3 Requirements for product use

• Make these operating instructions available to the design engineer and installer

of the machine or system in which this product will be used.

• Keep these operating instructions during the entire product life cycle.

• Observe the rules/information of the trade association, the VDE specifications

and relevant national regulations at the location of use.

3.1 Technical requirements

General conditions for the correct and safe use of the product, which must be

observed at all times:

• Maintain the specified limits (e.g. for pressures, temperatures and electric

voltages).

• Make sure there is a supply of correctly prepared compressed air in accordance

with the specifications on the medium.

• Before mounting, remove particles in the supply lines through appropriate

measures. In this way, you protect the product from premature failure and high-

er wear.

• Pressurize your entire system slowly. This allows avoidance of abrupt move-

ments.

• Observe the warnings and instructions in these operating instructions.

• Use the product in its original state, without any unauthorised product modifica-

tions.

3.2 Qualification of trained personnel

Installation, mounting, commissioning, maintenance, repair and removal from

operation may only be performed by qualified personnel with knowledge and ex-

perience with electrical and pneumatic control technology.

3.3 Range of application and certifications

The products MS9-SV-...-C-V110-... and MS9-SV-...-C-V230-... fulfil requirements of

EC directives and are equipped with the CE marking.

Standards and test values, which the product must comply with and fulfil, can be

found in the section “Technical data”. The product-relevant EC directives can be

obtained from the declaration of conformity in the internet.

www.festo.com

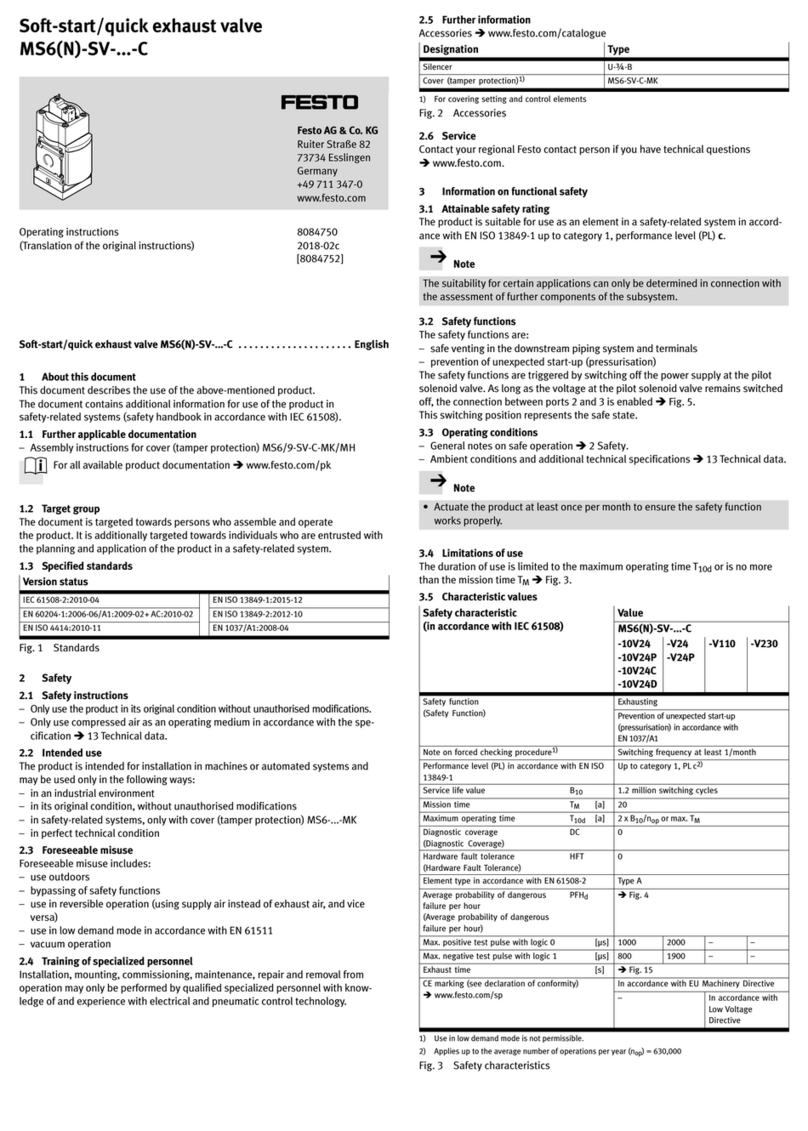

3.4 Standards

Standard Title

EN ISO 13849-1:2008-06 Safety of machinery - safety-related parts of control systems

Part 1: General principles for design

EN ISO 13849-2:2008-06 Safety of machinery - safety-related parts of control systems

Part 2: Validation

EN 60204-1:2006-06 Safety of machinery - electrical equipment of machines

Part 1: General requirements

EN ISO 4414:2010-11 Fluid engineering - general rules and safety-related requirements

for pneumatic systems and their components

Fig. 4 Standards

3.5 Service

Please consult your local Festo repair service if you have any technical problems.

4 Mounting and installation

4.1 Mechanical

Note

Information about mounting of module connectors, sub-bases and mounting

brackets can be found in the operating instructions enclosed with the relevant

accessories.

• Place the MS9-SV-...-C as close as

possible to the location of use.

• Place the MS9-SV-...-C in such a way

that you have sufficient space for a

silencer.

• The mounting orientation is any de-

sired.

• Observe the flow direction from 1 to

2. Serving as orientation are the nu-

merals 1on the product housing.

Fig. 5 Flow direction

1

Combination with service units of the MS series

1. Place the module connectors

MS9-MV 2in the grooves of the in-

dividual devices. A seal 1is re-

quired between the individual

devices.

2. Fasten the module connectors

MS9-MV with 2 screws.

Fig. 6 Assembly

max. 8 Nm

1

2

4.2 Pneumatic

Port 1 and 2

If using fittings:

• Observe the maximum permissible screw-in depth of the connecting threads:

ISO 228 NPT

MS9-…-¾/1: 18.5 mm MS9-…-N¾/N1: 18.5 mm

MS9-…-AGD/AGE/AGF: 18.5 mm MS9-…-AQR/AQS/AQT: 18.5 mm

MS9-…-AGG/AGH: 31.5 mm MS9-…-AQU/AQV: 31.5 mm

Fig. 7 Max. screw-in depth

• Make sure that the compressed air lines are connected correctly.

• Screw the connectors into the pneumatic ports using suitable sealing material.

Port 3 (thread size G1 or NPT1)

When exhausting a system through the MS9-SV-...-C, high sound pressure levels

are generated. We therefore recommend that you use a silencer.

Note

The silencer listed in the accessories U-1-B can be retrofitted on replaced only on

equipment with metric threads.

When retrofitting the silencer on a device with NPT thread at port 3, the cover of

the MS9-SV-...-C can be destroyed. When retrofitting, an adequate silencer with

NPT thread must be used.

• Screw the silencer into the pneumatic port 3.

• Make sure that there is unrestricted exhausting. Neither the silencer nor port 3

should be blocked.

5 Electrical connection

Warning

Electrical connections should be established only in the absence of voltage and

by qualified personnel.

Warning

Use only power sources which guarantee reliable electrical isolation of the oper-

ating voltage in accordance with IEC/EN 60204-1. Consider also the general

requirements for PELV circuits in accordance with IEC/EN 60204-1.

Note

Long signal lines reduce the resistance to interference.

• Make sure that the signal cables are not longer than 20 m.