Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Cybersecurity............................................................................................ 7

2.4 Limitation of liability................................................................................. 7

2.5 Modifications and conversions................................................................ 8

2.6 Requirements for skilled persons and operating personnel.................. 8

2.7 Operational safety and specific hazards................................................. 8

2.8 UL conformity............................................................................................ 9

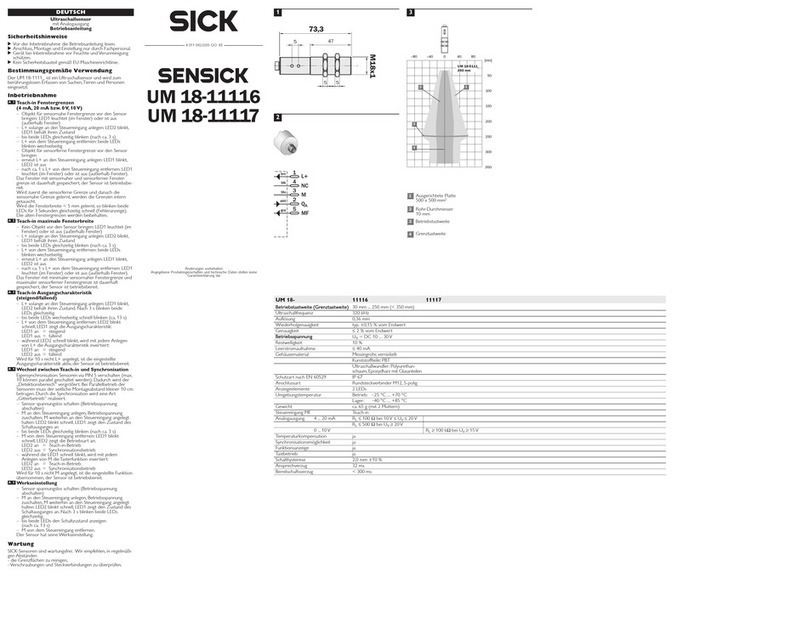

3 Product description........................................................................... 10

3.1 Scope of delivery....................................................................................... 10

3.2 Product ID.................................................................................................. 10

3.3 Type code.................................................................................................. 11

3.4 Product overview....................................................................................... 11

4 Transport and storage....................................................................... 12

4.1 Transport................................................................................................... 12

4.2 Unpacking.................................................................................................. 12

4.3 Transport inspection................................................................................. 12

4.4 Storage...................................................................................................... 12

5 Mounting............................................................................................. 13

5.1 Mounting instructions............................................................................... 13

5.2 Mounting distances.................................................................................. 13

5.3 Aligning the device.................................................................................... 13

5.4 Aligning device with alignment aid.......................................................... 13

6 Electrical installation........................................................................ 15

6.1 Wiring instructions.................................................................................... 15

6.2 Prerequisites for safe operation of the device........................................ 15

6.3 Pin assignment......................................................................................... 17

7 Operation............................................................................................ 20

7.1 Status indicators....................................................................................... 20

7.2 Digital output teach-in.............................................................................. 20

7.2.1 Factory settings of the digital output...................................... 20

7.2.2 Teaching in switching point (Single Point Mode)................... 20

7.2.3 Teaching in switching window (Window Mode)...................... 21

7.2.4 Teaching in background (Window Mode ±8%)...................... 21

CONTENTS

8016973/1K73/2023-06-21 | SICK O P E R A T I N G I N S T R U C T I O N S | UM12 3

Subject to change without notice