Specific Maintenance Details

FSC Timber

Clean with a stiff brush once per year, especially in more exposed locations, in order to prevent a verdigris type

build up on the timber surface. Ideally this should be completed in early spring. During the cleaning stage, all

exposed timber surfaces should be inspected for splits and splinters. Any splinters and graffiti should be removed

and the surface sanded with 100 grit sandpaper in order to remove any uneven / sharp edges or surfaces.

During the first few months after installation the tannin naturally occurring in the timber may leach out and

cause a brown staining on the bases. This may be removed with a light solution of household bleach and water.

Stainless Steel (polished stainless steel only)

Clean as required, but at least every three months, using a stainless steel polish and a lint free cloth. To remove

ground in dirt, a stainless steel finishing pad may be required.

Repairs

FSC Timber

For light damage, please see section on specific maintenance details above. For instances of heavy damage,

the timber item should be replaced. Please order against the part number reference in the reordering section

towards the end of this manual.

Stainless Steel

Light damage (surface scratches etc.) can be removed using an emery pad (240 grit) and freeing oil such as

‘WD40’. Care should be taken to follow the direction of the brushing grain. It is recommended that a trial repair

be carried out on an unimportant surface first. No corrosive cleaners or other abrasives should be used. Any

contamination, particularly carbon steel scuffs from vehicles, should be quickly removed to avoid corrosion.

Heavy Damage

In the event of serious damage to any component, replacements should be ordered from Factory Furniture Ltd.

In this event (or if the product needs to be disassembled for any reason), please contact Factory Furniture for

detailed technical advice.

Reordering / Spares

Part No. Item Description

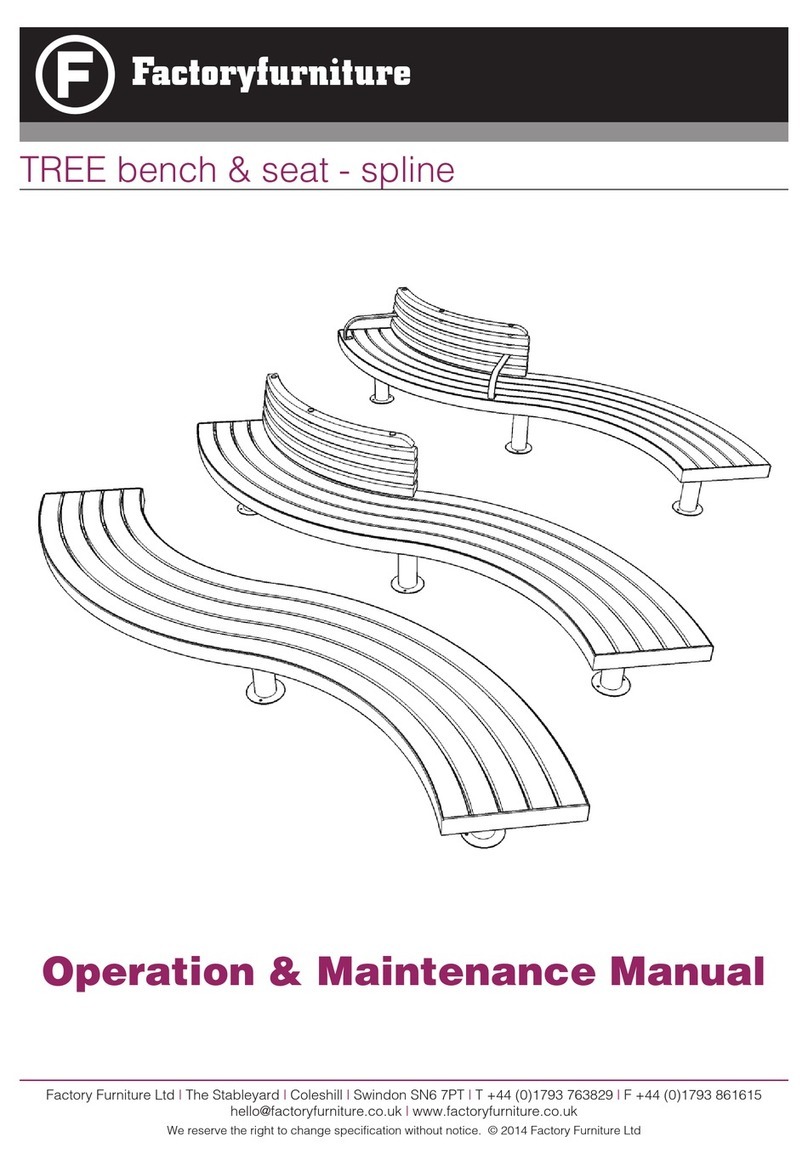

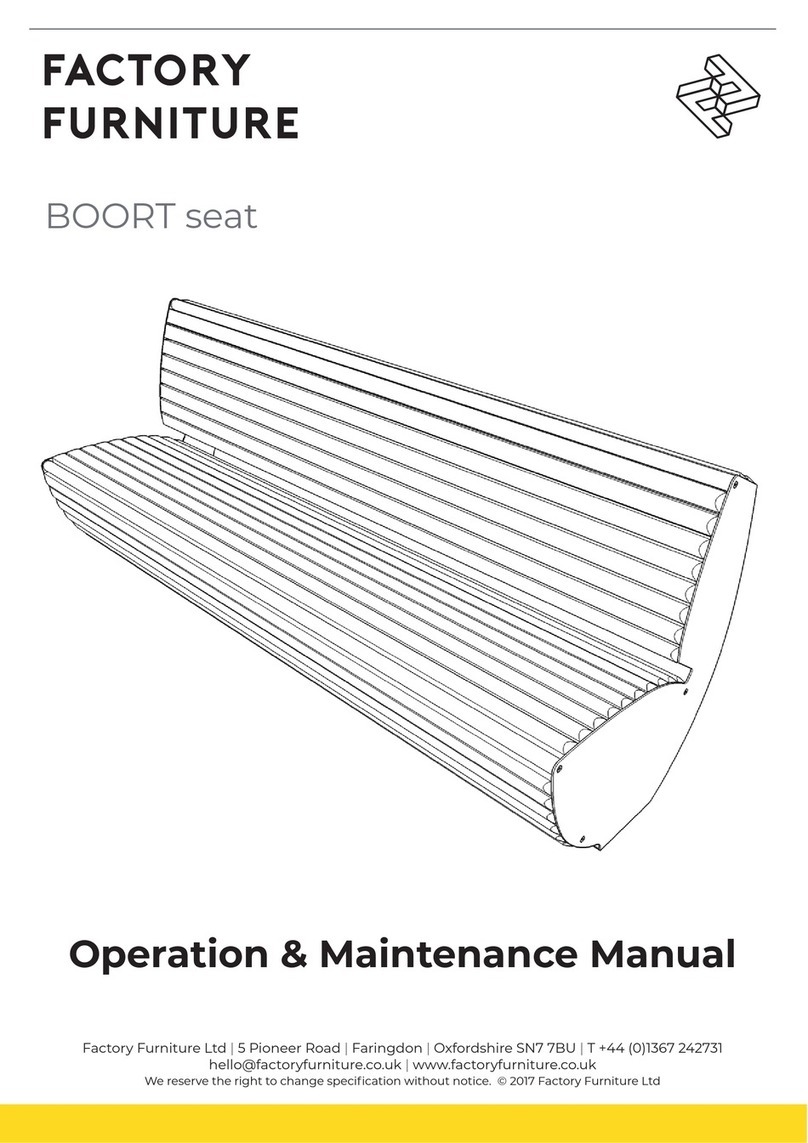

P1030 / 01 1 no. Quarter module bench slat set - includes bench slats (15 slat parts in total)*

P1030 / 02 1 no. Quarter module backrest slat set (seat only)- (10 slat parts in total)*

P1030 / 03 1 no. Backrest fixing set (includes endcap, 5 no. spacers and threaded rod)

P1030 / 04 1 no. Tree seat base (please specify surface or sub-surface fix) - suitable for bench & seat

*N.b. 4 no. quarter module slat sets are required to replace all slats on complete bench / seat

Instructions For Reordering

If possible, please specify job name or number at the time of reordering to enable identification of details such

as the original species of timber used, stainless steel finishes and polyester powder coat colours etc. In any

event where either, additional orders are required, or spares and replacements are required please contact

Factory Furniture Ltd. Using the part numbers given above as reference should help us to process your enquiry

more efficiently.

Note - All fittings required to assemble ordered parts will automatically be included in the order.

AutoCAD Drawing List

FF1030 / 01 FULL TREE BENCH OVERVIEW DRAWING

FF1030 / 02 FULL TREE SEAT (WITH BACK) OVERVIEW DRAWING

FF1030 / 03 FULL TREE BENCH / SEAT (WITH BACK) TYPICAL X-SECTION DRAWINGS

FF1030 / 04 FULL TREE BENCH / SEAT (WITH BACK) TIMBER BENCH SLAT SET PARTS DETAIL

FF1030 / 05 FULL TREE BENCH / SEAT (WITH BACK) TIMBER BACKREST SLAT SET PARTS DETAIL

FF1030 / 06 FULL TREE BENCH / SEAT (WITH BACK) STEEL FRAME PARTS DETAIL

FF1030 / 07 FULL TREE BENCH / SEAT (WITH BACK) BASE & BACKREST PARTS DETAIL

FF1030 / 08 FULL TREE BENCH / SEAT (WITH BACK) SET OUT DRAWING

FF1030 / 09 FULL TREE BENCH / SEAT (WITH BACK) OVERSIZE TEMPLATE DRAWING

FF1030 / 10 FULL TREE SEAT (WITH BACK) ARMREST OPTION

Contacts

Factory Furniture Ltd Tel +44 (0) 1367 242731

5 Pioneer Road Email hello@factoryfurniture.co.uk

Faringdon, Oxon Web www.factoryfurniture.co.uk

SN7 7BU UK

3FULL TREE maintenance