$it$

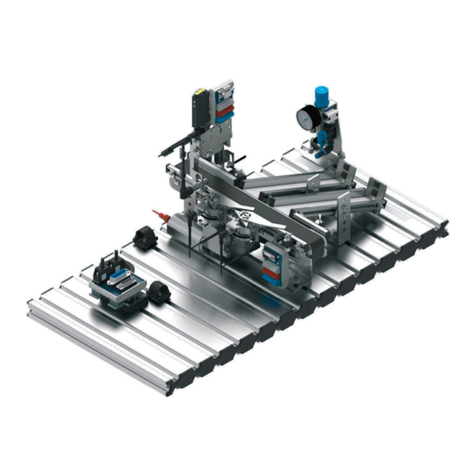

mounting for Festo cylinder

Anbau an

Festo-Zylinder

DNU-.

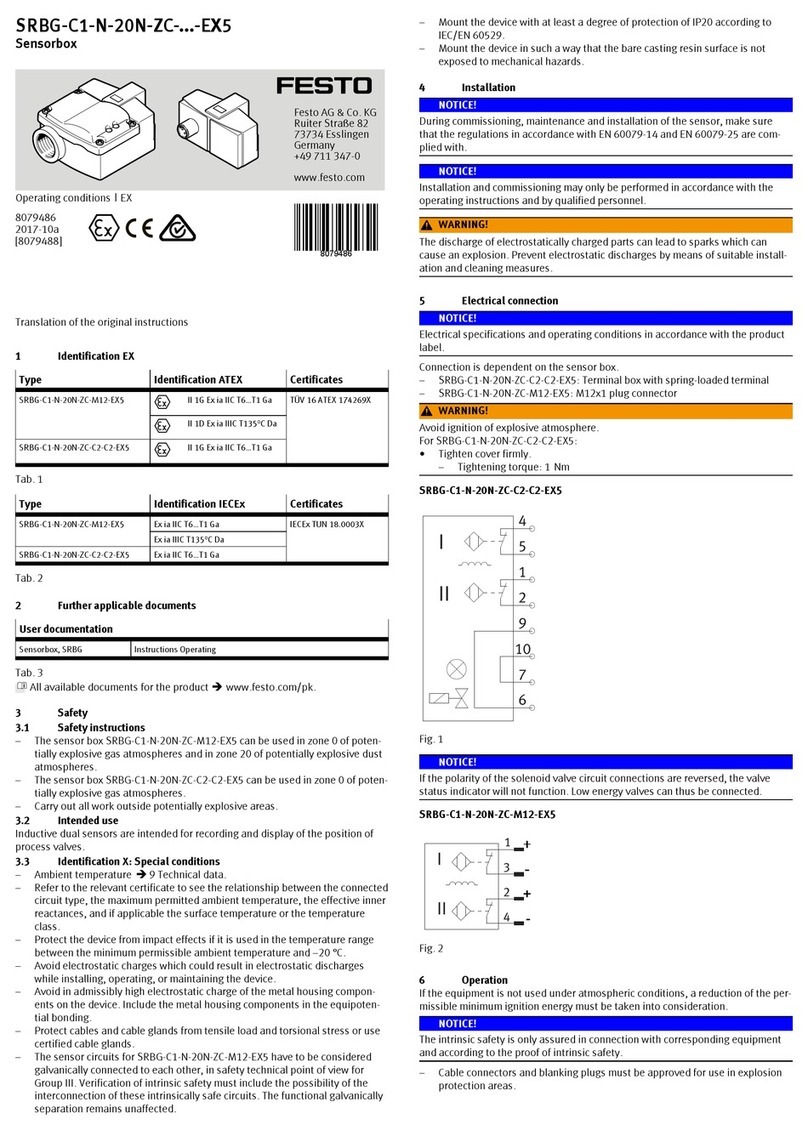

4. Startup

Move the cylinder to the end position.

Apply compressed air of between 29 to

87 psi

I2

to 6 bar to port

0.

Utilize port

@

for further signal

processing.

Example: input

‘IX”,

sequence control,

Festo Quickstepper.

Move the proximity switch until it reaches

the switching point (compressed air

signal at port

@

of the amplifier).

Position the proximity switch with the

screw and secure it with the threaded

pin.

-.

Operation

al

To block interference from adjacent

magnetic fields, a space of at least

0.79 in/20 mm must exist between ad-

jacent cylinder barrels, or between the

proximity switch and an adjacent barrel

or switch.

4. lnbetriebnahme

Zylinder in die Endlage fahren

Druckluft

2 bis 6 bar am

Anschlu8

@

anlegen

Ausgang

@fur

weitere

Signalverar-

beitung.

Beispiel: Eingang

,,X‘C

Ablaufsteuerung,

Festo Quickstepper.

Naherungsschatter

verschieben, bis

Schaltpunkt erreicht ist

(Druckluftsignal

am

Anschlu8

A des

Verstarkers).

Naherungsschalter

mit der Schraube

fixieren und mit Gewindestift

zusatzlich

sichern.

5.

Betrieb

a) Urn die Beeinflussung

durch

ein

be-

nachbat-tes Magnetfeld

auszuschlies-

sen,

mu8

ein

Sicherheitsabstand

von

mindestens 20 mm zwischen zwei

Zylinderrohren oder zum

Naherungs-

schalter eingehalten

werden.

Maximum passing speed when

sensing intermediate positions can be

approx. 3.8

ft/sec/l

m/s (without vol-

ume loads) and is a function of the cyl-

inder, devices that follow in the circuit,

length of tubing and pressure.

The switch must be 0.6 in/l

5

mm from

any steel components.

Port

@

must remain open.

b) Die max. Uberfahrgeschwindigkeit

bei

Abfrage von Zwischenstellungen kann

ca. 1 m/s. betragen (ohne

Lastvolu-

men).

1st

abhangig

vom Zylinder, den

nachgeschalteten Elementen, den

Schlauchlangen

und dem

Druck

c) Abstand der Schalter

zu

Stahlteilen

15

mm.

d) Der

Anschluf3

@

darf

nicht

geschlos-

sen werden.