5 Electrical connection

Warning

Electric voltage

Injuries caused by electric shock, damage to the machine and system.

Electrical connection may be made only by qualified personnel.

For the electrical power supply, use only PELV power circuits in accordance

with IEC60204-1/A1 (Protective Extra Low Voltage, PELV).

Take account of the general requirements of IEC60204-1 for PELV power circuits.

Use only voltage sources that ensure a reliable electric separation of operat

ing voltage in accordance with IEC60204-1.

1. Use pre-assembled cables from Festo.

2. Before establishing the electrical connection, check the connecting cable:

– Max. length of the signal lines: 30 m.

– The cables are installed free of crimping, kinking and stretching.

3. Connection of two-channel exhaust module, èOperating instructions PAHL

Note

The connection 7is used only for diagnostics. If this plug connector is used for

operation of the valve, it can result in damage to the electronic controls.

Never connect port 7to the power supply.

Always keep port 7closed with a cover cap.

4. Screw signal cable onto port 8(èFig. 1).

– Pin allocation for M12 plug:

– Tightening torque 0.5 Nm ±20 %.

Pin Cable colour1) Assignment M12 plug connector

1 – Unused 1

2

35

4

2White (WH) Analogue out+ (actual value)

3 – Unused

4Black (BK) Analogue out– (actual value)

5Grey (GY) FE

1) When using the pre-assembled Festo cables

Fig. 3

Note

With use of a screened cable:

Earth screening on the cable end away from the VPPL.

5. Screw the connecting cable to the port 9(èFig. 1).

– Pin allocation for M12 plug:

– Tightening torque 0.5 Nm ±20 %.

Pin Cable colour1) Assignment M12 plug connector

1Brown (BN) 24 V DC 1

2

35

4

2White (WH) Analogue In+ (setpoint value)

3Blue (BU) 0 V

4Black (BK) Analogue in– (setpoint value)

5Grey (GY) FE

1) When using the pre-assembled Festo cables

Fig. 4

6 Commissioning

Note

The pressure regulator PREL can only be operated together with the proportion

al-pressure regulator VPPL.

Commissioning should only be conducted by qualified personnel.

Note operating instructions of the proportional pressure regulator PREL.

With variant -40CFX2: Observe the operating instructions of the PAHL shut-off

valve.

1. Prior to commissioning, check the following requirements:

– The VPPL is flange-mounted to the PREL.

– The PREL is completely connected and ready for operation.

– The connection points are tight.

– Any necessary safety equipment is present and active.

2. Switch on the supply voltage.

3. Switch on supply pressure.

4. Switch on analogue setpoint signal (0 … 10 V/4 … 20 mA).

5. Place the VPPL and PREL into operation together (èVPPL operating instructions).

Note

The pressure regulating valve PREL has an integrated soft start function. That

means, when a setpoint value is being applied, the pressure rise at the output of

the pressure regulating valve is delayed.

7 Operation

Note

To avoid malfunctions of the setpoint value signal:

Keep sources of high frequency electromagnetic radiation (e.g. radios, mobile

phones, other interfering transmitters) away from the device.

Comply with operating conditions.

Always comply with the permissible limits.

Observe the operational status displays of the VPPL (èOperating instructions

VPPL).

Safety setting: In case of a wire break, the output pressure is lowered to

0 bar.

The VPPL interprets setpoint signals less than 1 % of full scale as 0 V.

In this case, the working pressure is set to ambient pressure.

8 Maintenance and care

Warning

Risk of injury from compressed air.

Products under pressure can cause personal injury and material damage.

Maintenance only by qualified personnel.

Before all maintenance work, depressurize the valve, service unit and piping.

Prior to all maintenance work:

1. Switch off pressure to valve and adjacent pneumatic devices.

2. Switch off analogue setpoint signal.

3. Let the device cool off.

4. Switch off supply voltage and safeguard it against being switched on again.

Cleaning:

Regularly clean the outside of the product with a soft cloth.

The permissible cleaning agent is water or soap suds (max. 50 °C).

9 Dismantling

Warning

Risk of injury from compressed air.

Products under pressure can cause personal injury and material damage.

Dismounting only by qualified personnel.

Before all disassembly work, depressurize the valve, service unit and piping.

Caution

Risk of injury from falling loads.

Take the weight of the individual device or a service unit into consideration. De

pendent on the design, an installed service unit can weigh more than 100 kg.

1. Switch off pressure to the pneumatic system.

2. Switch off analogue setpoint signal.

3. Let the device cool off.

4. Switch off supply voltage and safeguard it against being switched on again.

5. Disconnect electrical connections of the VPPL.

6. Shut down the PREL and VPPL together.

7. Remove the service unit.

– If installed before or after the service unit: Remove the compressed air line or

the connecting plate on the service unit.

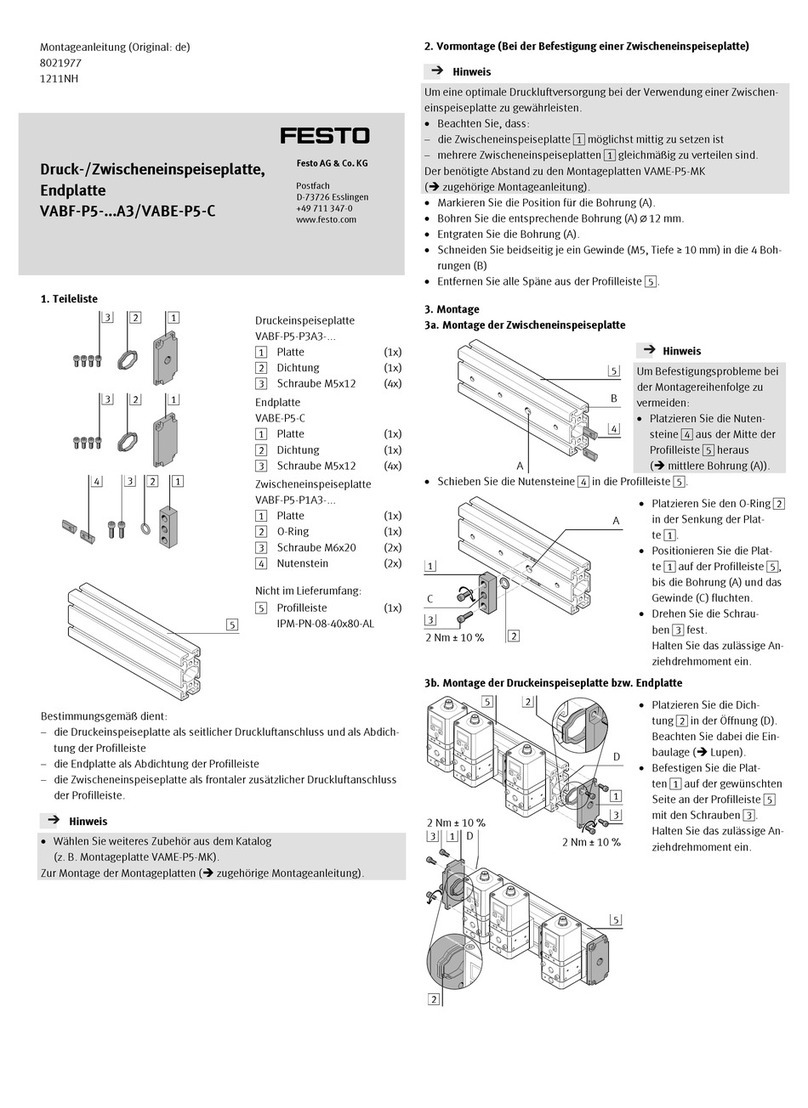

– If installed between two service units: Loosen the screws of the module con

nector.