Introduction

Design

Design, shop drawings and development by Factory Furniture Ltd

Manufacture

Factory Furniture manufactured components. Products are assembled in Factory workshops, checked and dispatched ready

for installation. Replacement products or components thereof should be ordered direct from Factory Furniture Ltd

Copyright

The design copyright for the product and drawing copyright remains the sole property of Factory Furniture Ltd

General Specifications

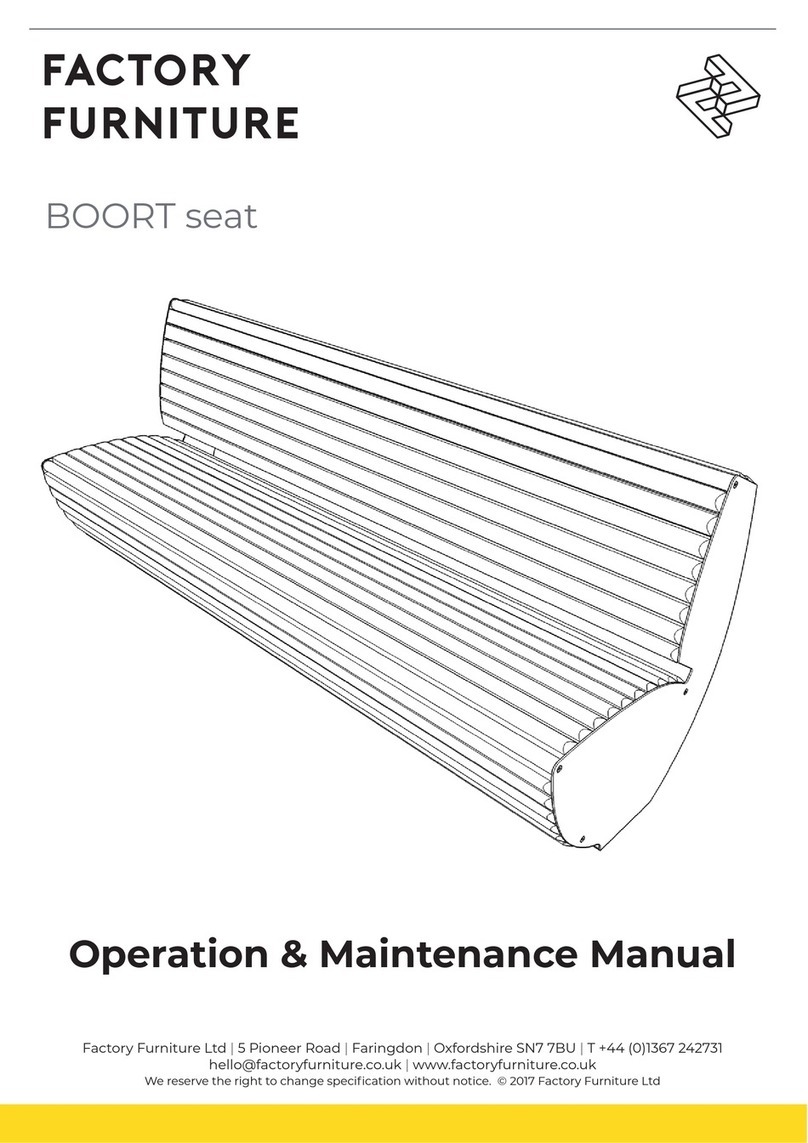

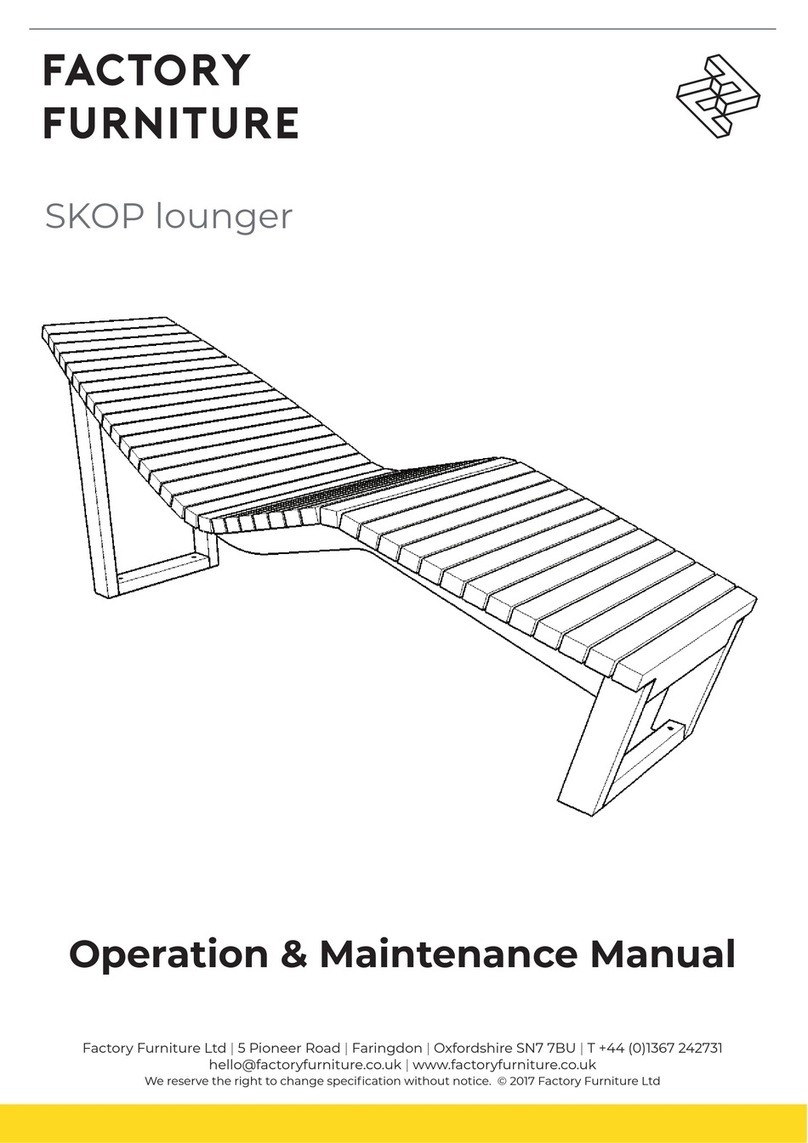

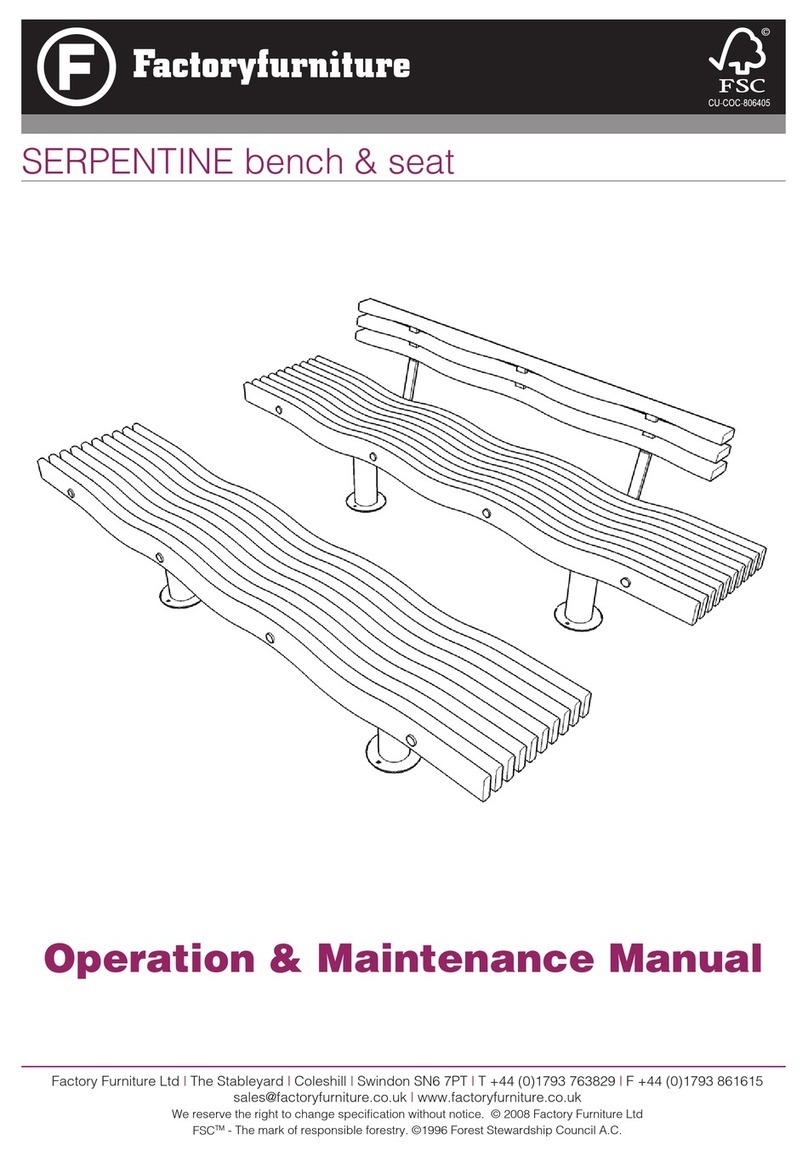

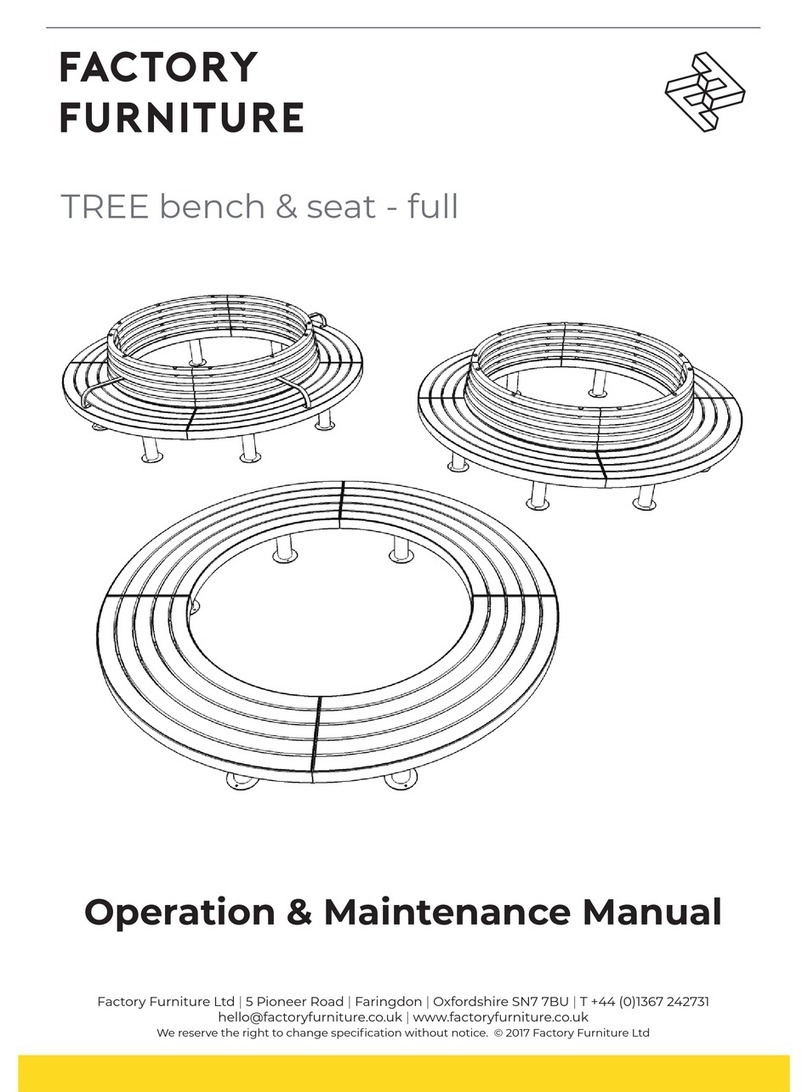

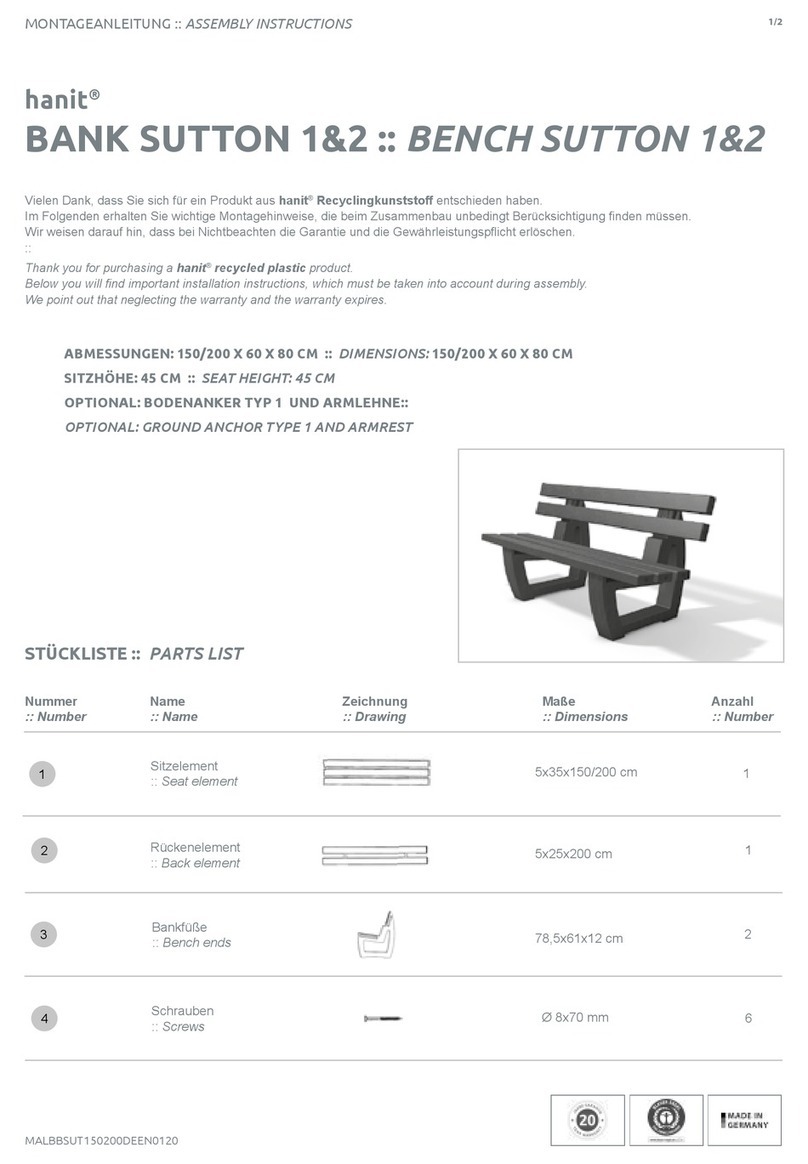

Spline Bench Spline Seat (with back)

Metric length 3400mm | width 1020mm | height 450mm* Metric length 3400mm | width 1020mm | height 790mm*

Imperial length 11’ 2” | width 3’ 4” | height 1’ 5½” Imperial length 11’ 2” | width 3’ 4” | height 2’ 7”

* Not including +100mm below ground level for sub-surface fix option * Not including +100mm below ground level for sub-surface fix option

Approx Weight 99kg Approx Weight 128kg (+4kg for armrest option)

Fixing Centres 1270mm (4’ 2”) x 150mm (6”) - between Fixing Centres 1270mm (4’ 2”) x 150mm (6”) - between

each base (3 bases total) each base (3 bases total)

Detailed Material & Finish Specifications

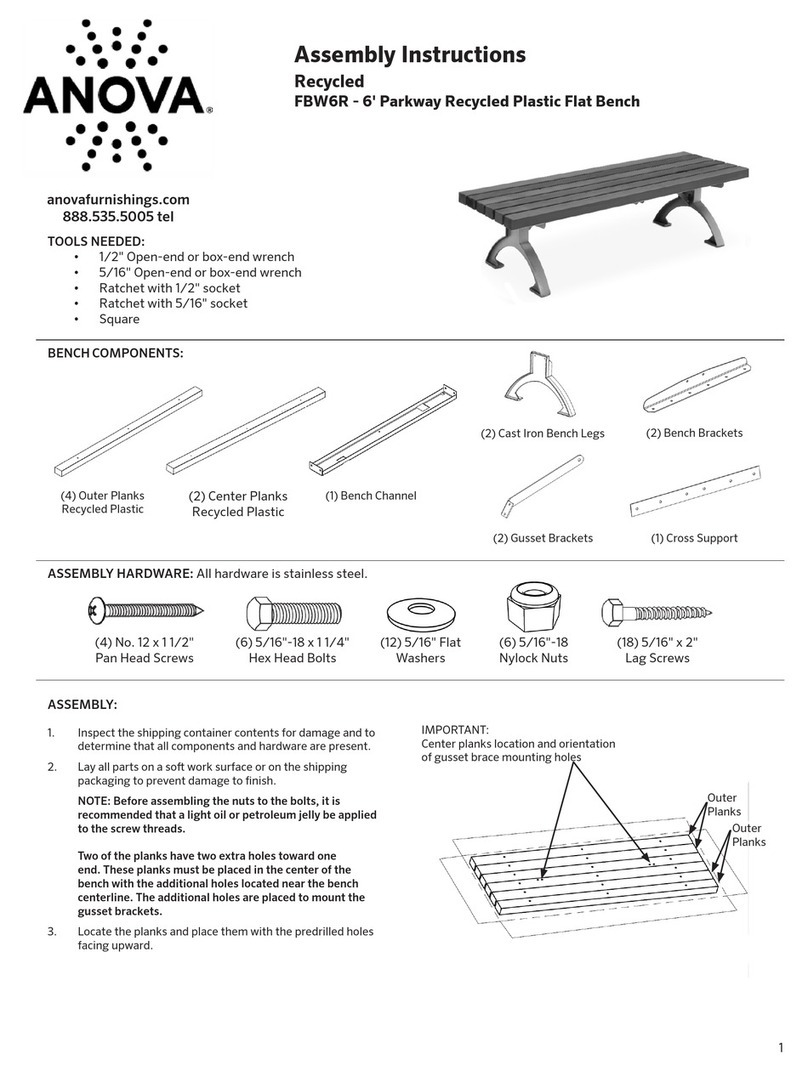

Bench Slats

• Manufactured from FSC®certified tropical hardwood (other FSC timber options available upon request)

• Profiled and left untreated as standard (oil or microporous woodstain treatment available on request)

• Bench slats supported by and fixed to frame with minimum 4 no. fixing points per slat

Backrest Slats (Seat only)

• Manufactured from FSC®certified tropical hardwood (other FSC timber options available upon request)

• Profiled and left untreated as standard (oil or microporous woodstain treatment available on request)

• Backrest slats held together and fixed to seat with 3 no. concealed zinc-coated mild steel threaded tie rods. Slats separated

on tie rods by aluminium spacers and fastened on top by aluminium end caps and underneath by M12 locknuts

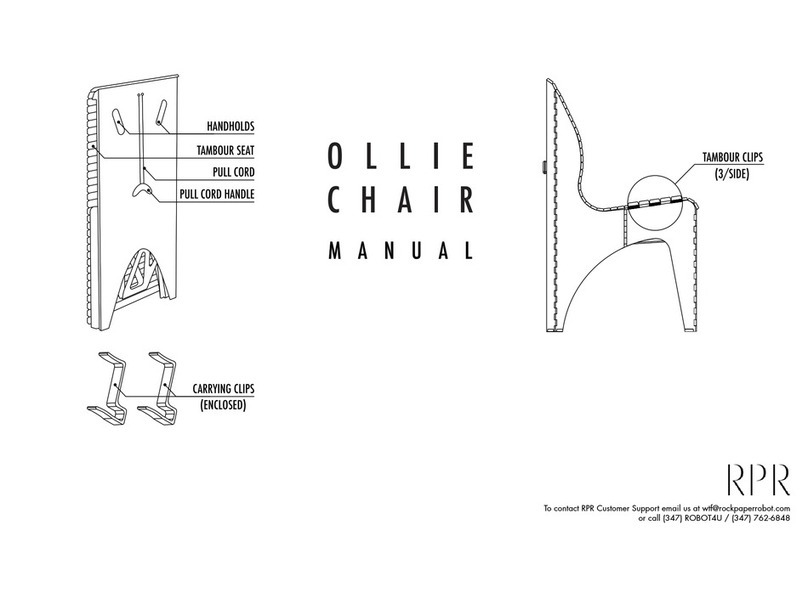

Bases / Frame / Armrests (Armrest optional - for seat only)

• Frame, bases and armrests manufactured from stainless steel with satin polished finish

• Bases fixed to frame with 2 no. M10 x 25mm button head bolts and locknuts per base (3 bases per bench / seat)

• Anchored using 2 no. resin fixed M10 x 200mm threaded rods and cap nuts per base (surface fix) or 2 no. zinc-coated

steel M10 x 75mm sleeve anchors per base (sub-surface fix)

• Where armrests are included they are threaded onto the tie rods at one end and fixed at the other end to the outer seat slat

with 2 no. fixing points. There are 2 no. armrest per seat as standard

General Maintenance (Recommended Schedule & Guidelines)

Daily/Weekly/Monthly (or as adopted)

Visual checks of bench / seat top, back and bases - check all items for superficial or physical damage.

Three Monthly

Clean all items as detailed below check all fixings are seated correctly; inspect timber for serious damage and splinters.

Six Monthly

Secure all fixings; full clean as detailed below; check that bench / seat is firmly secured to the ground

Specific Maintenance Details

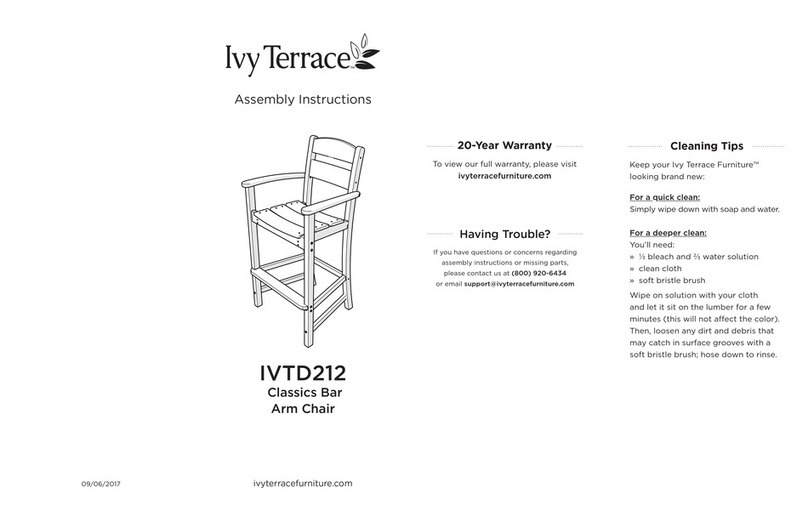

FSC Timber

Clean with a stiff brush once per year, especially in more exposed locations, in order to prevent a verdigris type build up on

the timber surface. Ideally this should be completed in early spring. During the cleaning stage, all exposed timber surfaces

should be inspected for splits and splinters. Any splinters and graffiti should be removed and the surface sanded with 100

grit sandpaper in order to remove any uneven / sharp edges or surfaces.

During the first few months after installation the tannin naturally occurring in the timber may leach out and cause a brown

staining on the bases. This may be removed with a light solution of household bleach and water.

Stainless Steel (polished stainless steel only)

Clean as required, but at least every three months, using a stainless steel polish and a lint free cloth. To remove ground in dirt,

a stainless steel finishing pad may be required.

2SPLINE TREE specification

)6&&

5HVSRQVLEOH

)RUHVW0DQDJHPHQW