CONTENTS

MAIN MACHINE COMPONENTS...............................................................................................3

CONTENTS.................................................................................................................................4

GENERAL SAFETY REGULATIONS .........................................................................................6

SYMBOLS USED IN THE MANUAL ..........................................................................................6

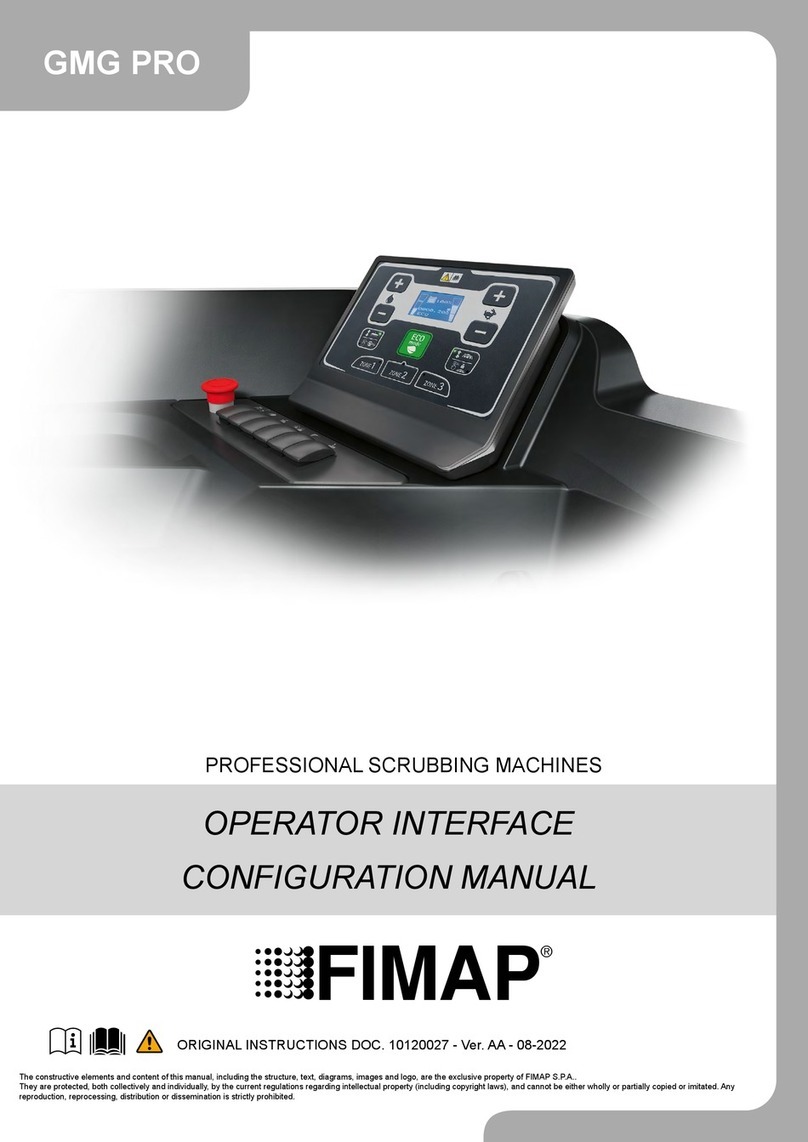

PURPOSE AND CONTENT OF THE MANUAL .........................................................................7

STORING THE USE AND MAINTENANCE MANUAL...............................................................7

ON CONSIGNMENT OF THE MACHINE ...................................................................................7

INTRODUCTORY COMMENT ....................................................................................................7

IDENTIFICATION DATA..............................................................................................................7

TECHNICAL DESCRIPTION ......................................................................................................7

INTENDED USE..........................................................................................................................7

SAFETY ......................................................................................................................................7

REGULATIONS...........................................................................................................................7

TARGET GROUP........................................................................................................................7

SERIAL NUMBER PLATE ..........................................................................................................8

TECHNICAL DATA .....................................................................................................................8

DISPOSAL ..................................................................................................................................9

SYMBOLS USED ON THE MACHINE .....................................................................................10

SYMBOLS PRESENT ON THE REGISTRATION PLATE.................................................................................... 10

SYMBOLS PRINTED ON THE MACHINE ........................................................................................................... 10

LABELS USED ON THE MACHINE..................................................................................................................... 10

SYMBOLS ON THE CONTROL PANEL................................................................................... 11

SYMBOLS ON THE CONTROL DISPLAY ............................................................................... 11

PREPARATION OF MACHINE .................................................................................................12

HANDLING THE PACKAGED MACHINE ............................................................................................................ 12

HOW TO UNPACK THE MACHINE ..................................................................................................................... 12

HOW TO MOVE THE MACHINE ......................................................................................................................... 13

MACHINE SAFETY.............................................................................................................................................. 14

TYPE OF BATTERY TO BE USED ...................................................................................................................... 14

BATTERY MAINTENANCE AND DISPOSAL....................................................................................................... 14

INSERTING THE BATTERIES IN THE MACHINE............................................................................................... 14

RECHARGING THE BATTERIES ........................................................................................................................ 14

ASSEMBLING THE BRUSH (SCRUBBING VERSION) ...................................................................................... 15

ASSEMBLING THE BRUSH (SWEEPING VERSION) ........................................................................................ 15

ASSEMBLING THE SQUEEGEE BODY.............................................................................................................. 16

INSERTING WATER SYSTEM FILTER ............................................................................................................... 16

FILLING THE SOLUTION TANK WITH WATER .................................................................................................. 16

DETERGENT SOLUTION (VERSIONS WITHOUT FSS) .................................................................................... 16

FILLING THE DETERGENT CANISTER (VERSIONS WITH FSS) ..................................................................... 17

PREPARING TO WORK ...........................................................................................................18

STARTING WORK ....................................................................................................................19

HOUR METER ..................................................................................................................................................... 20

BATTERY CHARGE LEVEL INDICATOR ............................................................................................................ 20

SCRUBBING WITH DRYING ............................................................................................................................... 20

SCRUBBING WITHOUT DRYING ....................................................................................................................... 20

DRYING................................................................................................................................................................ 21

ECO MODE.......................................................................................................................................................... 21

MANUAL MODE................................................................................................................................................... 21

PROGRAM ZONE MODE .................................................................................................................................... 21

ADJUSTMENT OF THE DETERGENT SOLUTION FLOW ................................................................................. 22

REGULATING THE FORWARD SPEED ............................................................................................................. 22

REVERSE GEAR ................................................................................................................................................. 22

4