Factoryfurniture BOORT seat Manual

Other Factoryfurniture Outdoor Furnishing manuals

Factoryfurniture

Factoryfurniture OH bench Manual

Factoryfurniture

Factoryfurniture Serpentine Bench Manual

Factoryfurniture

Factoryfurniture Bloc Concrete Bench Manual

Factoryfurniture

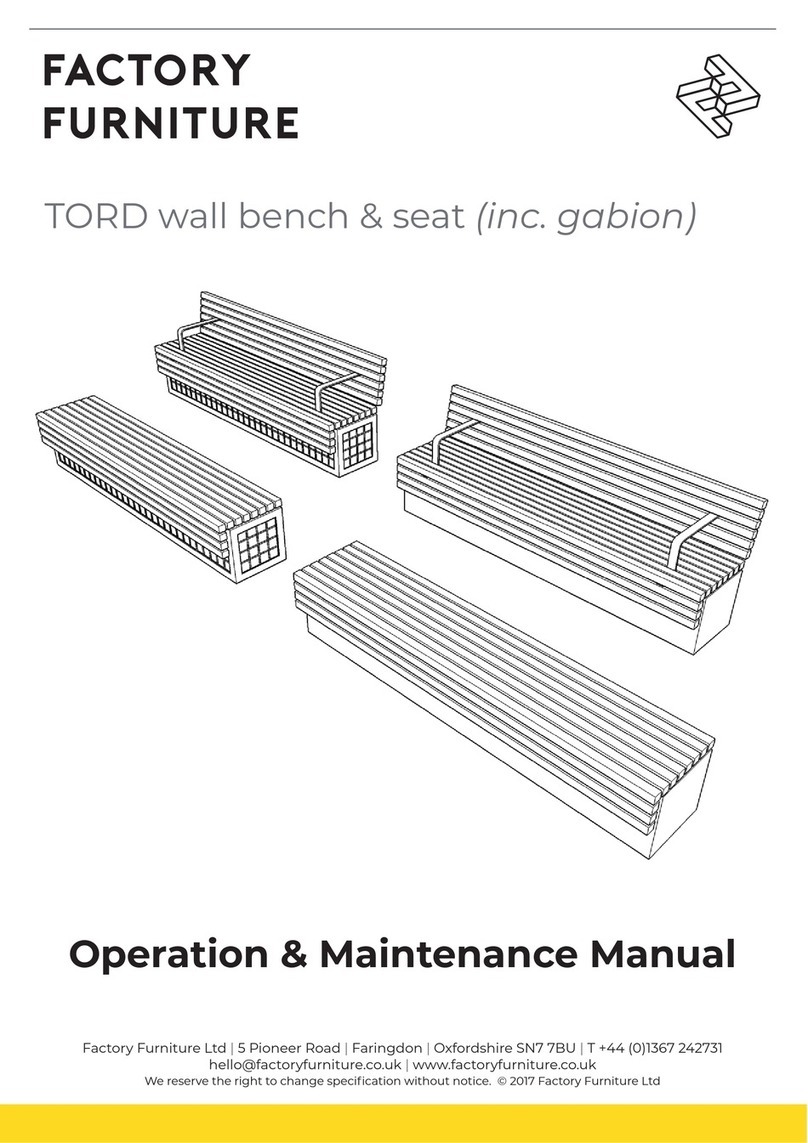

Factoryfurniture TORD Wall Bench & Seat Manual

Factoryfurniture

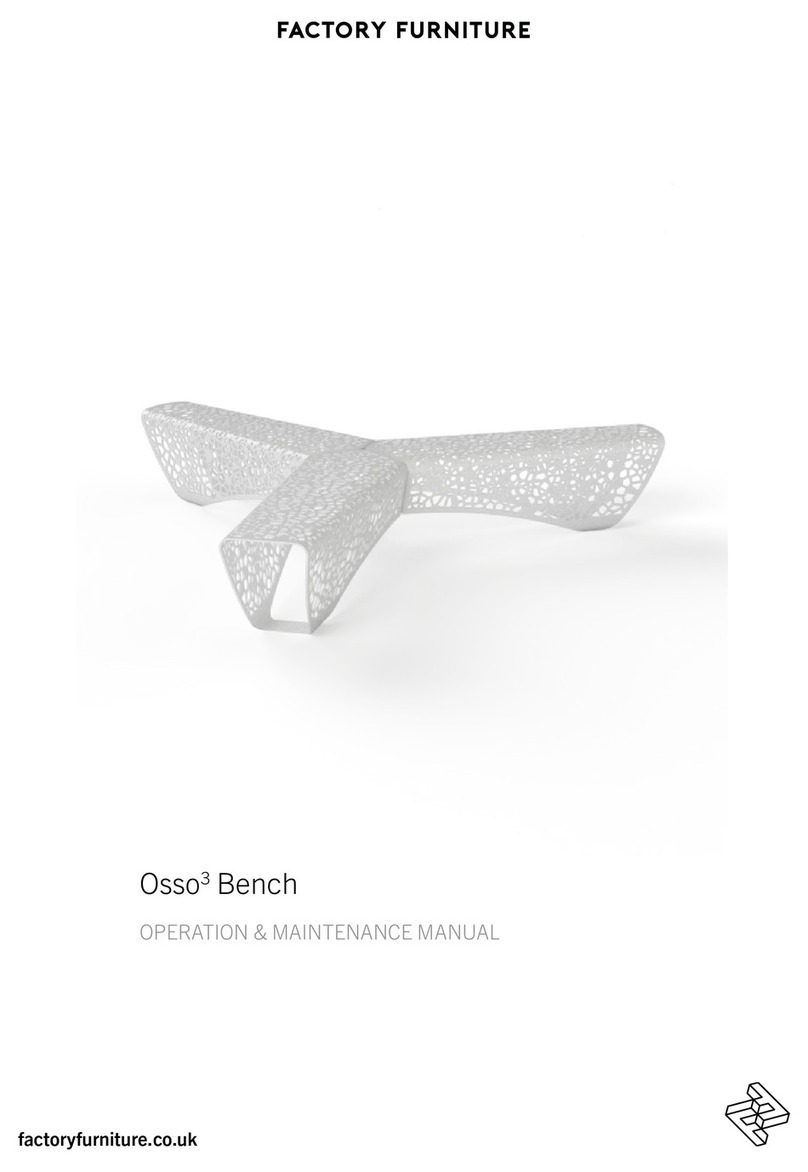

Factoryfurniture Osso3 Manual

Factoryfurniture

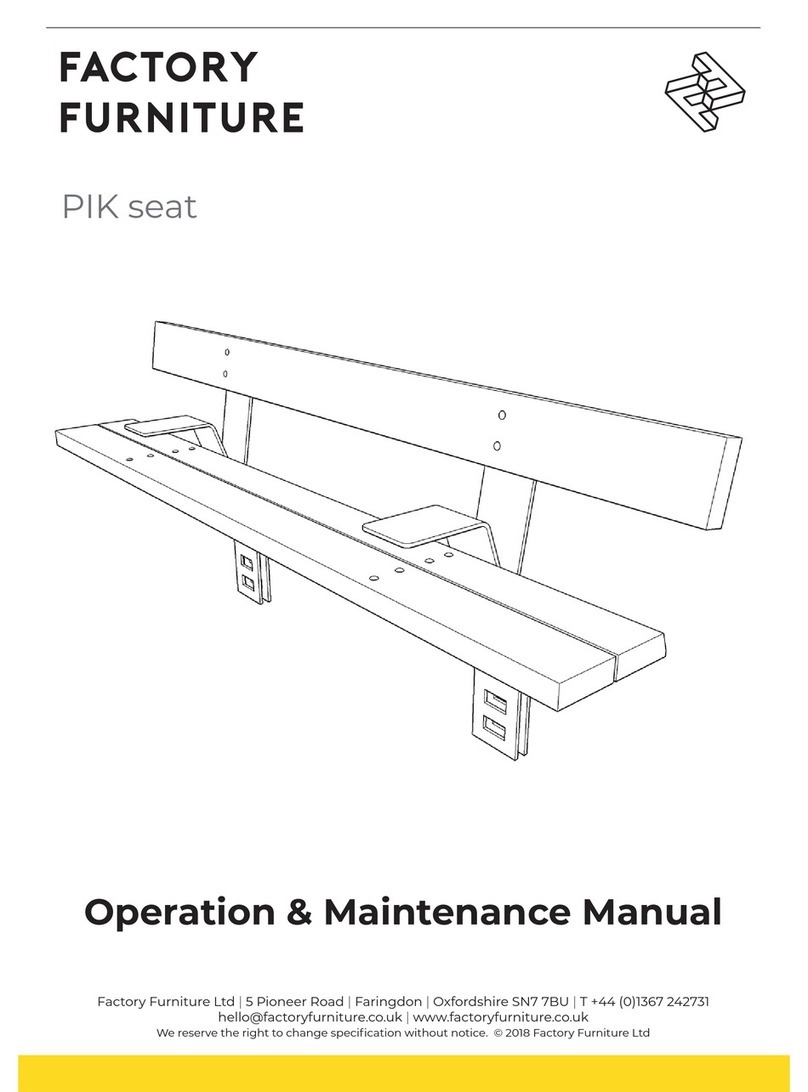

Factoryfurniture PIK seat Manual

Factoryfurniture

Factoryfurniture 5 Slat SERPENTINE Manual

Factoryfurniture

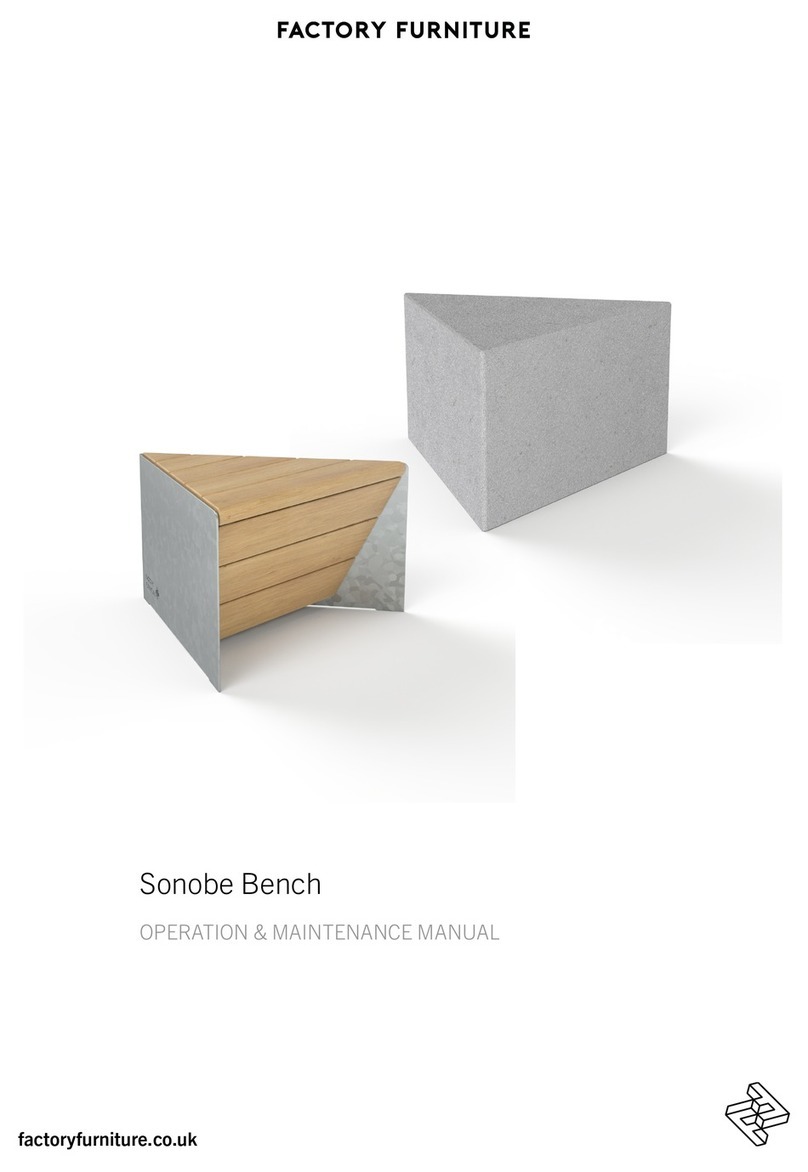

Factoryfurniture Sonobe Manual

Factoryfurniture

Factoryfurniture MANTIS seat Manual

Factoryfurniture

Factoryfurniture Foil Wood Bench Manual

Factoryfurniture

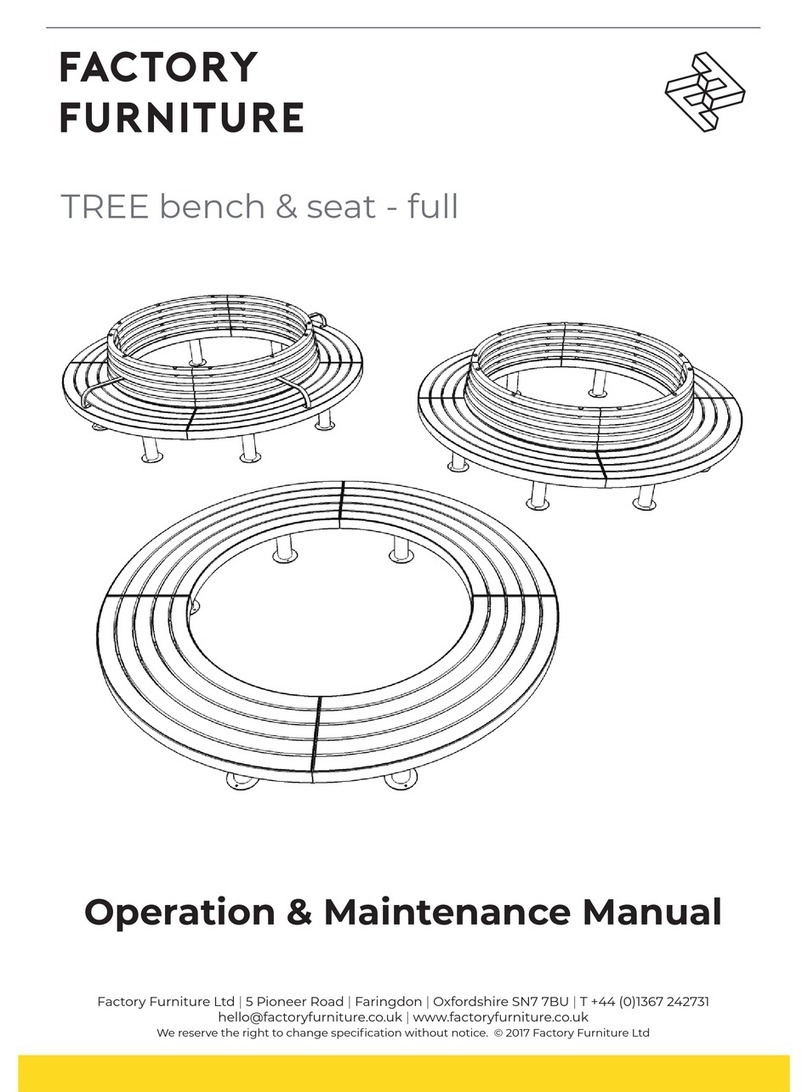

Factoryfurniture TREE Manual

Factoryfurniture

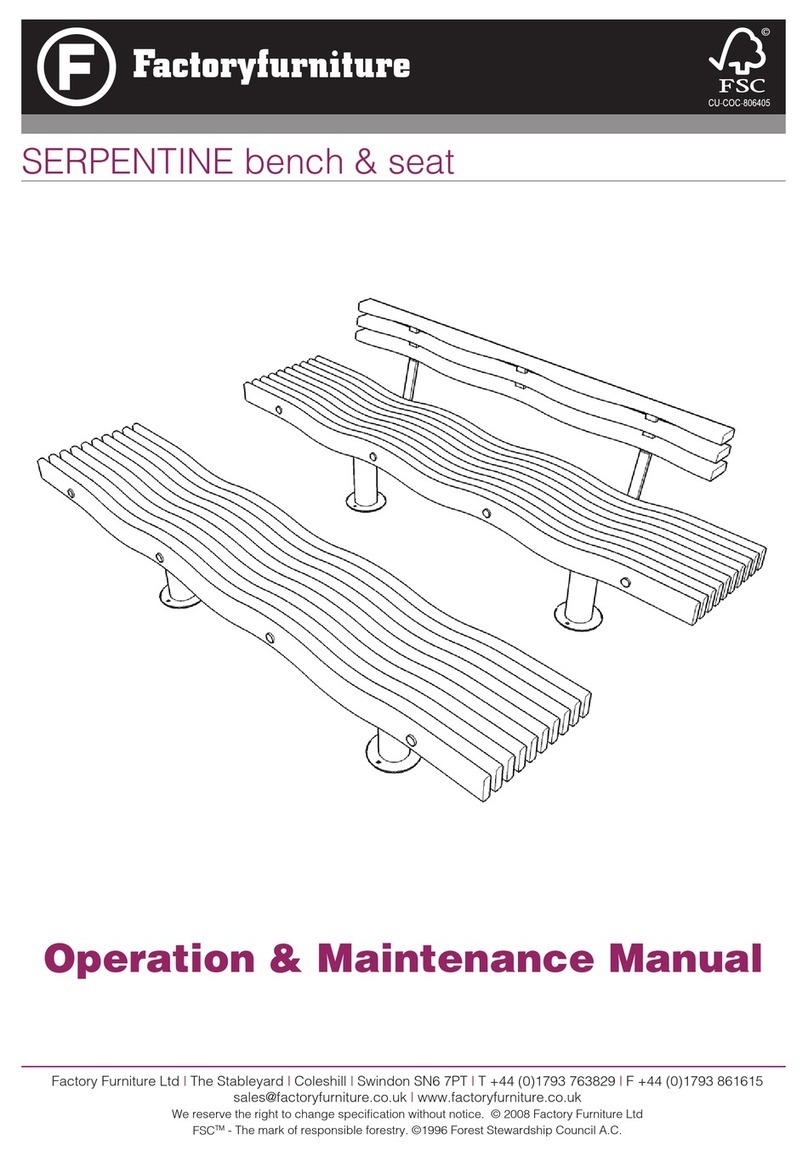

Factoryfurniture SERPENTINE Manual

Factoryfurniture

Factoryfurniture RAKT Manual

Factoryfurniture

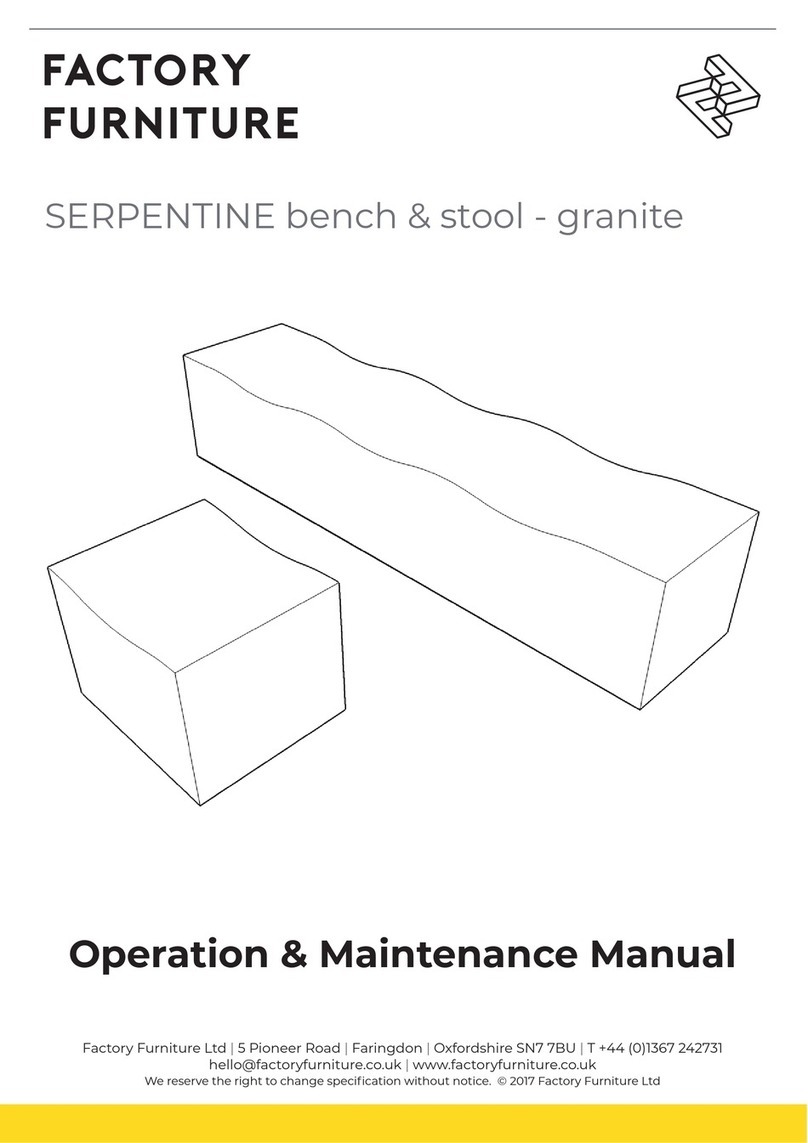

Factoryfurniture SERPENTINE Manual

Factoryfurniture

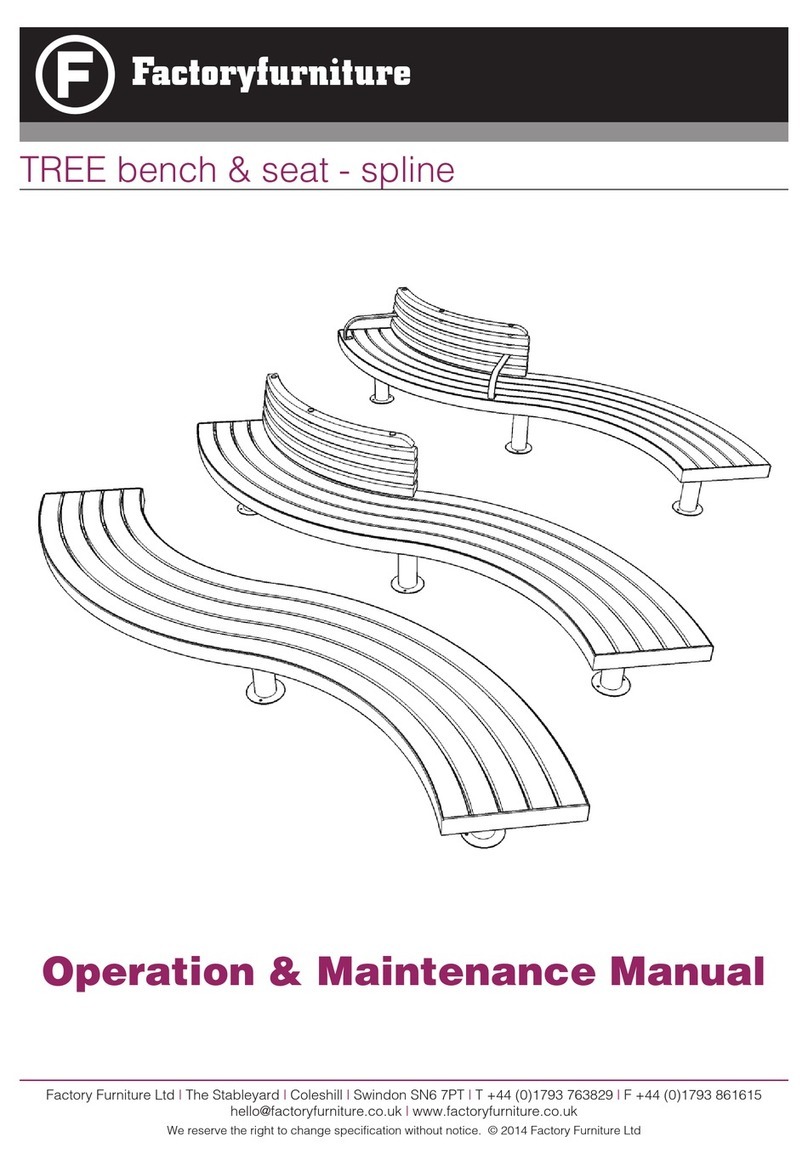

Factoryfurniture SPLINE TREE Manual

Factoryfurniture

Factoryfurniture TREE planter Manual

Factoryfurniture

Factoryfurniture Chronos Manual

Factoryfurniture

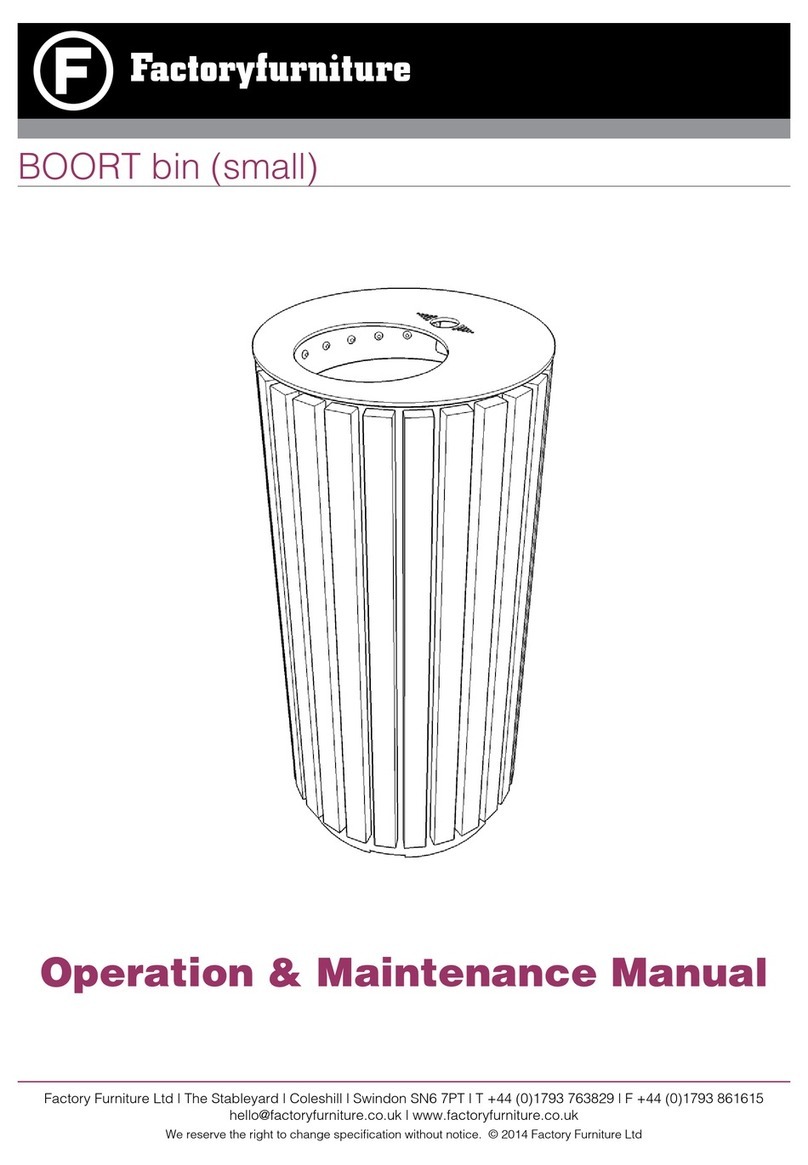

Factoryfurniture BOORT bin small Manual

Factoryfurniture

Factoryfurniture UTIL bench Manual

Factoryfurniture

Factoryfurniture PIK Manual

Popular Outdoor Furnishing manuals by other brands

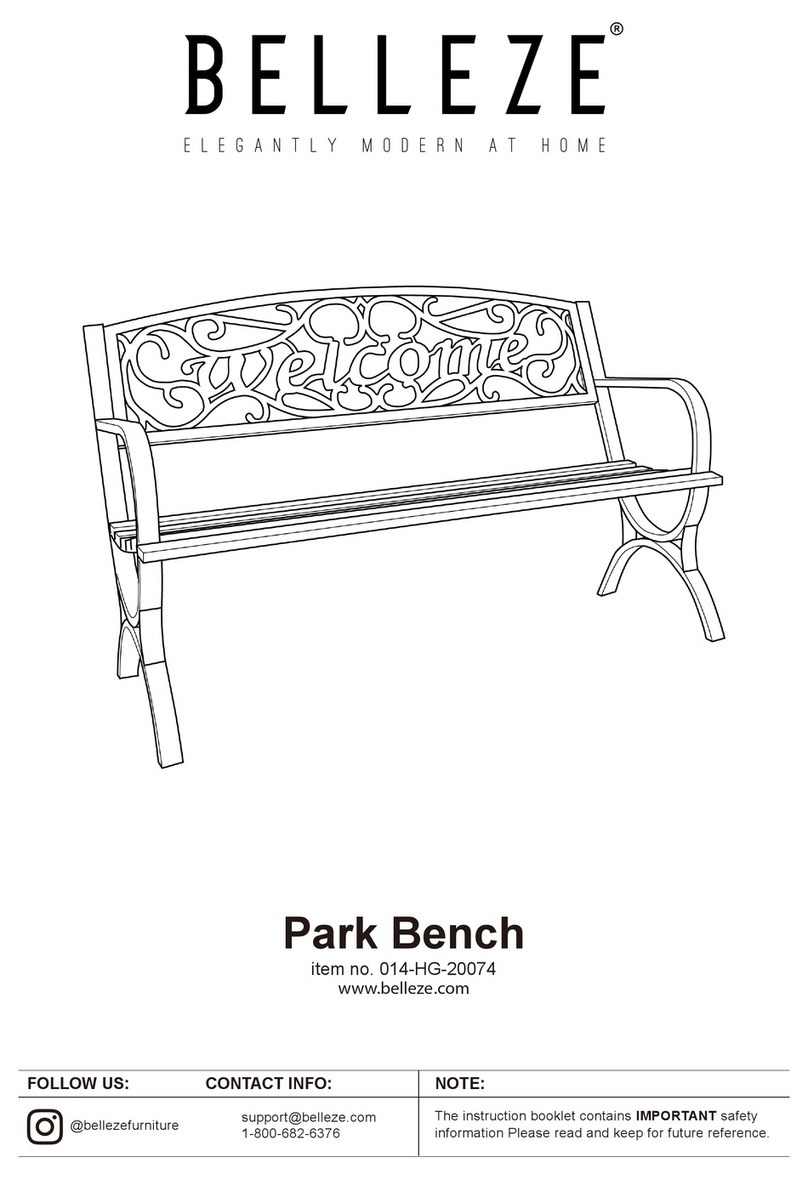

Belleze

Belleze 014-HG-20074 manual

Hatteras Hammocks

Hatteras Hammocks DCA1-K-HH instructions

Kozyard

Kozyard Morgan Aluminum Pergola Assembly manual

Lemeks

Lemeks Palmako PA120-5959 Assembly, installation and maintenance manual

OLT

OLT 24 Assembly manual

forest-style

forest-style HACIENDA 2354 Building instructions

Courtyard Creations

Courtyard Creations RUS0188-WM Assembly instructions

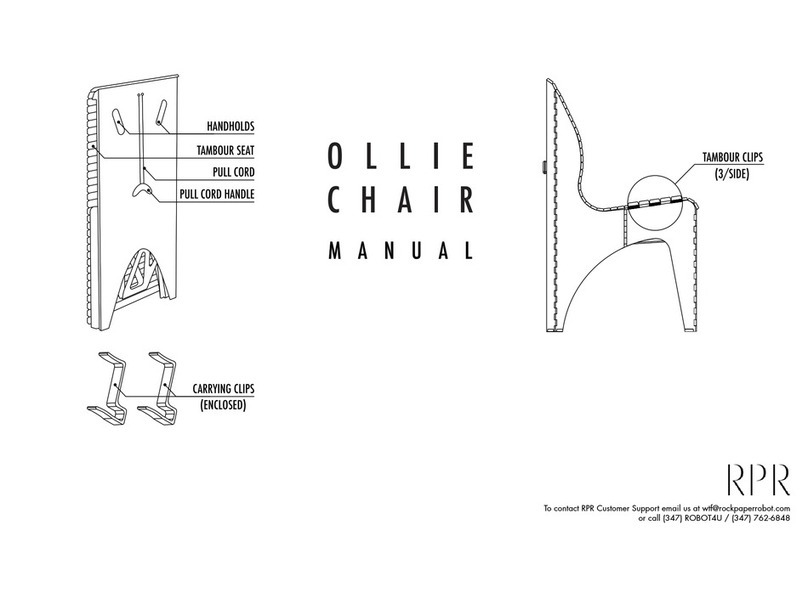

RPR

RPR OLLIE CHAIR manual

kingsley-bate

kingsley-bate MC-55 Assembly instructions

Weltevree

Weltevree Carrier product manual

Grange Fencing

Grange Fencing Elite Arch Assembly instructions

Grosfillex

Grosfillex AUVENT YR14 Assembly instructions