– The product is assembled.

– The contact surfaces must be clean (avoid leakage and contact errors).

• Connect pneumatic connections 1, 2.

7.2 Electrical installation

WARNING!

Risk of injury due to electric shock.

• For the electrical power supply, use only PELV circuits in accordance with IEC

60204-1/EN 60204-1 (Protective Extra-Low Voltage, PELV).

• Observe the general requirements of IEC 60204-1/EN60204-1 for PELV cir-

cuits.

• Only use voltage sources that ensure a reliable electric separation from the

mains network in accordance with IEC 60204-1/EN 60204-1.

For the MSE6-C2M…-M with CPX-Extension series 1 connection, the following

applies:

NOTICE!

Material damage as a result of changing the connecting cable when the supply

voltage is switched on

• Connect and remove the CPX-Extension connecting cable only when the sup-

ply voltage is switched off for the control extension series 1 device.

• Only use pre-assembled connecting cables.

1. Connect the earth terminal.

2. Connect CPX-Extension connecting cable (only for MSE6-C2M…-M)

è 5.1.3 Connecting components.

3. Connect power supply and electrical inputs and outputs.

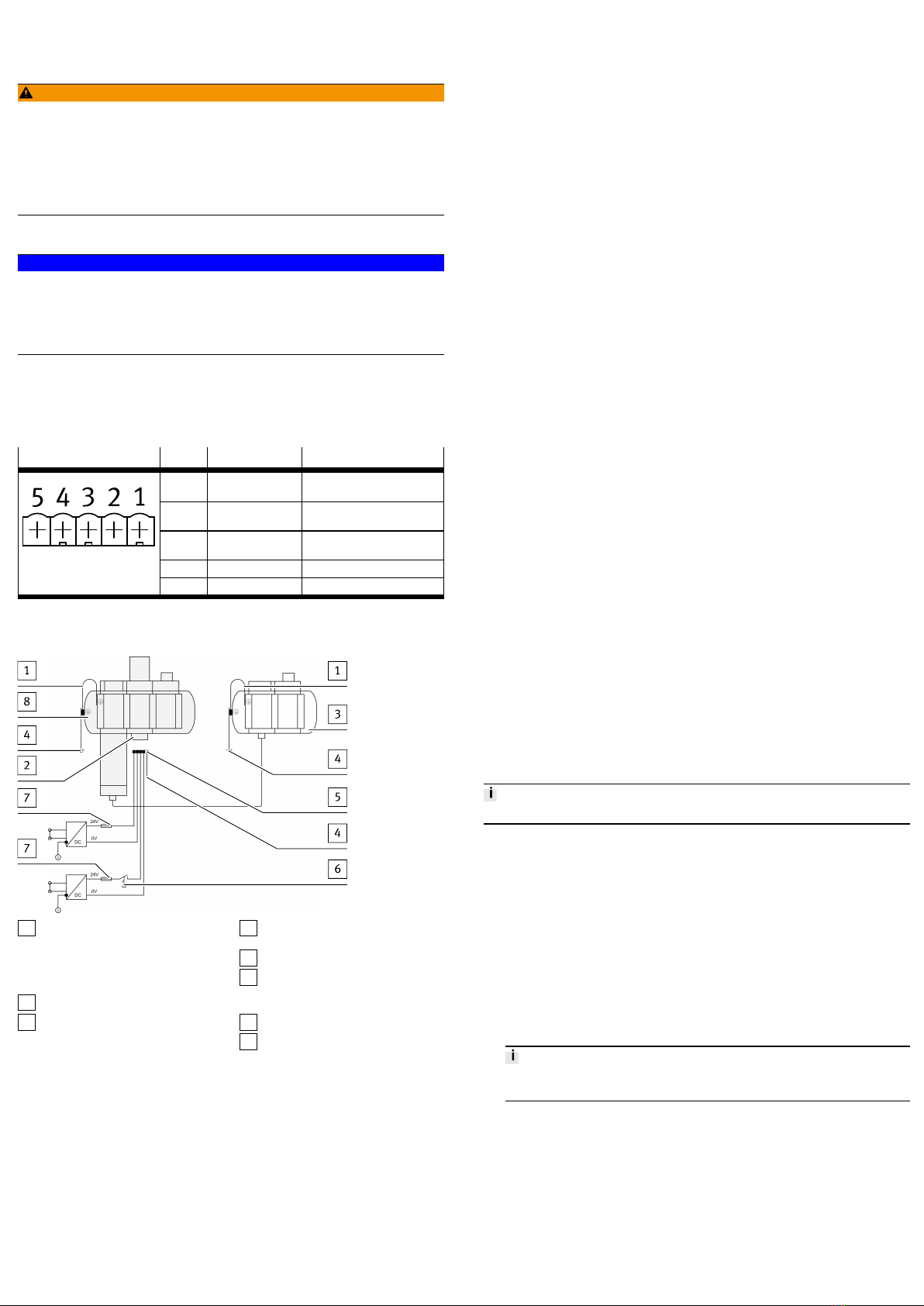

Pin allocation

Plug Pin System supply Function

1 24V DC UEL/SEN Operating voltage supply for

the electronics and sensors

2 0V UEL/SEN Operating voltage of electronics

and sensors

3 24V DC UOUT/A Load voltage supply for actuat-

ors

4 0V UOUT/A Load voltage of actuators

AIDA Push-pull

5 FE Functional earth

Tab. 6 Pin allocation, system supply

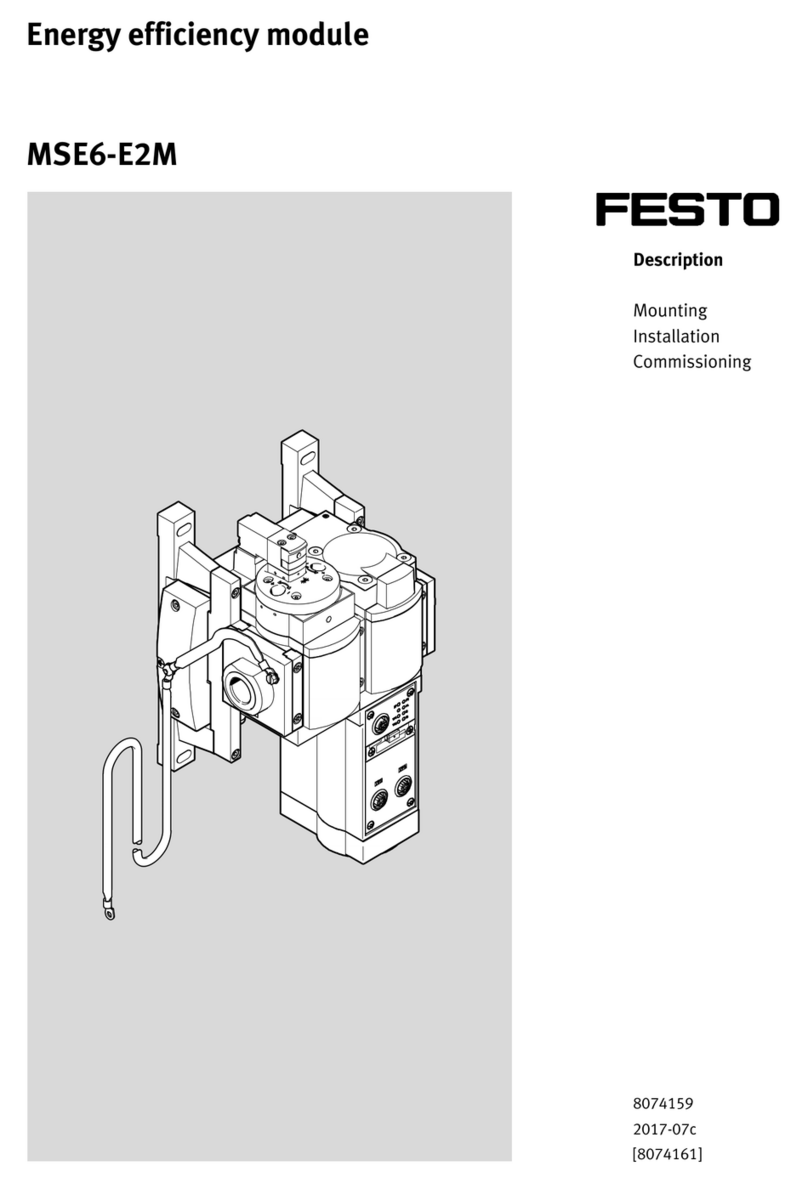

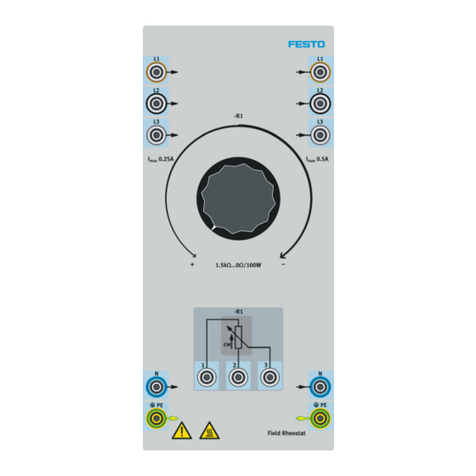

Electrical connection example

1Equipotential bonding between

the earth terminal of the left-hand

pneumatic sub-base and the left

end plate of the electrical interlink-

ing module

2System supply

3MSE6-D2M

4Equipotential bonding of function-

al earth (FE)

5Earth terminal pin 5

6Power supply can be separately

disconnected for actuator techno-

logy and electrical inputs

7External fuses

8MSE6-C2M …-M

Fig. 4 Power supply with separate circuits and equipotential bonding

7.3 Combination with MS6 modules

General information

– Maximum permissible number of entire service unit component combina-

tion:10individual modules. The product MSE6-C2M counts as a triple module

here.

– When supplementing MS6 modules, only use the wall mounting MS6-WPG

and the module connector MS6-MV-EX.

– When supplementing MS6 modules, the screws on the module connector

between the flow sensor, proportional-pressure regulator and the shut-off

valve may not be loosened èRestriction of EMC immunity to interference.

– Observe the assembly instructions for the wall mounting-SET MS6-WPG.

– In the case of a larger device configuration, a longer FE joint is required.

– The cable has a nominal cross section of 5mm2 with cable lug in accord-

ance with DIN 46234-4-6.

– Alternatively: earthing straps are manufactured in a bare or tin-plated

design in accordance with DIN 46444 or in accordance with DIN 72333-3.

Nominal cross section: >5mm2. Connection: M4.

Assembly

1. For pre-assembled MS6 combinations: replace the wall brackets with a

MS6-WPG wall mounting-SET.

2. For MS6 individual modules: replace module connectors for pre-assembled

MS6 combinations with MS6-MV-EX module connectors.

3. For additions to the left side: remove the left-hand pneumatic sub-base of the

MS6 module or MS6 module combination. At this point, assemble the left

pneumatic sub-base of the product.

4. For additions to the right side: remove the right-hand pneumatic sub-base of

the MS6 module or MS6 module combination. At this point, assemble the

right pneumatic sub-base of the product.

Earth terminal

1. Connect the earth terminal on the pneumatic sub-base with low impedance

(short cable with large cross-sectional area) to the end plate of the electrical

linkage module of the product (pre-assembled on delivery status)

è 7.2 Electrical installation.

2. Ensure that the earth terminal at the left end plate of the electrical interlink-

ing module on the product and the earth terminal at the power supply con-

nection have the same potential and that there are no compensating currents.

3. If necessary, the pre-assembled electrical joint of the energy efficiency mod-

ule MSE6-C2M must be replaced by a longer, electrically equivalent joint.

8 Commissioning

8.1 Safety

The product is equipped with a pneumatically-piloted proportional-pressure regu-

lator and a downstream shut-off valve. The shut-off valve is pneumatically piloted

and is open in a normal position. When inlet pressure P1 is applied, the product

automatically regulates the outlet pressure in the following cases to the last para-

meterised power-on target pressure (default setting 10 bar):

– Switch on of operating voltage until the connection is successfully made with

the high-order controller.

– Interruption of the network communication with correspondingly set system

parameters

– Stopping of the higher-order controller (see manufacturer's specifications),

e.g. in the case of transmission of control programs, parameters, configura-

tion data.

In the event of undervoltage in the operating voltage or the load voltage, the elec-

tronic pressure regulation is inactive when the shut-off valve is open. If pro-

longed, this can lead to an undefined drop in the outlet pressure.

8.2 Commissioning the product

The MSE6-C2M…-M enables the connection of an MSE6-D2M or max. 3 CPX I/O

modules in CPX-Extension series 2.

CPX-Extension connection and connectable CPX I/O modules

è 12.3 Technical data, electrical.

The product is delivered with pre-set parameters.

1. Check pneumatic tubing connection.

2. Check earth terminal.

3. Check the electrical wiring.

4. Check settings of the DIL switches.

5. Switch on the power supply for the product and the high-order controller.

6. Call up the control software.

7. Download the network-specific device description file from Festo's support

portal (GSDML file) èwww.festo.com/sp.

8. Import the device description file into the controller.

9. Activate the network scanner or open the hardware catalogue.

10. Transfer the product and bus node and the connected I/O modules for the

MSE6-C2M…-M from the hardware catalogue into the software controller

(detailed information can be found in the documentation for the higher-order

controller).

The module number 0 is always automatically assigned to the function mod-

ule and the module number 1 to the integrated bus node.

11. Configure the product (e.g. make settings for network interfaces).

12. Parameterise the product (e.g. upper flow rate critical limit).

13. Apply compressed air to the product.

ÄThe product is operational with pre-set parameters.

Upon successful commissioning, the LED P is dark. The LED P2 illumin-

ates if the pressure at the pneumatic connection P2 is > or = 4bar (pre-

set parameter value). With bus node CPX-M-FB34, the LEDs PS and PL

light up green. The LEDs TP1 and TP2 light up when the respective port is

used. The remaining LEDs do not light up.