Fig. 5

3. Turn contact holder[B] 180°. Avoid cable twist during turning.

Fig. 6

4. Fasten the contact holder[B] loosely in the previously unused holes[C] with

the two screws[A].

4.5 Wiring

Character

istics

Cable characteristic Wiring

KMP3 Standard Flexible (freely movable, unguided wiring)

The line can be dynamically bent, but not for robots

or energy chains.

KMP4 Suitable for energy chains In energy chain or flexible

Tab. 2 Wiring

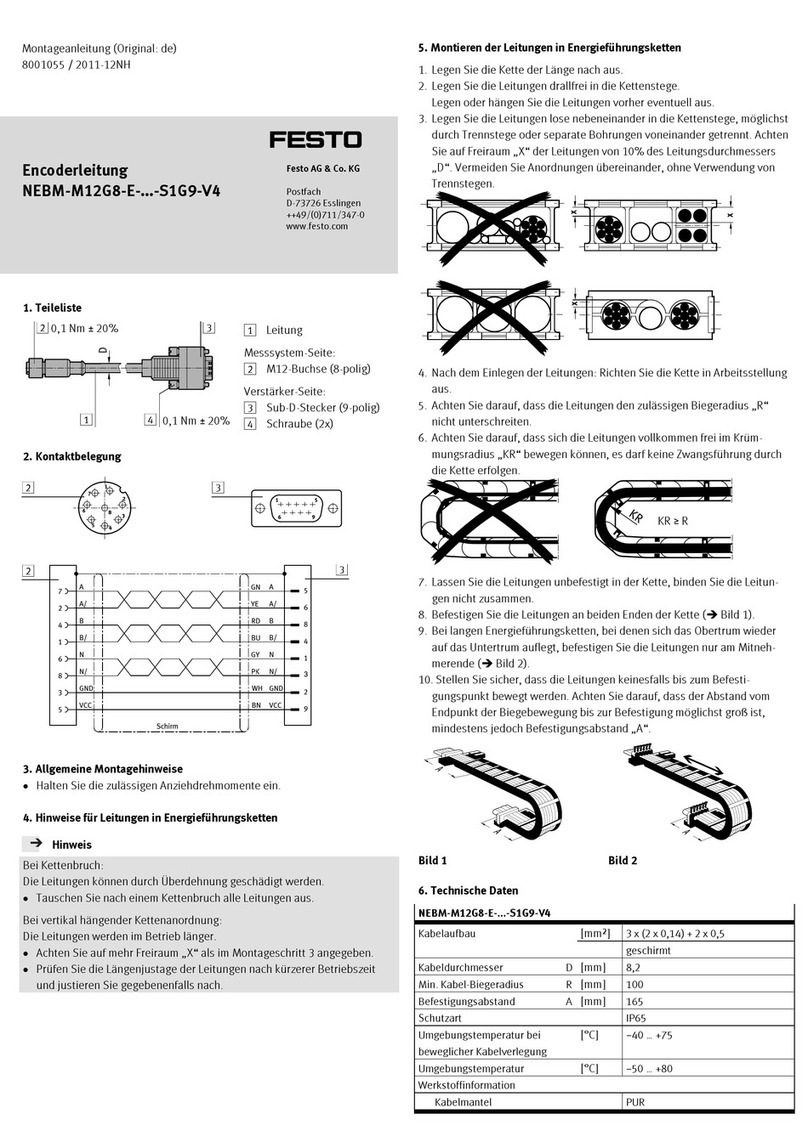

4.6 Mounting in energy chain

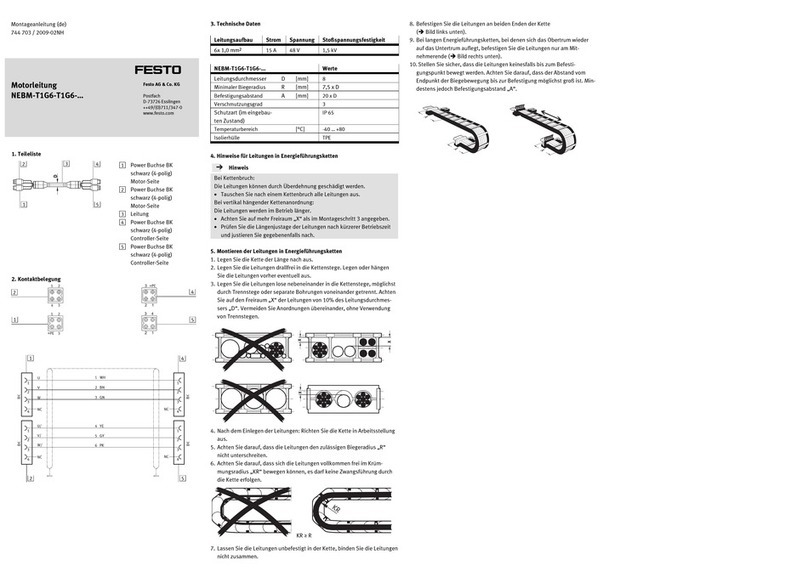

1. Lay the chain out lengthwise.

2. Place the cables on the chain, making sure they are not twisted.

3. Separate cables from each other using separators/drilled holes.

4. Do not connect cables together.

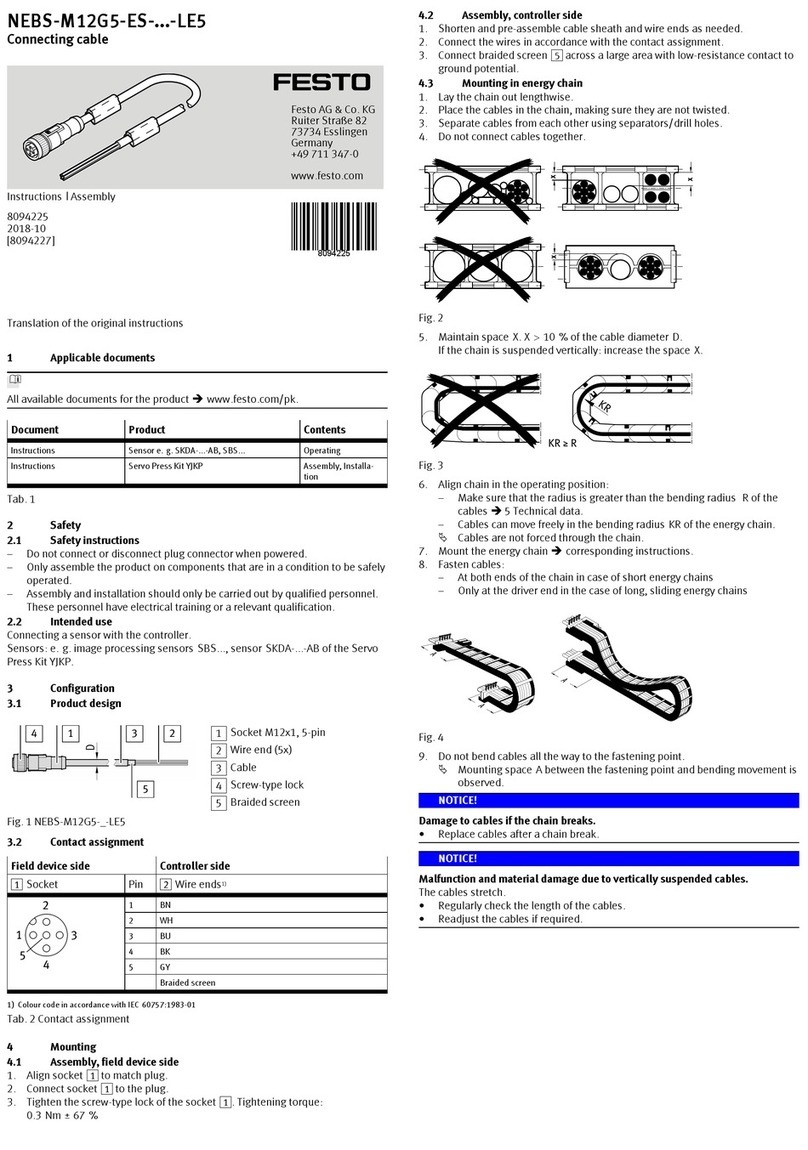

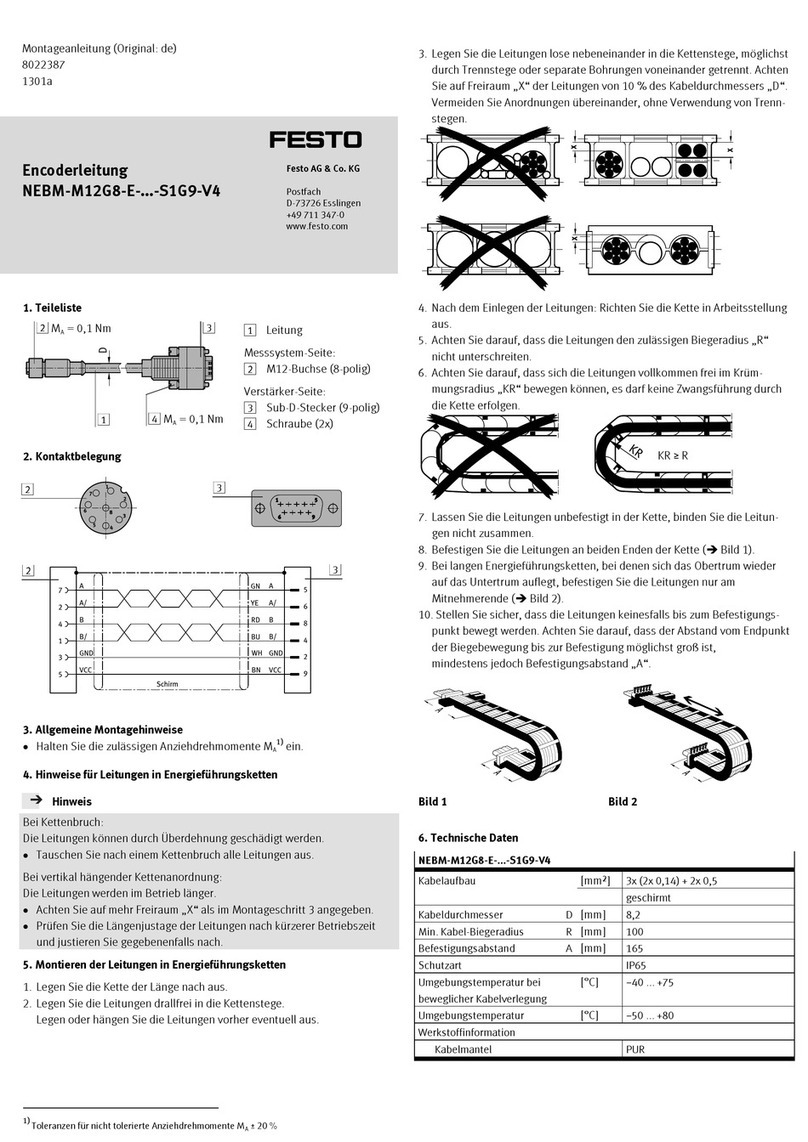

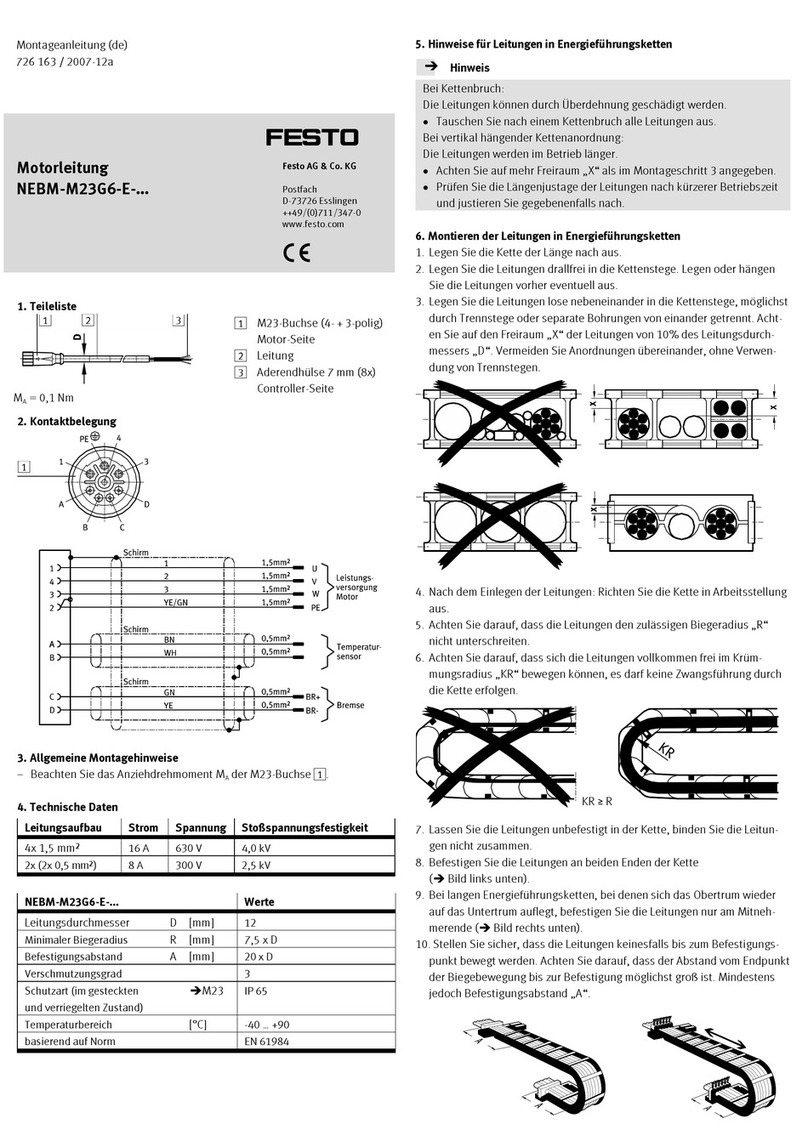

Fig. 7

5. Maintain spaceX. X>10%of the cable diameterD.

If the chain is suspended vertically: increase spaceX.

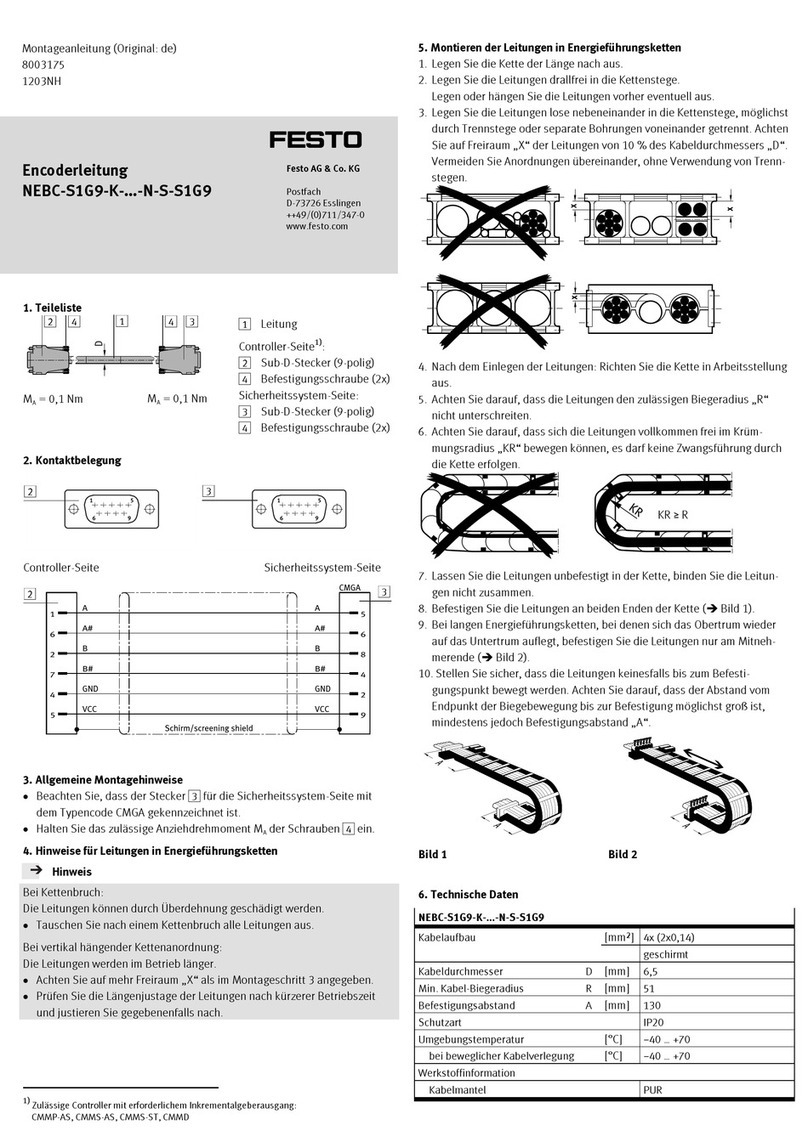

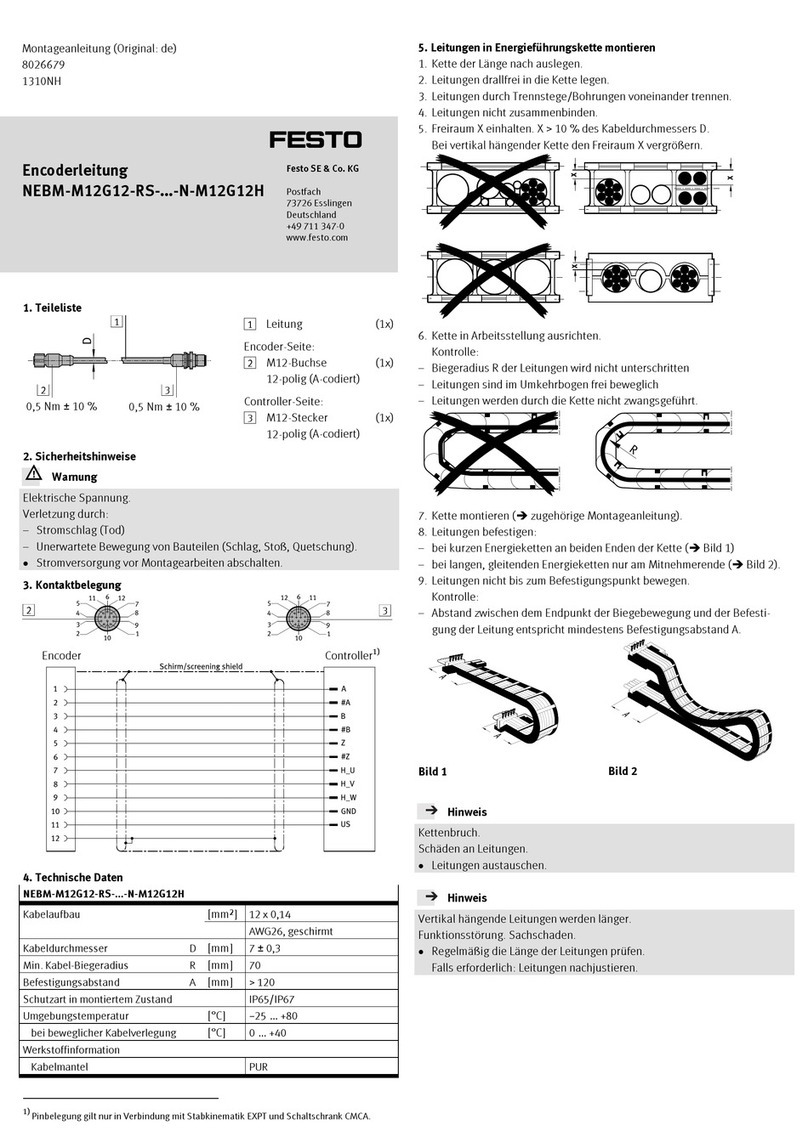

Fig. 8

6. Align chain in the operating position:

– Make sure that the radius is greater than the bending radiusR of the

cables.

– Cables can move freely in the bending radius KR of the energy chain.

ÄCables are not forced through the chain.

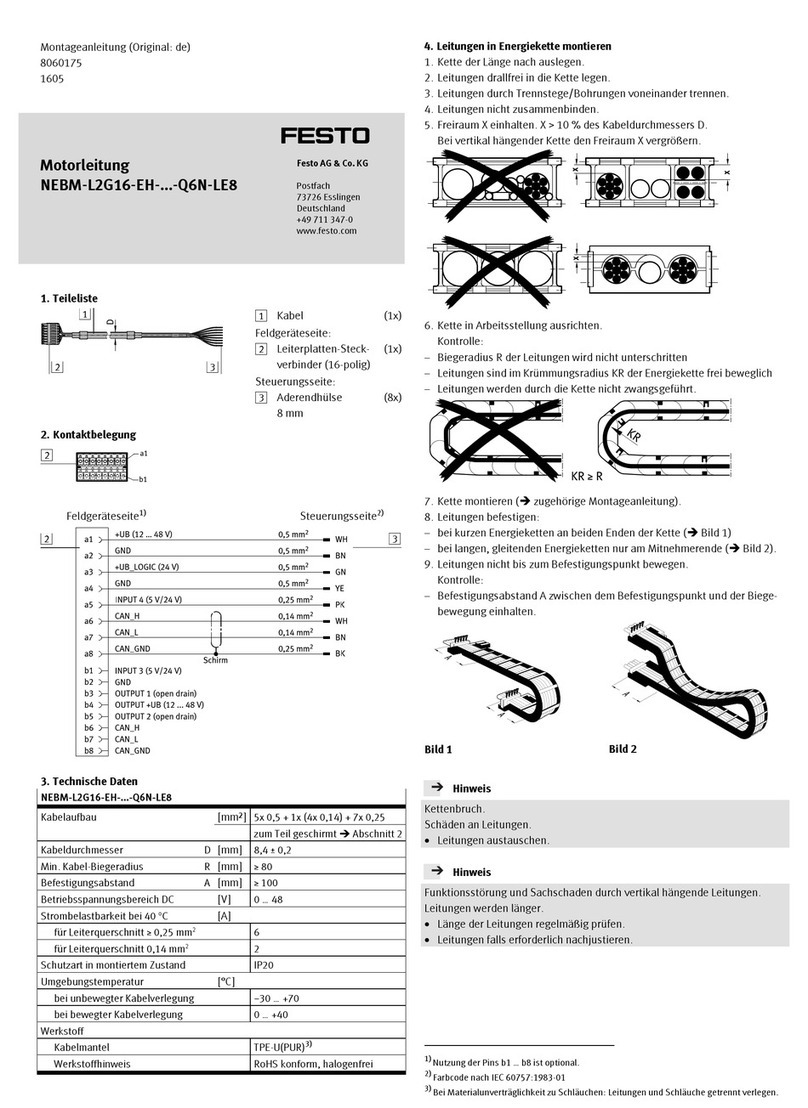

7. Mount the energy chain ècorresponding instructions.

8. Fasten cables:

–with short energy chains (length <1m) at both ends of the chain

–with long sliding energy chains (length >1m) only at the driver end

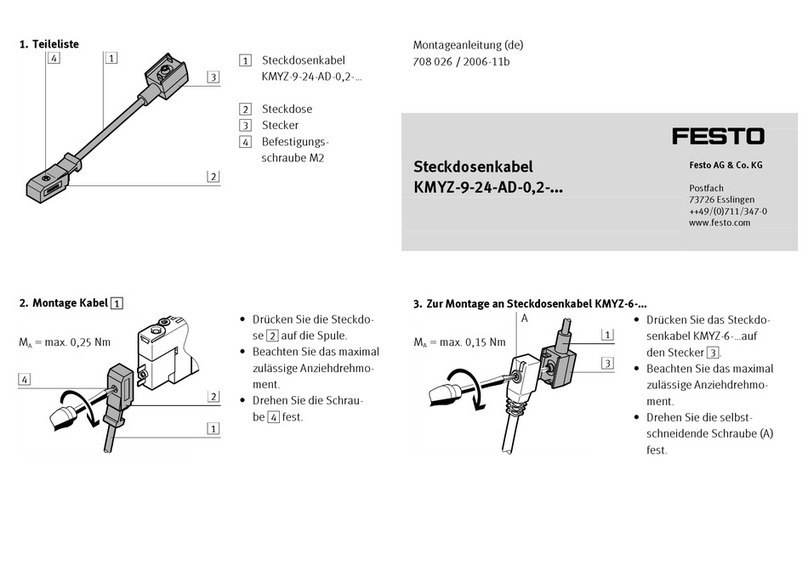

Fig. 9

9. Do not move cables all the way to the fastening point.

ÄMounting spaceA between the fastening point and bending movement is

maintained.

NOTICE!

Damage to cables if the chain breaks.

• Replace cables after a chain break.

NOTICE!

Malfunction and material damage due to vertically suspended cables.

The cables stretch.

• Regularly check the length of the cables.

• Readjust the cables if required.

5 Technical data

KMP... 39P... 325P... 49P... 425P...

Cable characteristic Standard Suitable for energy

chains

Cable composition [mm²] 10x0.34 18x0.34 10x0.25 25x0.25

Cable diameter D [mm] 7.15 8.5 PVC: 7.4

PUR: 7.0

PVC: 10.4

PUR: 9.8

Mounting space A [mm] – PVC:

³148

PUR:

³140

PVC:

³208

PUR:

³196

Current rating at 40°C [A] 3

Surge resistance [kV] 1

Operating voltage range

DC UB[V] 0…30

Bending radius

Fixed cable installation R [mm] ³30 ³45 PVC: ³24

PUR: ³23

PVC: ³33

PUR: ³31

Flexible cable installation R [mm] ³75 ³90 PVC: ³39

PUR: ³37

PVC: ³55

PUR: ³51

Ambient temperature

Fixed cable installation [°C] –25…+70 –40…+70

Flexible cable installation [°C] –5…+70 PVC: –5…+70

PUR: –40…+70

Material

Cable sheath PVC PVC: PVC

PUR: TPE-U(PUR)

Electrical connection1

Function Field device side

Connection type Socket

Connection technology Sub-D

Type of mounting 2x M3 screw

Electrical connection2

Function Controller side

Connection type Cable

Connection technology Open end

Wire ends Cut off bluntly

Tab. 3 Technical data