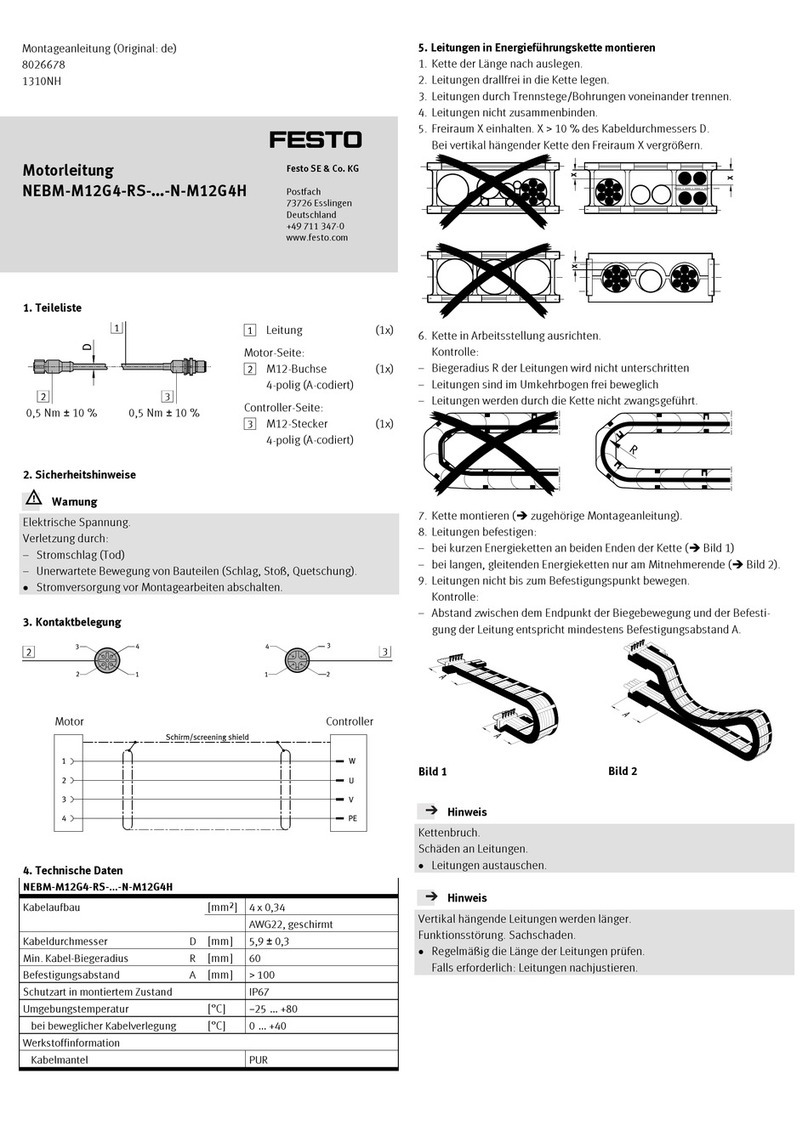

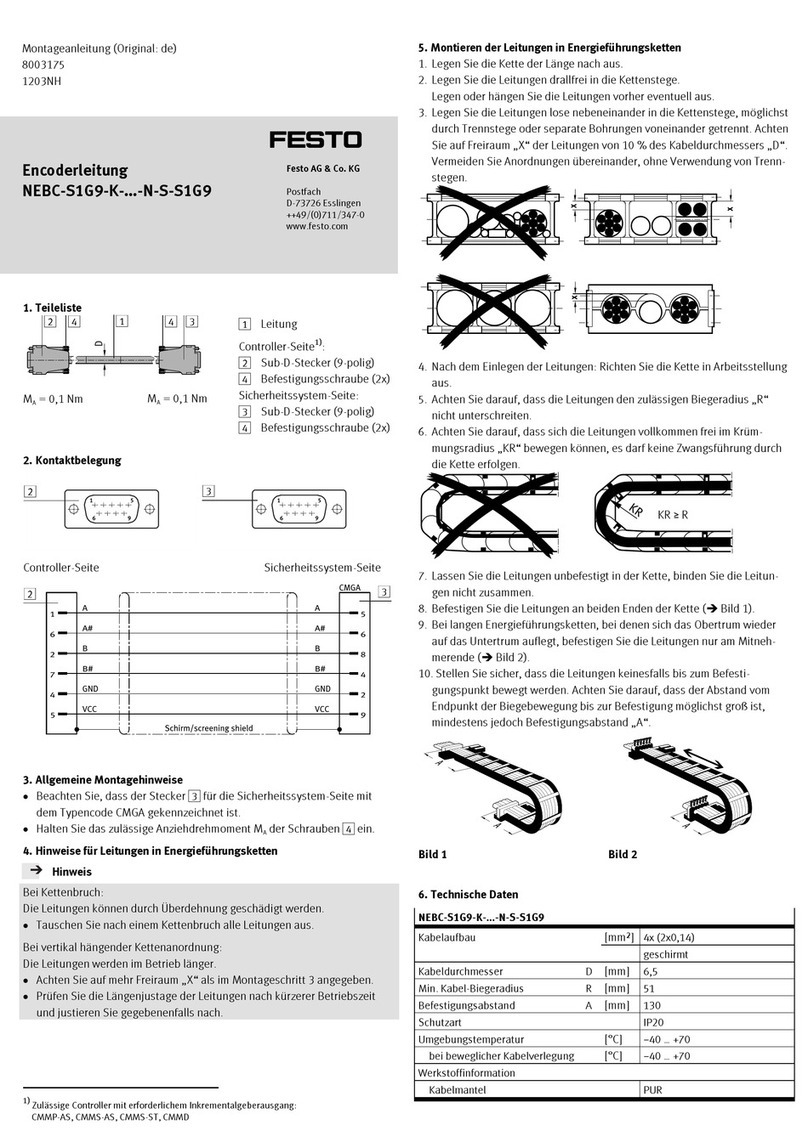

M12 socket, AS-interface Out Pin Allocation

4

23

11AS-interface +

20 V (auxiliary power supply)

3AS-interface –

424 V (auxiliary power supply)

Fig. 3

Note

Electromagnetic interference

• Make the connection to functional earth via the connected device or the elec-

trical connecting plate CAPC-....

Functional test:

– The LED “PS” is illuminated green when the power supply is correctly presented.

– The LED “X1” is lit green if a device is connected and the I-Port communication is

ready to function (chap. 8).

7 Basic settings for fieldbus communication

7.1 Removal of the DIL switch cover

To set the DIL switches, the cover must be removed:

1. Switch off the power supply.

2. Unscrew the two mounting screws of the transparent cover and remove the

cover.

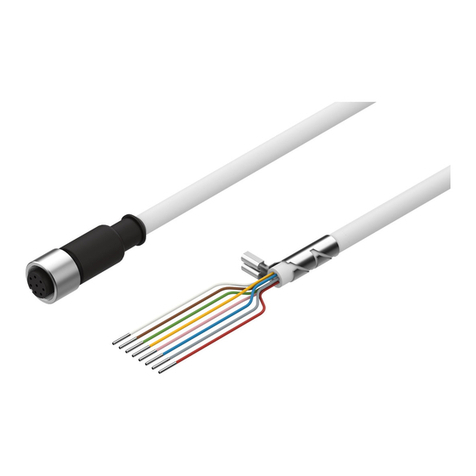

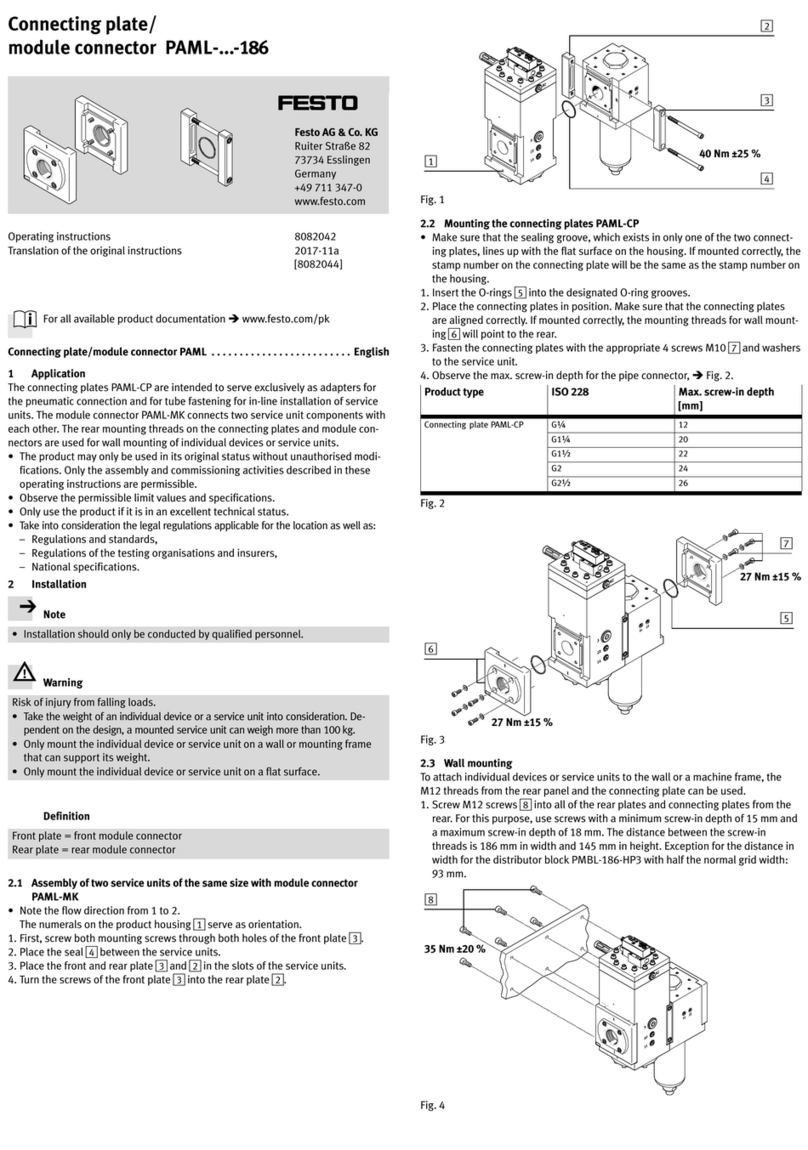

7.2 Setting the DIL switches

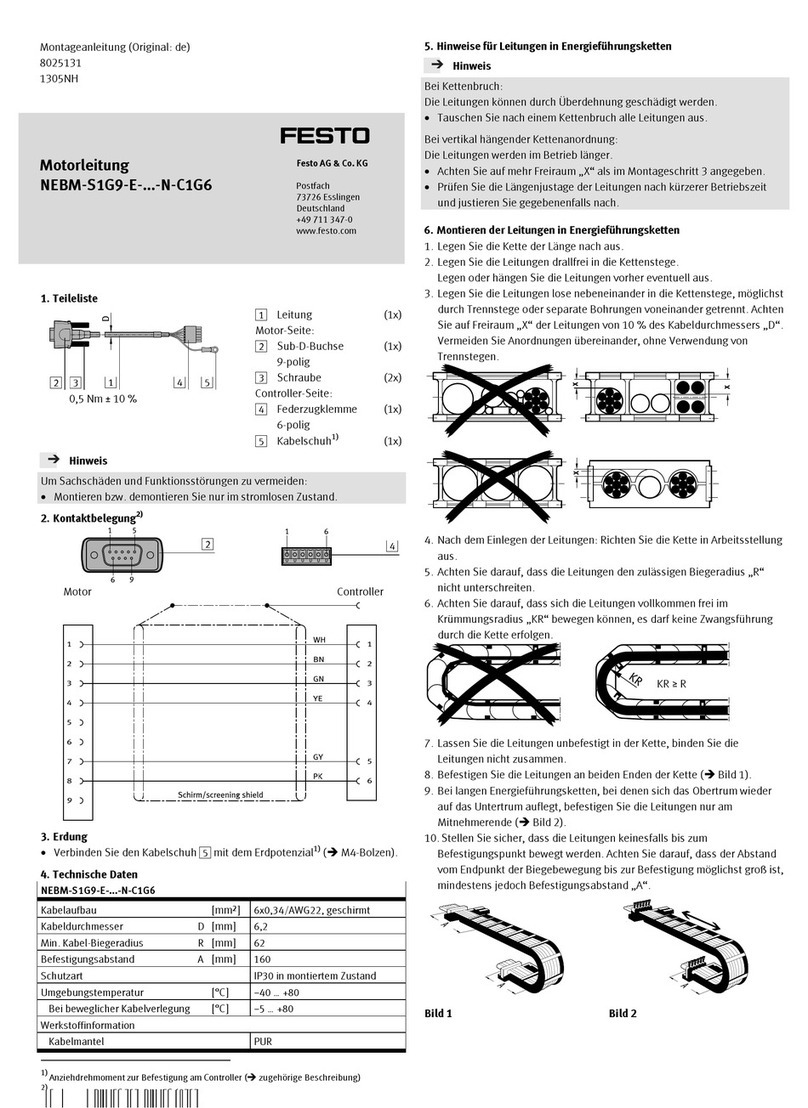

The bus node has a DIL switch group with 2 DIL switches. Set the valve configura-

tion with DIL switches 1 and 2.

1

1DILswitches1and2

Fig. 4

I/O configuration,

AS-interface slaves

Valve configuration DIL

switches

1 2

8I/8O – The first 8 solenoid coils are actuated.

– The number of valves is not checked.

– The profile for both AS-interface slaves is 7.A.7

(factory setting).

OFF OFF

16 I/16 O – The first 16 solenoid coils are actuated.

– The number of valves is not checked.

– The profile for both AS-interface slaves is 7.A.A.

ON OFF

4I/4O – The first 4 solenoid coils are actuated.

– The number of valves is not checked.

– The profile of the AS-interface slave is 7.F.E.

(standard slave).

OFF ON

–Reserved ON ON

Fig. 5

7.3 Mounting of the DIL switch cover

1. Place the cover carefully on the bus node. Make sure that the seal is seated

correctly!

2. Tighten the mounting screws with max. 0.4 Nm with a Torx screwdriver

(size T10) or a slot screwdriver that fits.

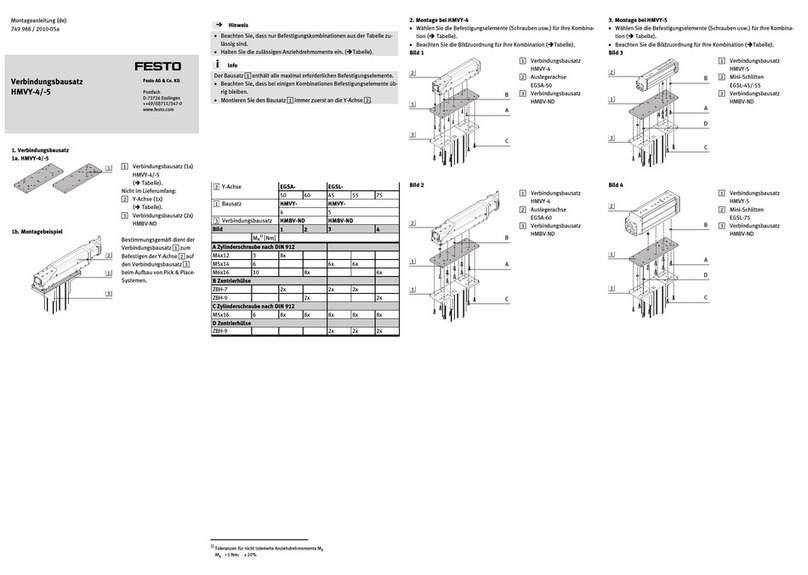

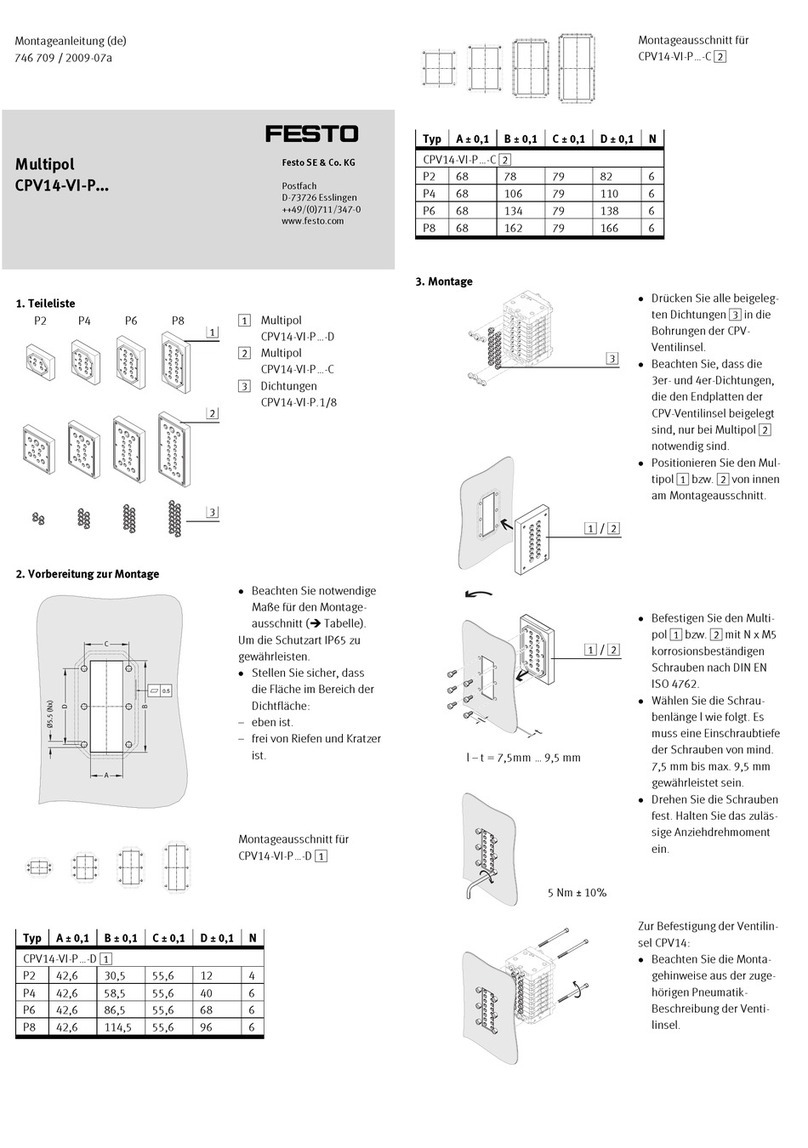

7.4 Address allocation

Before connecting to the AS-Interface bus: Assign a free address to the slave.

Addressing can be performed via an AS-interface addressing device in accordance

C.S.2.1, an addressing cable and through an AS-interface master.

The number of connected solenoid coils is set through the DIL switches

(chap. 7.2). Depending on this setting, the number of slave addresses, IO and

ID code are automatically configured and saved (subsequent table).

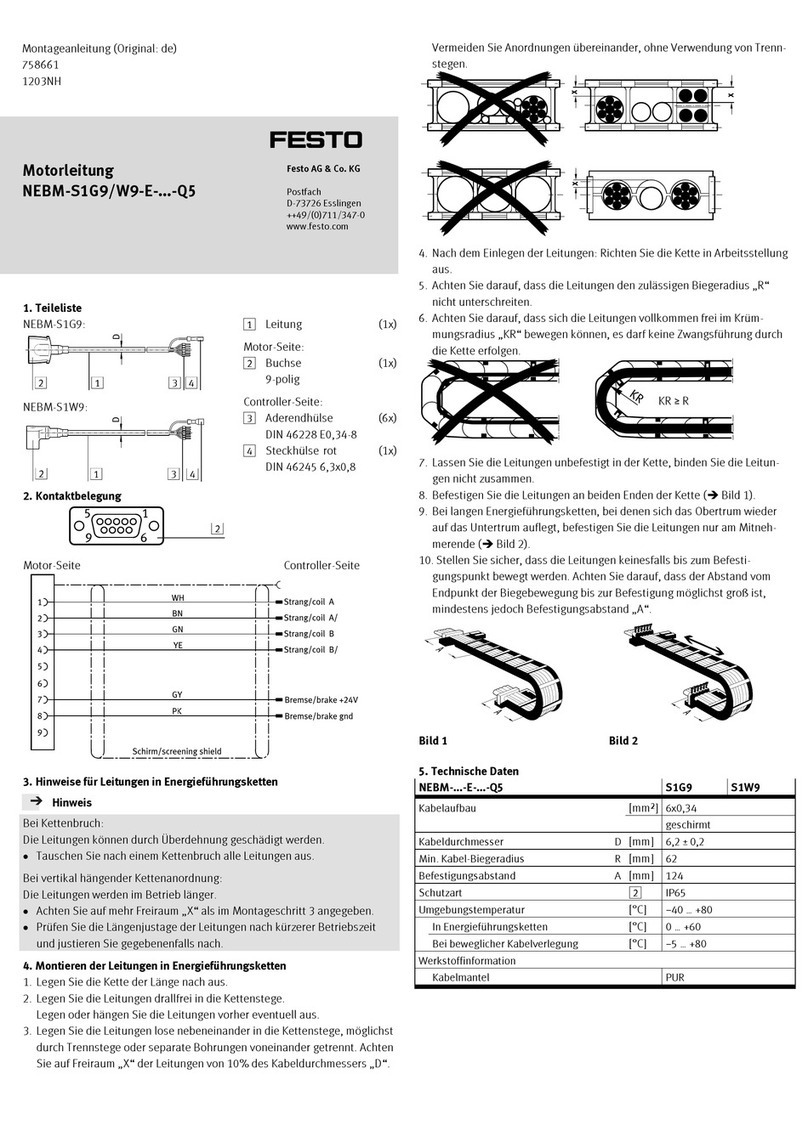

Number of

solenoid coils

Slave

address

Profile 1 Profile 2 AS-interface-

master type

1…4 1Standard S-7.F.E –M1 … M4

1…8 1ExtendedA+B S-7.A.7 S-7.A.7 M4

1…16 1ExtendedA+B S-7.A.A S-7.A.A M4

Fig. 6

Assignment of slave addresses to physical outputs/valves of the connec-

ted devices can be found in the respective product documentation.

8 Status display/diagnostics

8.1 Status display via LEDs

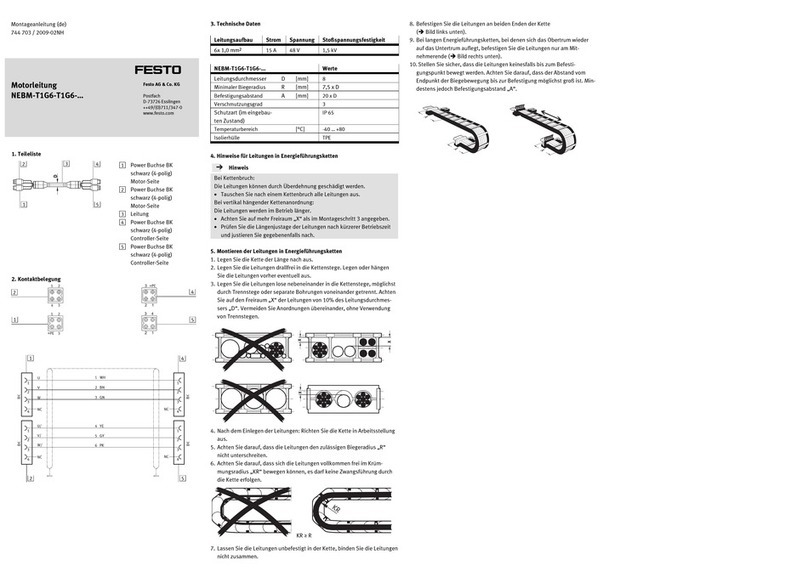

PS (power system) – X1 (I-port)

LED indicator Status and significance

PS X1

Both LEDs light green:

– additional voltage present

LED “PS” lights green, LED “X1” flashes green

– additional voltage present

– short circuit at a solenoid coil or other diagnosis of the I-port device

(peripheral area)

Both LEDs flash green:

– additional voltage missing

LED “PS” lights green, LED “X1” flashes red:

– additional voltage present

– no I-port device detected

– peripheral faults

LED “PS” illuminated green, LED “X1” illuminated red:

– additional voltage present

– short circuit/overload behind the AS-interface coil

– peripheral error, I-port connection interrupted

Fig. 7

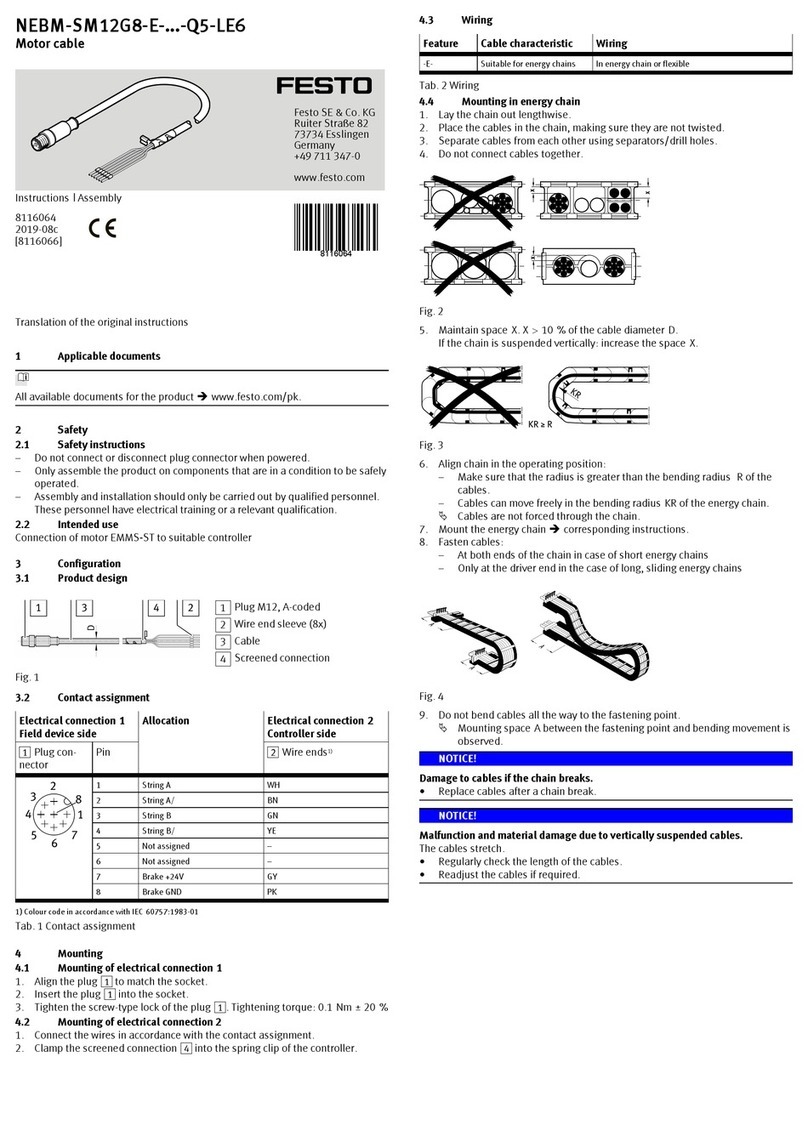

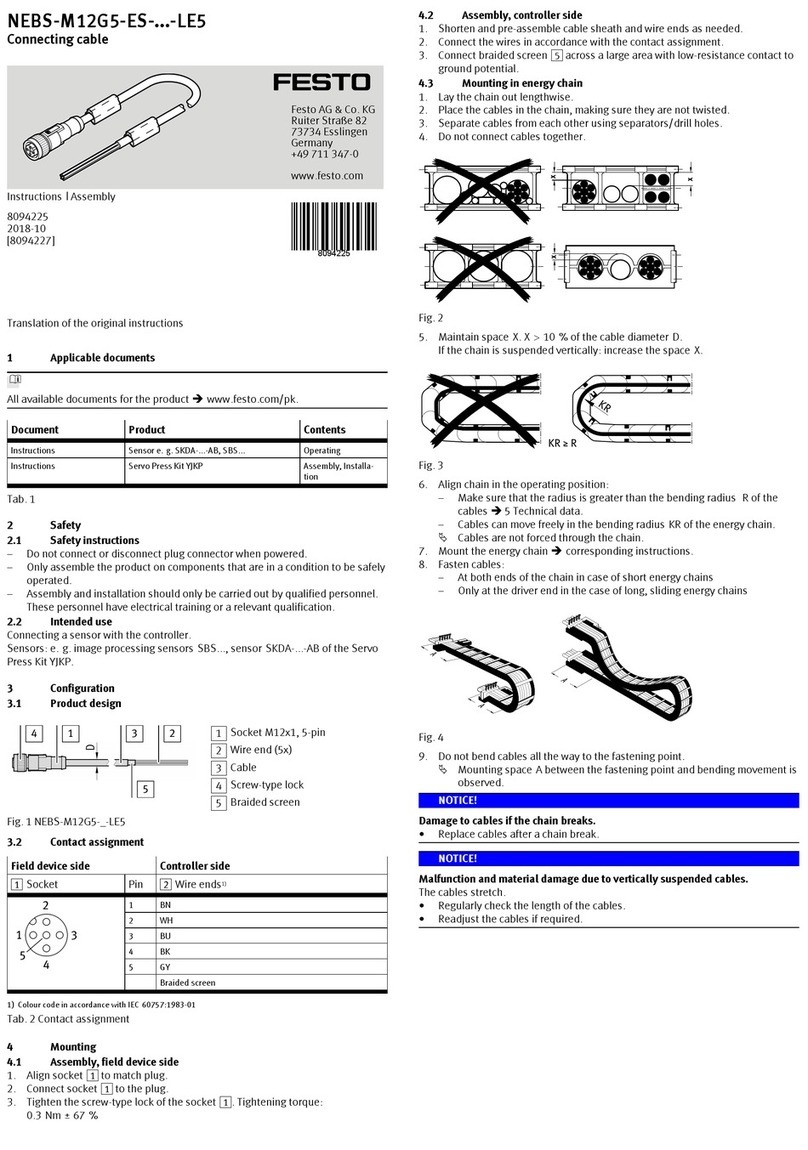

AS-i (AS-interface)

LED

indicator

Status and significance

LED illuminated green:

– AS-interface voltage applied

– no error is present.

LED is off:

– AS-Interface voltage not applied

LED illuminated red:

– AS-interface address not set (equals 0)

– no communication

LED flashes red/green:

– peripheral fault (e.g. no additional voltage, no I-port)

Fig. 8

Note

AS-interface has an integrated watchdog function, which can be activated/deac-

tivated via the parameter bit P0.

Valid is:

–P0=1Watchdog activated (delivery status)

–P0=0Watchdog deactivated

If Watchdog is activated, the outputs are reset as soon as bus communication

malfunctions.

8.2 Error diagnostics via AS-interface bus

AS-interface

parameter-entry bits

Faults

P3 P2 P1 P0

– 1 1 0 short circuit/overload behind the AS-interface coil

– 1 0 1 no additional voltage

– 0 1 1 no I-port device found

– 1 0 0 short circuit at a solenoid coil

Fig. 9