Translation of the original instructions

1 About this document

1.1 Applicable documents

All available documents for the product èwww.festo.com/pk.

• Comply with the assembly instructions for the attachment elements.

1.2 Product version

This documentation describes the following product versions:

EMMB-AS-...-... Product version

K Featherkey

S Absolute encoder, single-turn

M Absolute encoder, multi-turn

B Holding brake

Tab. 1 Product version

2 Safety

2.1 Safety instructions

– Observe labelling on the product.

– Prior to assembly, installation and maintenance work: Switch off power sup-

ply, ensure that it is off and secure it against being switched back on.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– Observe tightening torques. Unless otherwise specified, the tolerance

is±20%.

2.2 Intended use

The motor is intended to be used for driving positioning systems.

2.3 Foreseeable misuse

The holding brake must not be used for braking the motor.

2.4 Area of application and approval

In combination with the UL inspection mark on the product, the information in this

section must also be observed in order to comply with the certification conditions

of Underwriters Laboratories Inc. (UL) for USA and Canada.

UL approval information

Product category PRHZ2 (USA) or PRHZ8 (Canada)

File number E342973

Standards taken into account UL 1004-1/-6, C22.2 No.100

UL inspection mark

Tab. 2 Approval information

3 Additional information

– Accessories èwww.festo.com/catalogue.

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

5 Product overview

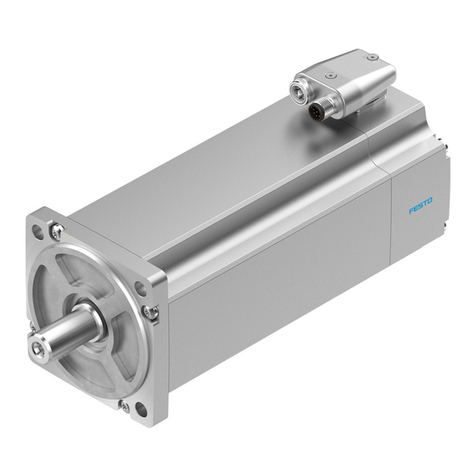

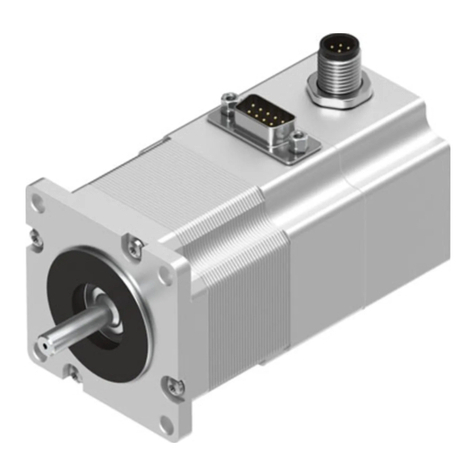

5.1 Function

The product is a permanently excited, electrodynamic, brushless servo motor. The

motor is equipped with an encoder. The encoder supplies motor data, speed and

position signals to a higher-order servo drive/motor controller in the form of digit-

al signals.

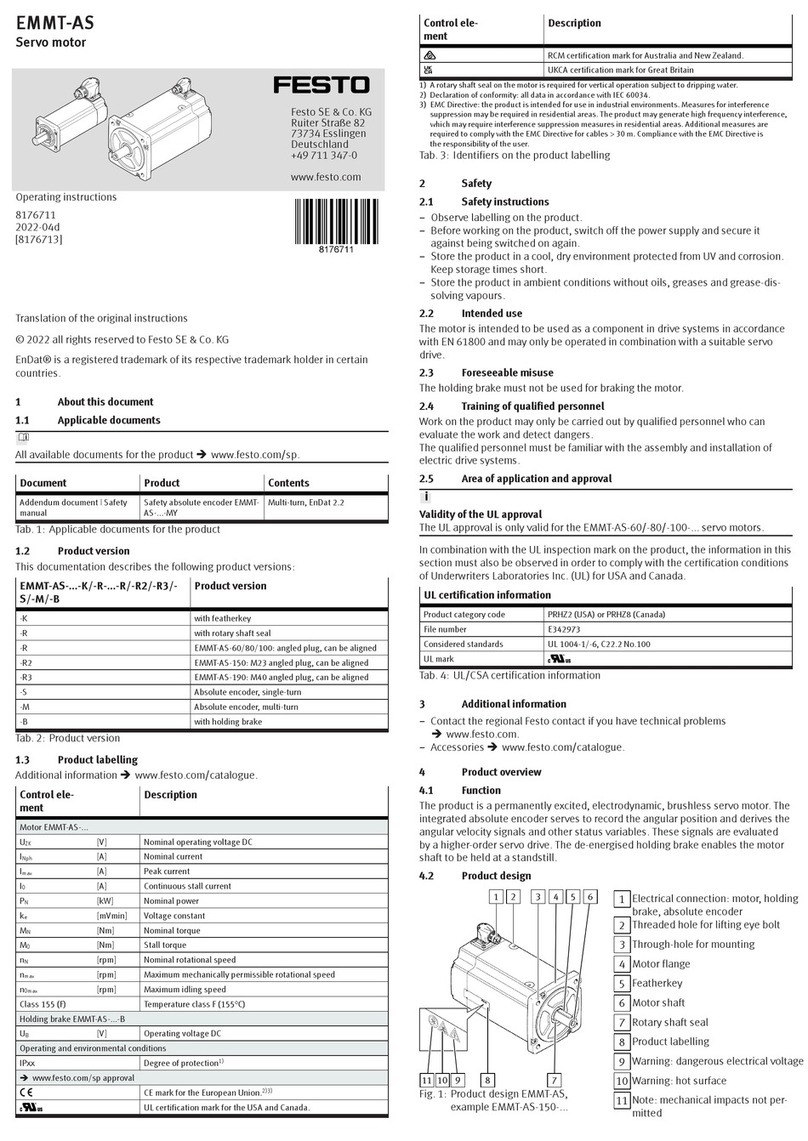

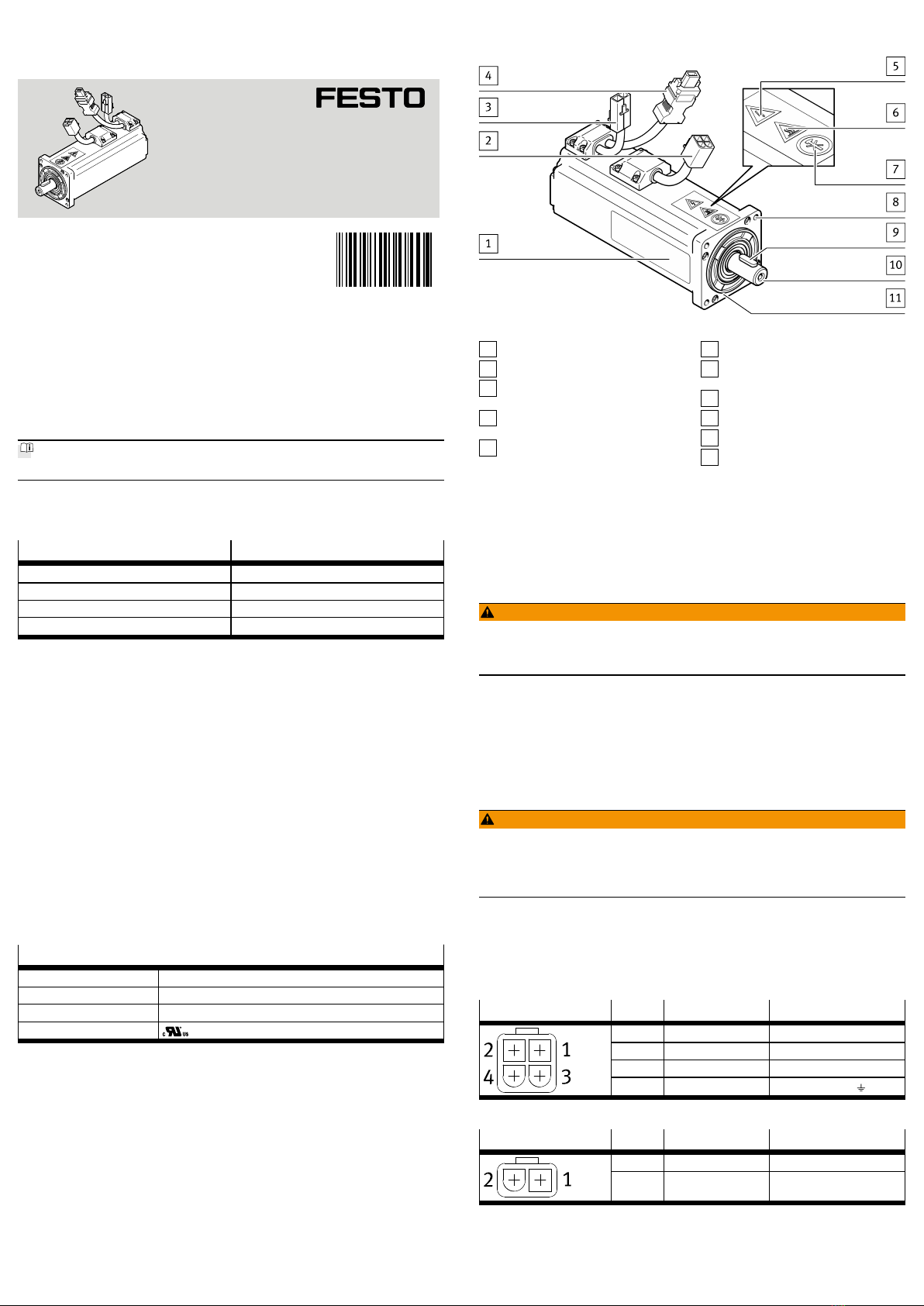

5.2 Product design

1Product labelling

2Electrical connection: motor

3Electrical connection: holding

brake (optional)

4Electrical connection: absolute

encoder

5Warning: dangerous electrical

voltage

6Warning: hot surface

7Note: no mechanical impacts per-

mitted

8Through-hole for mounting

9Featherkey (optional)

10 Motor shaft

11 Motor flange

Fig. 1 Product design EMMB-AS

6 Transport

Take product weight into account è 13 Technical data

7 Mounting

7.1 Installation

WARNING!

Risk of injury due to unexpected movement of components.

• Bring moving parts of the connected mechanical system into a secure posi-

tion (e.g.move into the lower end position).

Mount motor

1. Clean motor shaft. The motor shaft must be dry and free of grease.

2. Fasten the motor to the driven mechanical system è accompanying docu-

ments.

7.2 Mounting accessories

– Use Festo accessories èwww.festo.com/catalogue.

8 Electrical installation

WARNING!

Risk of injury due to electric shock.

• Switch off power supply prior to assembly and installation work; ensure that

it is off and secure it against being switched back on.

Cancelling the enable signal is not sufficient.

1. Connect cable to the servo drive èObserve documentation for cable and

servo drive.

2. Connect cable to the motor.

– Conductor cross-section must be adequately dimensioned.

– Use screened cables.

Motor plug, 4-pin Pin Identifier Function

1 U Motor phase U

2 V Motor phase V

3 W Motor phase W

4 PE Protective earthing

Tab. 3 Plug for motor

Connecting plug, 2-pin Pin Identifier Function

1 BR+ Holding brake, 24VDC

2 BR– Holding brake, reference

potential 0V

Tab. 4 Plug for holding brake

8101200

EMMB-AS

Servo motor

8101200

2019-04

[8101202]

Instructions| Operating

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com