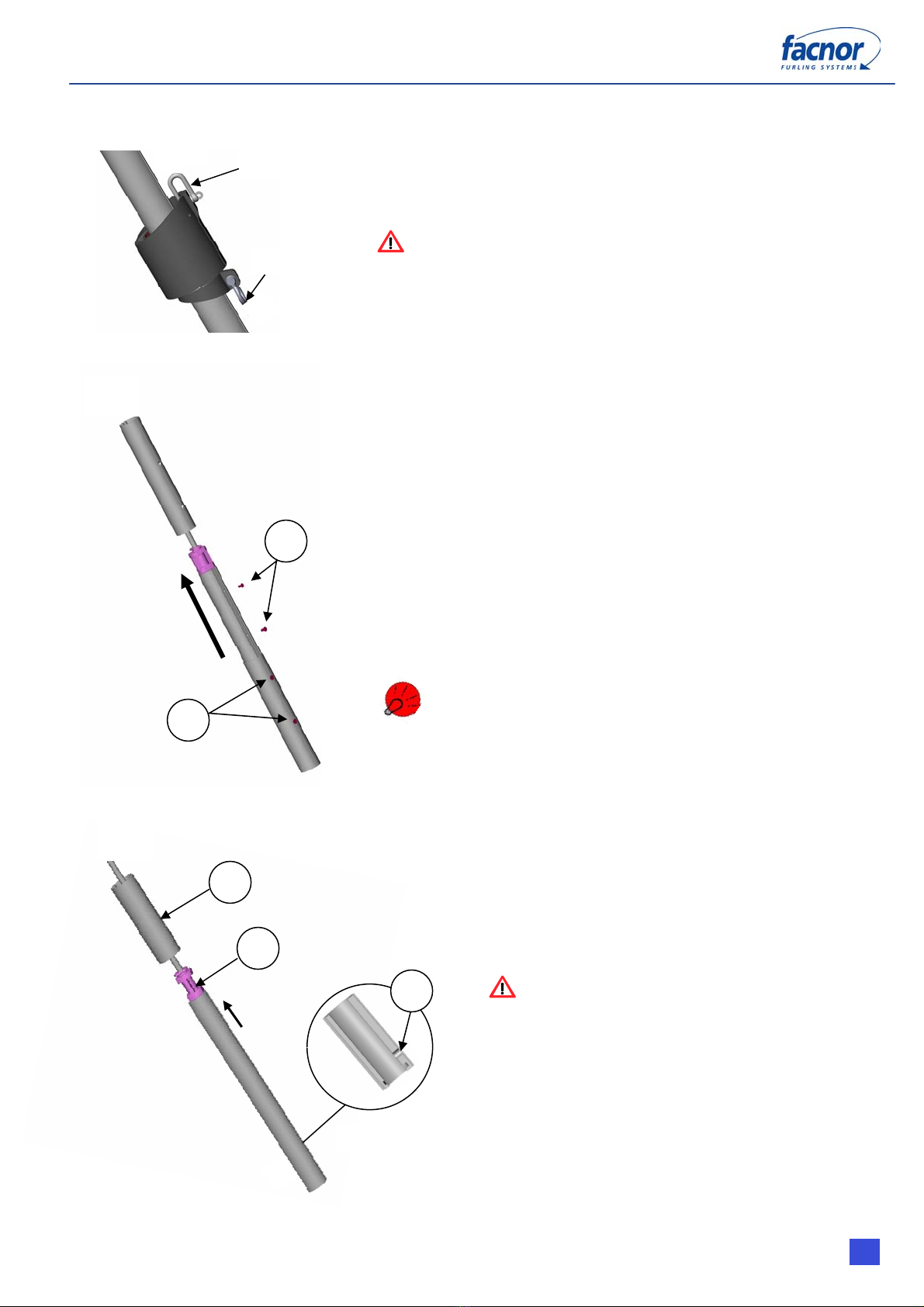

4.4 – Assembling foil sections ......................................................................... p. 24

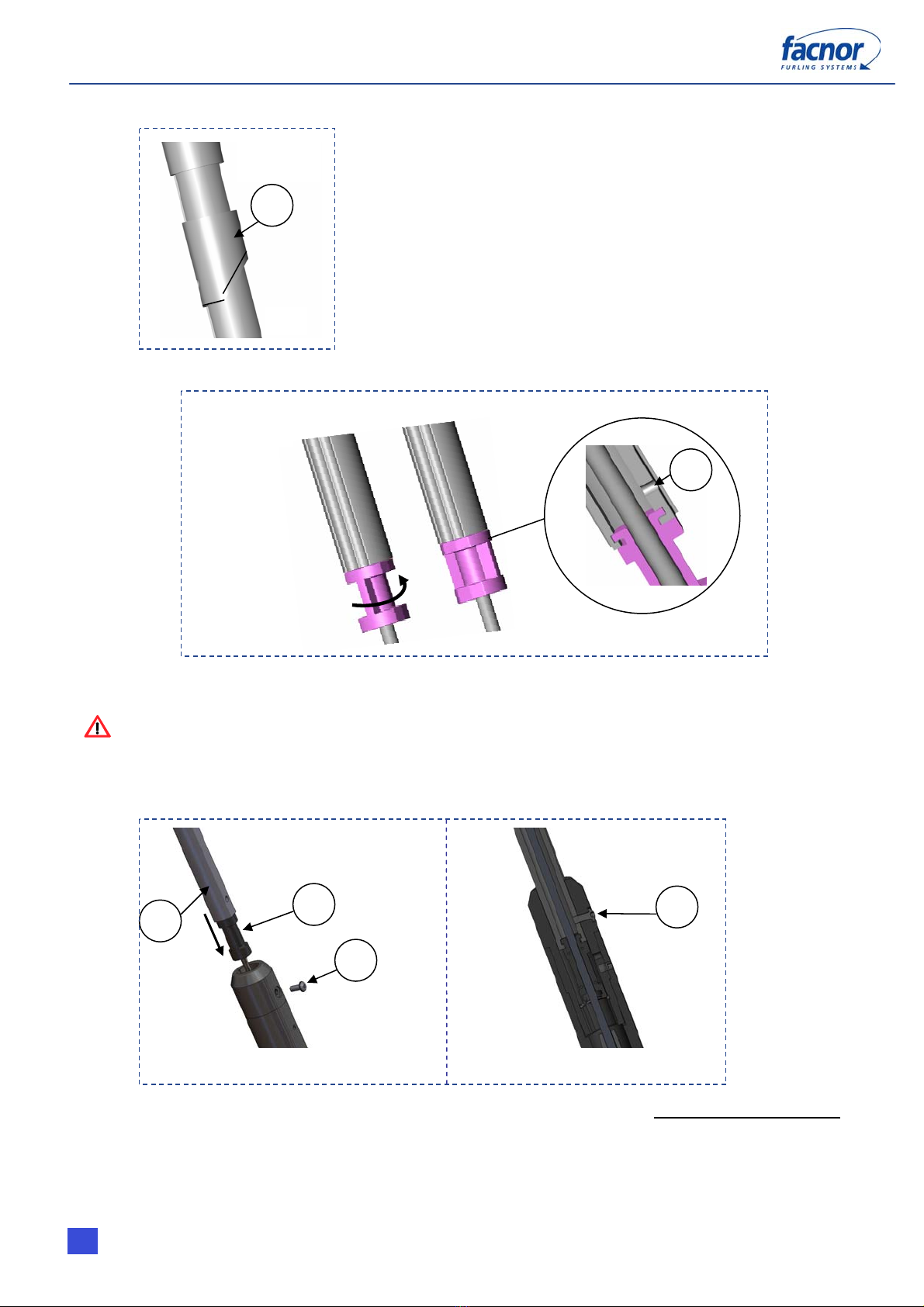

4.5 – Fitting the telescopic section .................................................................. p. 24

4.6 – Fitting the feeder .................................................................................. p. 25

4.7 – Fitting the bushing into the telescopic section .......................................... p. 25

4.8 – Fixing the telescopic section in the drum ................................................. p. 25

4.9 – Fixing the bottom of the drum ................................................................ p. 26

4.10 – Adjusting sections ................................................................................ p. 27

4.11 – Fixing the sail feeder ............................................................................ p. 27

5- Installation of the reefing line/webbing .......................................................... p. 28

5.1 – Fitting the reefing line/webbing .............................................................. p. 28

5.2 – Fitting the 1st lead block ........................................................................ P. 28

5.3 – Cutting the webbing .............................................................................. p. 28/29

5.4 – Fitting the webbing into the drum ........................................................... p. 29

6- Adjusting the furling line guide ..................................................................... p. 29

7- Specific installations ..................................................................................... p. 30

8- Furling tips .................................................................................................. p. 31

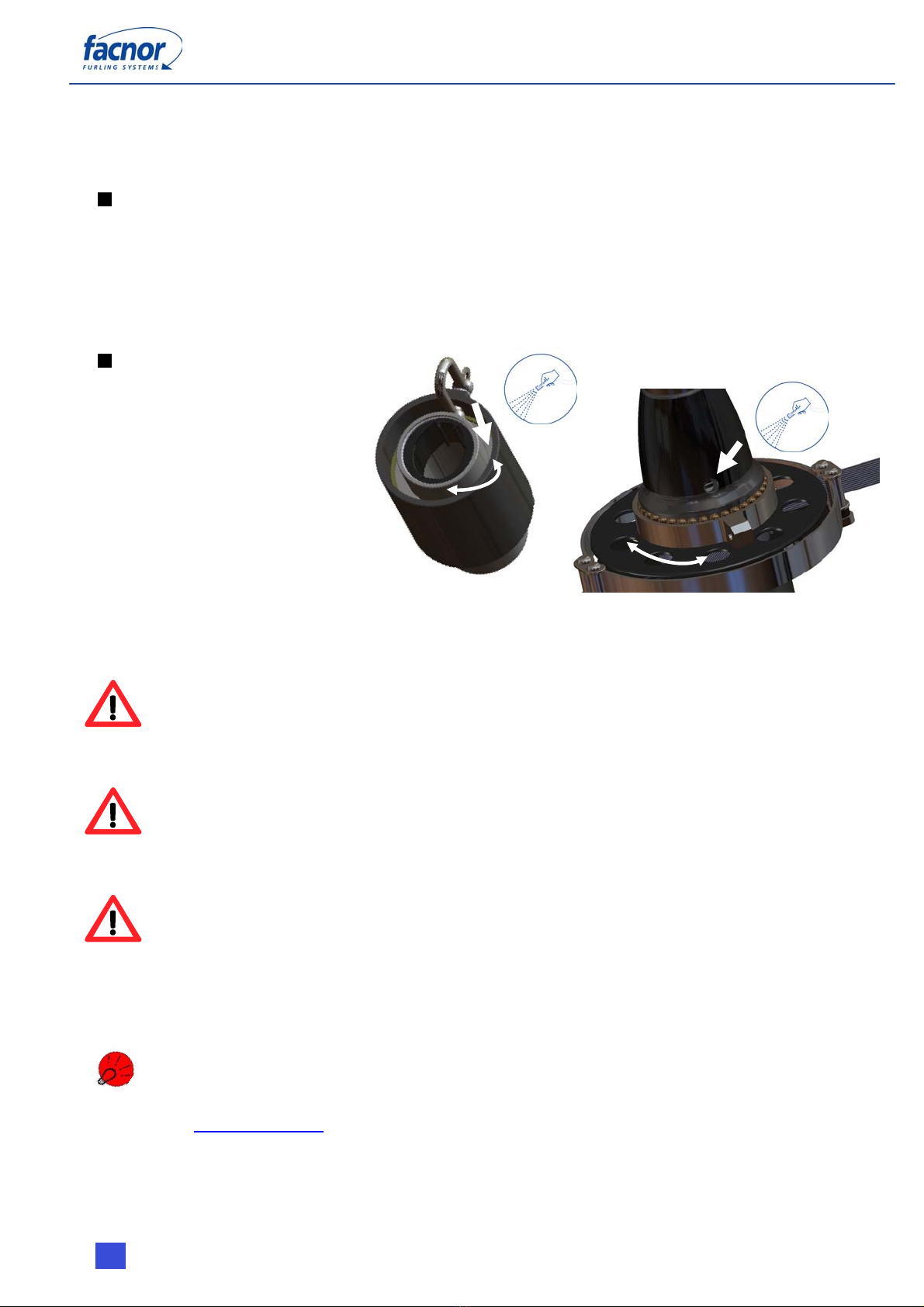

Before beginning assembly, we recommend that you read these instructions

carefully so as to familiarize yourself with the parts, installation and the use of

your Facnor furling and reefing system.

18

English