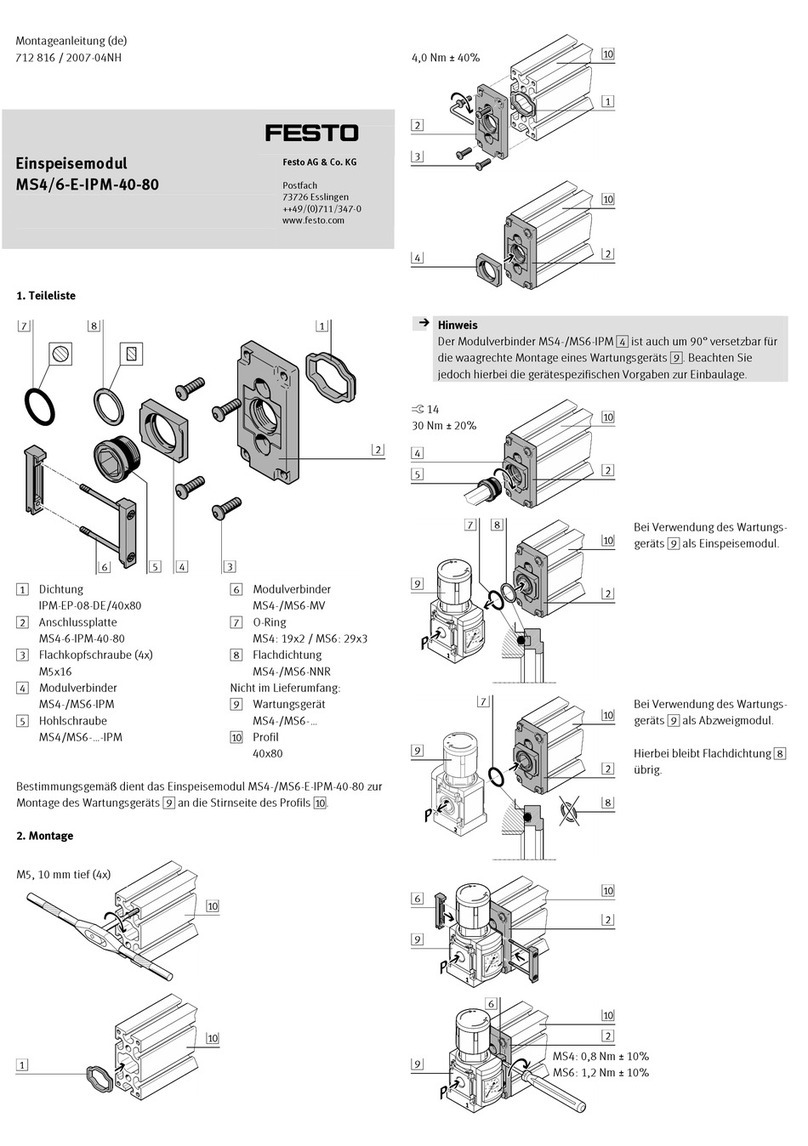

Angle seat valve with diaphragm actuator

VZXA-...-M

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Instructions | Operating

(Translation of the original instructions)

8082926

2018-02a

[8082928]

Angle seat valve with diaphragm actuator VZXA-...-M English................

1 About this document

This document describes the use of the above-mentioned product. It contains

additional information for the implementation of the product in safety-oriented

systems (safety handbook in accordance with IEC 61508).

For all available product documentation èwww.festo.com/pk

1.1 Specified standards

Version status

IEC 61508-1:2010 part 1, 2, 4…7 IEC 61511:2016

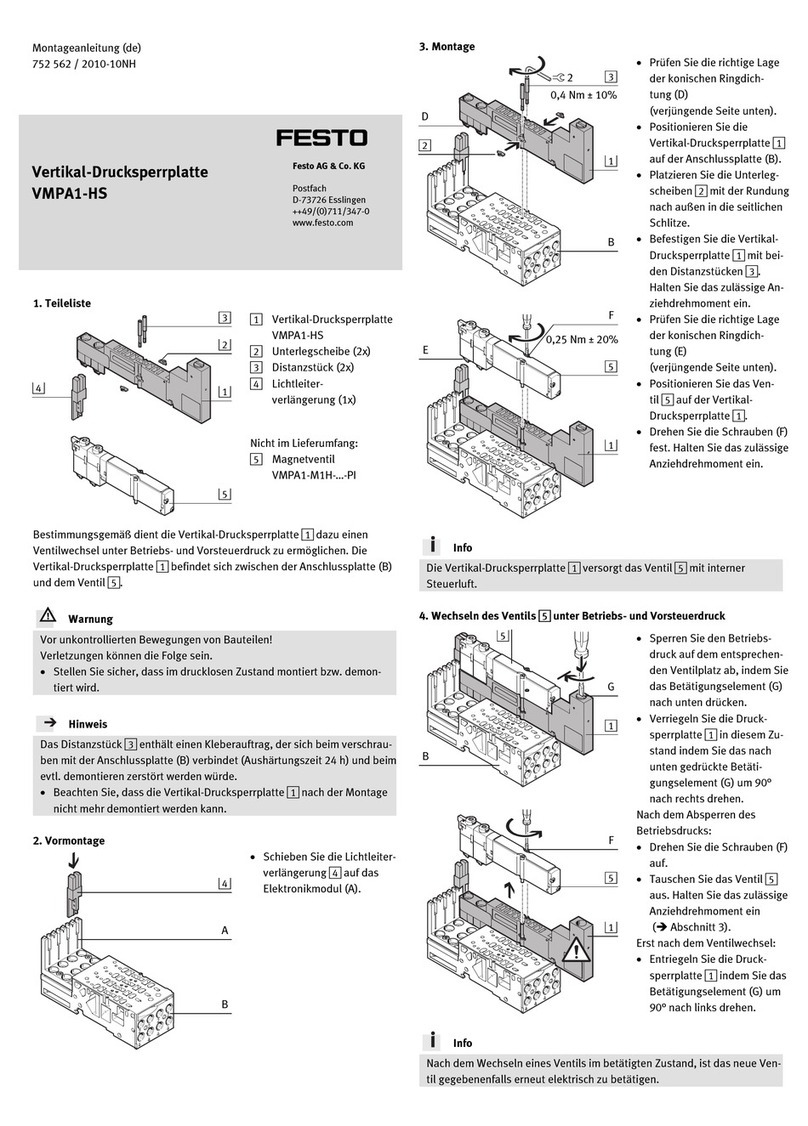

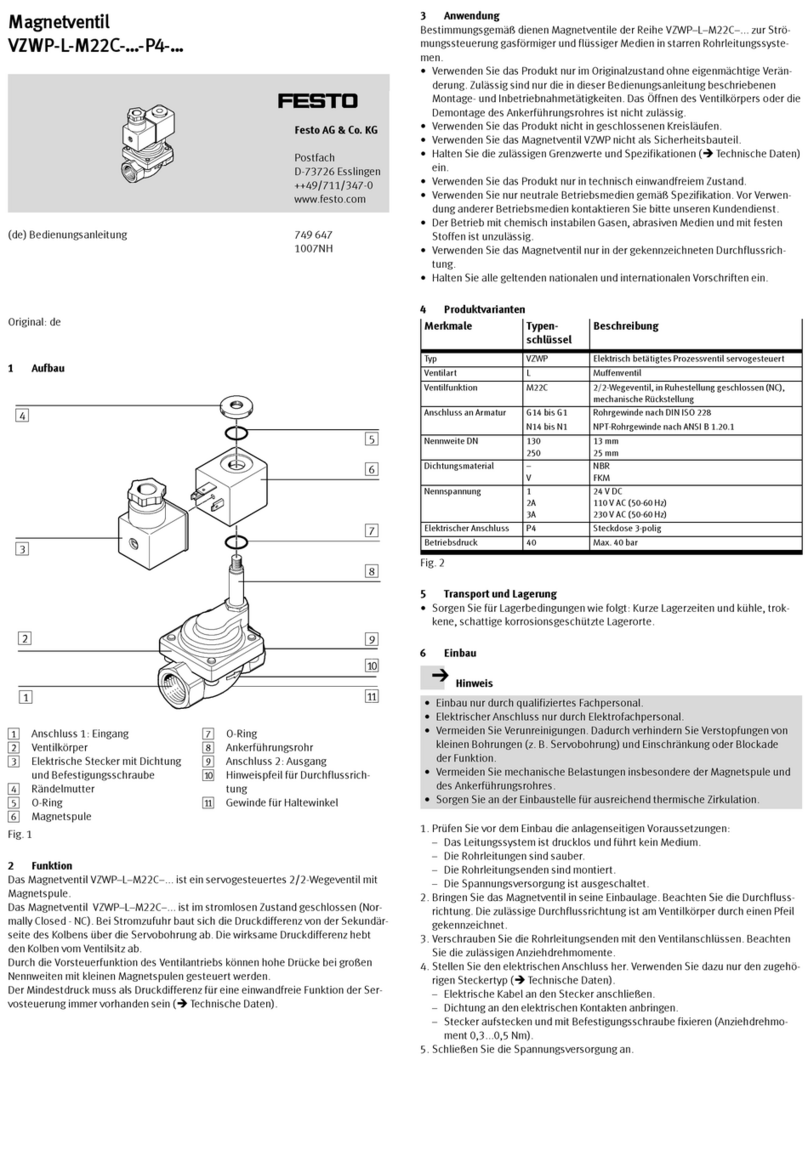

Fig. 1

2 Safety

2.1 General safety information

The product may only be used in its original status without unauthorized modi

fications.

Use the valve only in the flow direction indicated.

Only use the product if it is in perfect technical condition.

Take into consideration the ambient conditions at the location of use.

Media

Only use media in accordance with specifications èTechnical data.

Use only media that will not cause dangerous reactions if mixed.

Do not operate the product with chemically unstable gases, abrasive media

or solid materials.

If water is used: up to approx. 1000 ppm of chloride content is permitted.

Avoid tensile stresses.

If aggressive media are used: limit medium temperature to 65 °C.

Actuator

Do not open the actuator (pressure in the actuator or loaded spring).

Avoid mechanical stresses on the valve. Do not use the actuator as a lever.

Return to Festo

Hazardous substances can endanger the health and safety of personnel and cause

damage to the environment. To prevent hazards, the product should only be re

turned upon explicit request by Festo.

Consult your regional Festo contact.

Complete the declaration of contamination and attach it to the outside of the

packaging.

Comply with all legal requirements for handling hazardous substances and

transporting dangerous goods.

2.2 Intended use

The angle seat valve VZXA-...-M is intended to shut-off gaseous or liquid media in

piping systems.

To control liquid media, use only the product variant VZXA-B... (media flow under

valve seat).

2.3 Training of specialized personnel

Work on the product should only be conducted by qualified personnel. The quali

fied personnel must be familiar with installation of process automation systems.

3 Further information

– Accessories èwww.festo.com/catalogue

– Spare parts èwww.festo.com/spareparts

4 Service

Contact the regional Festo contact if you have technical questions

èwww.festo.com.

5 Information on functional safety

5.1 Attainable safety rating

The product is suitable for use as an element in a safety-related system in accord

ance with IEC 61511.

– In low-demand mode up to SIL 2

– In high-demand mode up to SIL 2.

Taking into account the necessary minimum hardware fault tolerance from HFT = 1,

the product can also be used up to SIL 3 with a redundant design of the entire system.

Note

The suitability for certain applications can only be determined in connection with

the evaluation of further components of the subsystem.

5.2 Safety function

Single-acting valves

The safety function consists of taking the initial position on request. The request is

made by removing the operating pressure.

– Valves with control function NO: The valve opens completely and remains open

until operating pressure is applied.

– Valves with control function NC: The valve closes completely and remains closed

until operating pressure is applied.

Double-acting valves

The safety function consists of taking the desired position on request. Supply of

external energy is required for this.

5.3 Operating conditions

– General notes on safe operation èChapter 2.

– Periodic tests (performance test) èChapter 12.

– Ambient conditions and additional technical specifications èChapter 16.

5.4 Limitations of application

The service life is not limited if the operating conditions are complied with.

– Maximum admissible interval for a complete performance test: seven years.

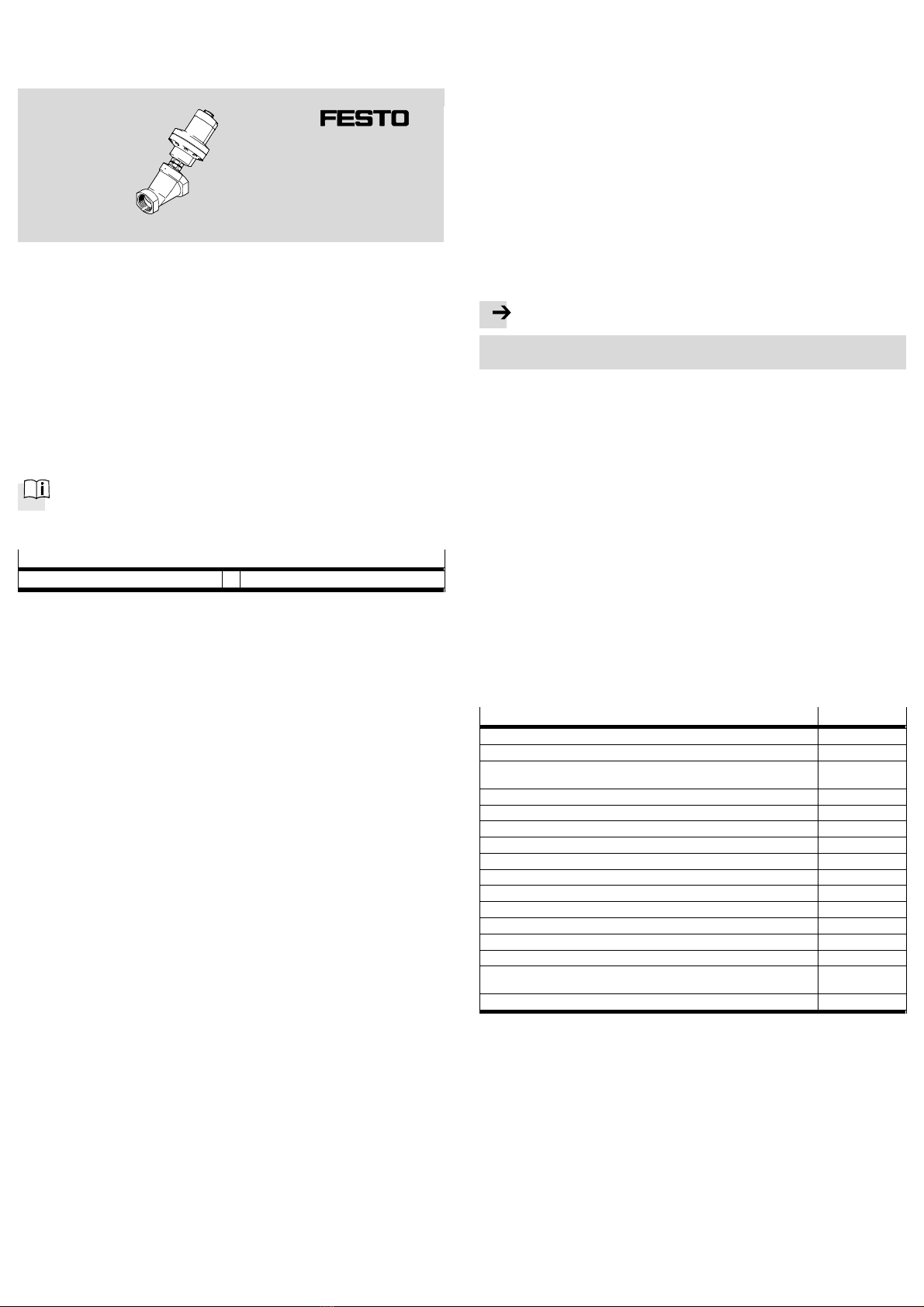

5.5 Characteristic values

Safety standards (in accordance with IEC 61508) Value

Route of assessment 2H/ 1S

Type of Sub System Type A

Mode of Operation Low Demand and

High Demand

Assumed Test Interval Ti1 a

Confidence Level 1-á95 %

Hardware Fault Tolerance HFT 0

Lambda Dangerous ëD1,36 · 10-7 / h

Lambda Dangerous Undetected ëDU 1,36 · 10-7 /h

Mean Time To Dangerous Failure MTTFD7,37 . 106h

Proof Test Coverage PTC 95 %

Low Demand Mode

Assumed Demands per Year nop 1 / a

Average Probability of Failure on Demand PFDavg 5,95 · 10-4

High Demand Mode

Assumed Demands per Year nop 1 / h

(8760 / a)

Probability of dangerous Failure per Hour PFH 1,36 · 10-7 / h

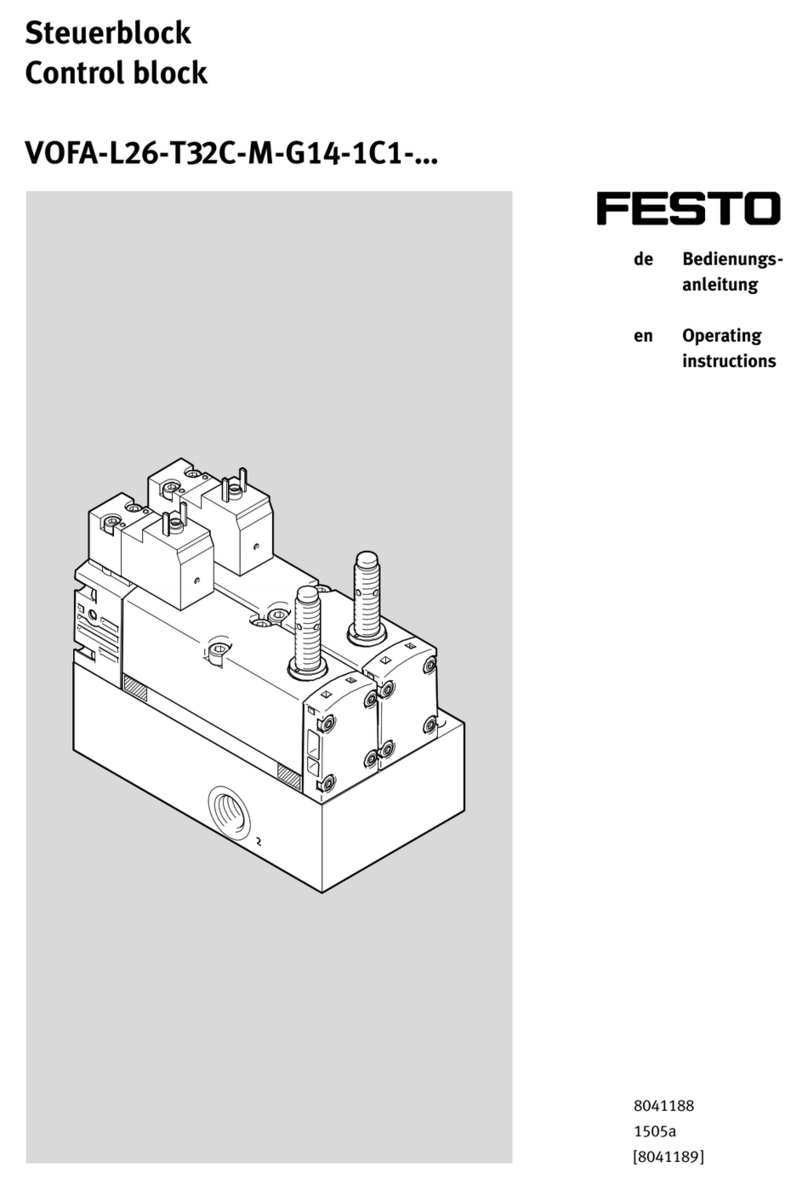

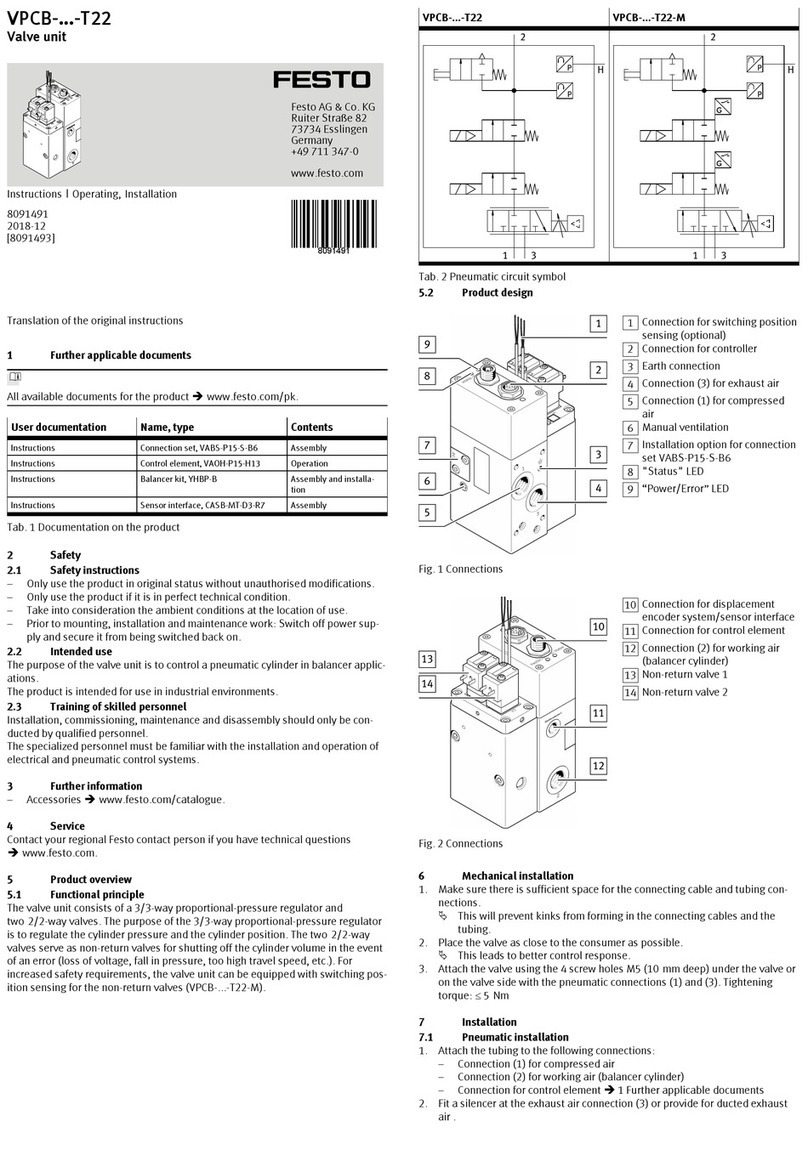

Fig. 2