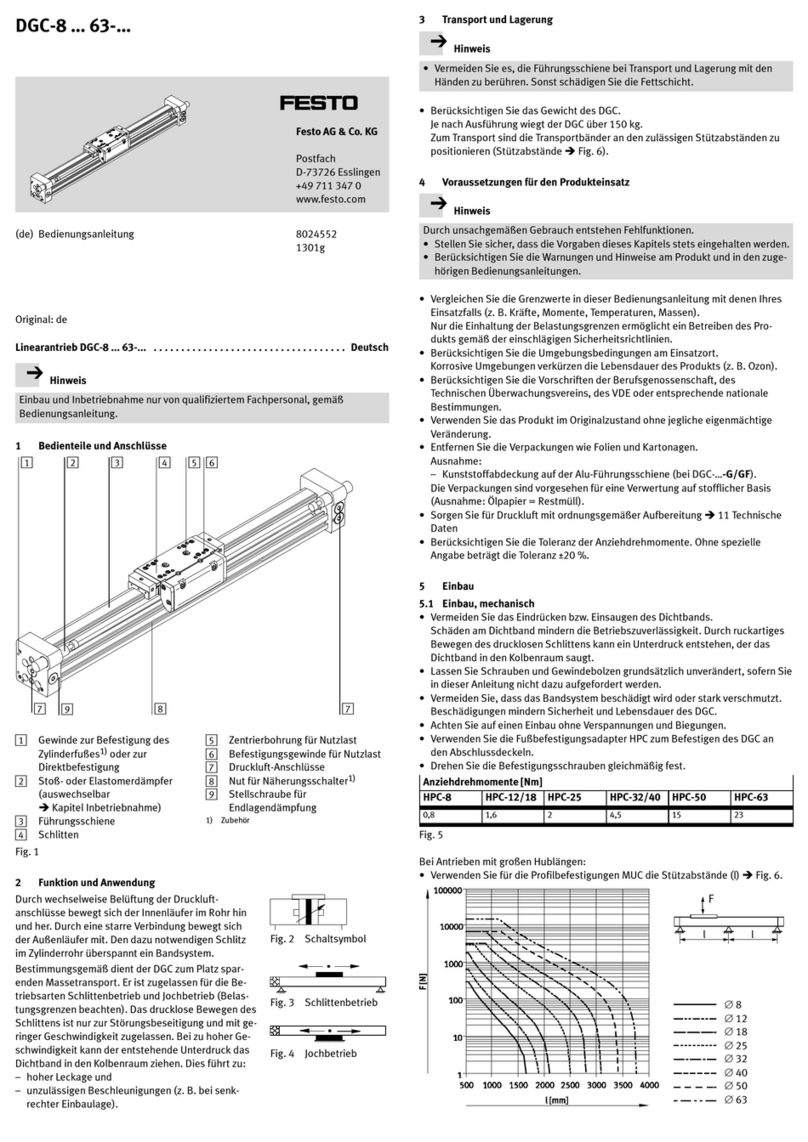

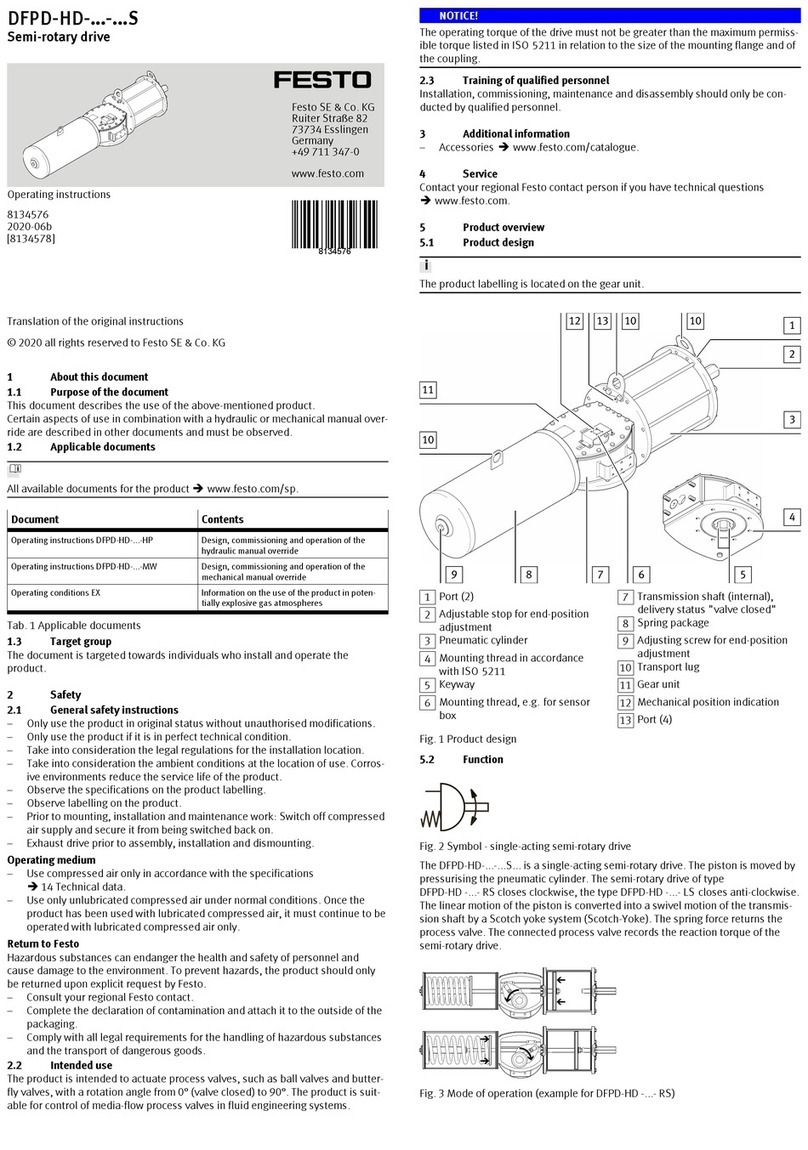

Size 32 40 50 63 80 100

Piston rod

Width across flats ß[mm] 10 13 17 17 22 22

Max. torque [Nm] 2.4 6.4 12 15 31 53

Piston rod with male thread ESBF ...

Nut, lock nut M10x1.25 M12x1.25 M16x1.5 M20x1.5

Piston rod with female thread ESBF ... F

Screw, lock nut M6 M8 M10 M10 M12 M12

Max. screwin depthtmax [mm] 12 12 16 16 20 20

Tab. 7 Information on Attachment Components

7.6 Mounting Accessories

Requirement

– No collision in the movement space of the attachment component with

mounting and sensor components.

– Protection against uncontrolled overtravel of the end positions.

– Homing to reference switch or end position.

– Query of end positions or intermediate positions.

1. Select accessories èwww.festo.com/catalogue.

2. Mount the sensor (reference or query):

– Mount the sensor rail or mounting kit (depending on the type of mount

ing).

– Align sensor and fasten it to the switching position.

Instruction manuals èwww.festo.com/sp.

Mounting kit SMB Mounting kit CRSMB Sensor rail SAMH

– Mounting on profile nose – Central mounting on the

profile

– Central mounting on the

profile

– Protect the sensor from external magnetic or ferritic influences (e.g.min. 10 mm distance to

slot nuts).

– Preferably use hardware limit switches with normally closed function (protection guaranteed

even in case of sensor failure).

Instruction manual èwww.festo.com/sp.

Tab. 8 Overview of Sensor Mountings

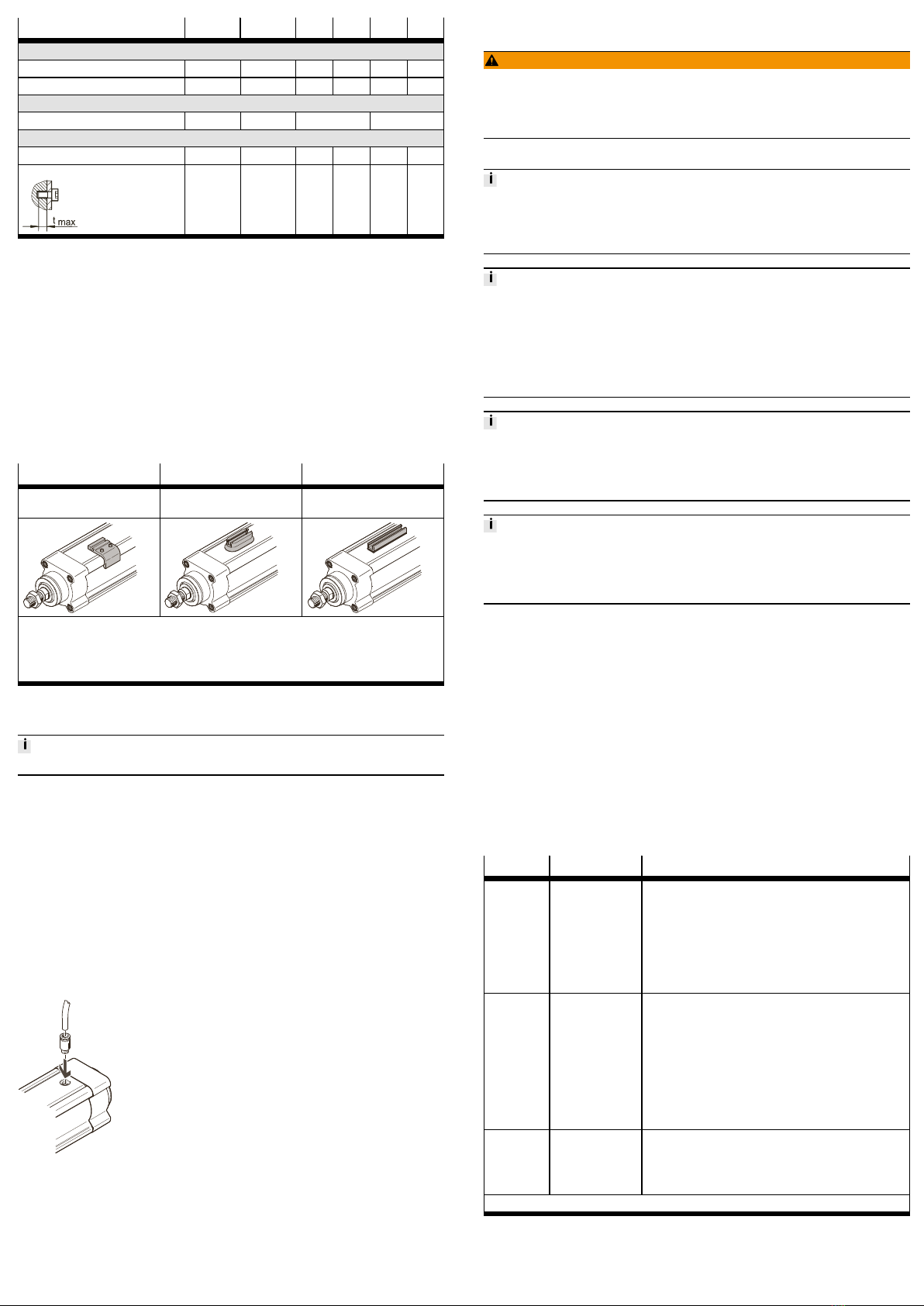

Connecting Pressure Compensation (ESBF -...- S1 only)

The standard version of the ESBF is supplied with a pressfitted sinter filter.

The pressure compensation hole permits the reduction of negative or excess pres

sure in the cylinder interior. Pressure compensation may only take place in clean

ambient air.

Alternatives to Pressure Compensation via the Environment:

– Operation in a dustfree and dry area

– Connection to a large expansion tank

– Connection of sealing air (forexample excess pressure with max. 0.2 bar).

Position of the pressure compensation port:

– ESBF32/40/50: in the drive cover

– ESBF63/80/100: in the cylinder profile

1. Remove protective cap.

2. Mount the screw fitting and connect the hose.

Fig. 4 Mount fitting (example: cylinder profile connection)

8 Commissioning

8.1 Safety

WARNING!

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

8.2 Performing Commissioning

When the motor is removed, the motor encoder loses its absolute reference to the

reference mark (e.g. by turning the motor drive shaft).

• Carry out a homing run after every motor mounting in order to establish the

absolute reference between the motor encoder and the reference mark.

Blockshaped acceleration profiles (without jerk limitation) can have the following

effects:

• High mechanical loads on the lead screw due to high force peaks.

• Overshooting effects during positioning.

• Swinging up of the entire system

Recommendation: Reduce high force peaks in the acceleration and deceleration

phases by using the jerk limitation.

Torque on the Piston Rod

During commissioning and operation, the piston rod may only be operated

without torque.

If external torques occur, an external guide must be used.

Running Noises During Operation

Identically constructed electric cylinders can generate different running noises

depending on the mode of operation, type of mounting, installation environment

and components.

Requirement

– Mounting of the drive system checked.

– Installation and wiring of the motor checked.

– No foreign objects in the movement space of the propulsion system.

– No exceeding of the max. permissible feed force and drive torque as a func

tion of acceleration, deceleration (e.g.stop function, quick stop), velocity,

moving mass and mounting position.

– No mechanical overload of the cylinder and dynamic setpoint deviation not

exceeded (e.g.overrunning the end position) due to force and torque peaks

or overshoot effects.

Limit overloads and overruns by jerk limitation, lower acceleration and decel

eration setpoints or optimised controller settings.

– Control and homing travel at reduced velocity, acceleration and deceleration

setpoints.

– No test drive to mechanical end stops.

– Software end positions ≥0.25 mm away from the mechanical stops.

Procedure Purpose Note

1. Check run Determine the dir

ection of travel of

the piston rod

– Direction of movement of piston rod (clockwise spindle):

– Retracting: Rotate cylinder drive shaft clockwise.

– Extending: Rotate cylinder drive shaft anticlock

wise.

– The direction of movement of the piston rod for positive

and negative position values depends on the mounting

position of the motor on the cylinder.

– Adapt a required reversal of direction of rotation via

parameters in the controller or controller.

2. Homing Determination of

the reference point

and adjustment of

the dimensional ref

erence system

– During the ini

tial startup

procedure

– After replace

ment of the

motor

Permissible reference points:

– Towards reference switch.

Travel at reduced velocity è 14 Technical data.

– Against the end position on the motor side.

Do not exceed maximum values

è Tab. 10 Speed and Energy in the End Positions.

Further information èInstruction manual of the drive system,

www.festo.com/sp.

3. Test run Checking the oper

ating conditions

Check application requirements:

– Piston rod travels through the complete travel cycle in

the specified time.

– The piston rod stops travel when a limit switch or soft

ware end positions are reached.

After a successful test run, the drive system is ready for operation.

Tab. 9 Commissioning Steps