10

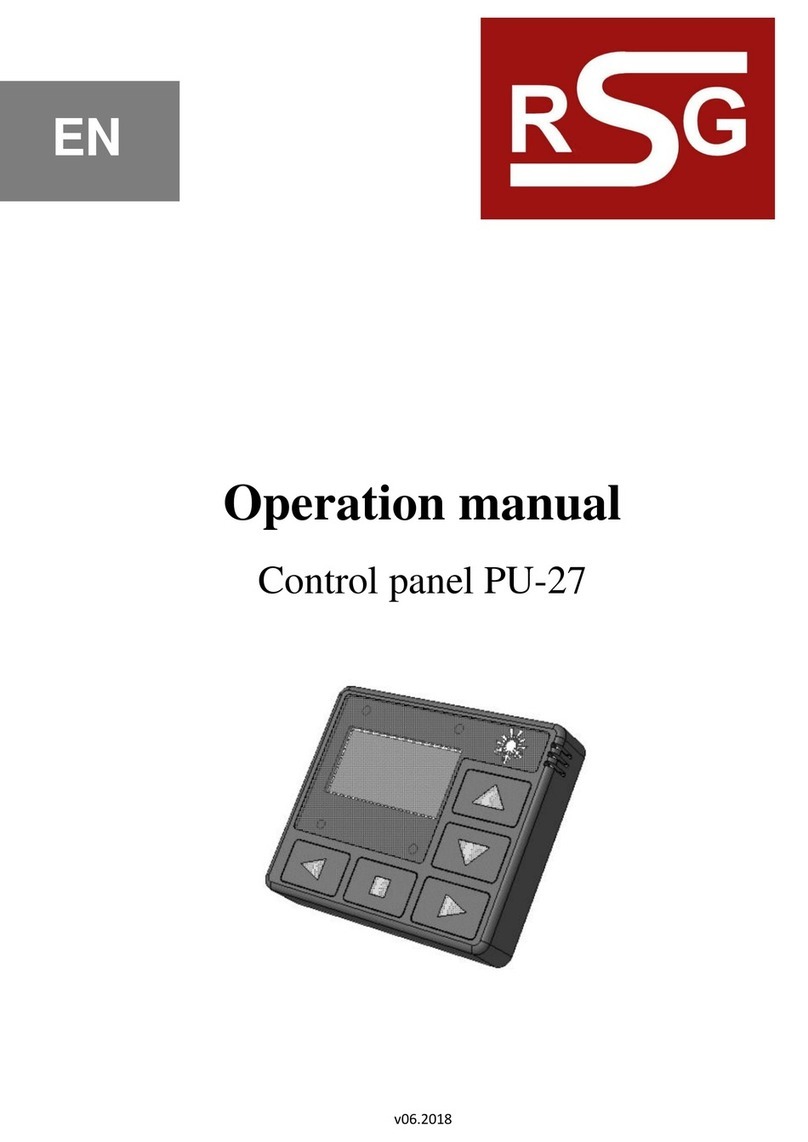

Right key: increases the contrast of the

LCD display.

Left key: decreases the contrast of the

LCD display.

4. Set the date and time on the user interface.

Ensure that the date and time are correct for

log file consistency.

To set the data and time, complete the

following steps:

a. Enter the user access password. Each digit

will be masked by an asterisk and the default

user password is 11111.

b. Press the 3key to select the Modify option on

the MAIN screen.

c. Press the 4key to select Time and Date.

d. Use the alphanumeric key to enter the Time

and Date values. The keys have the following

functions:

Right key: selects the next value to be

inserted or modified.

Left key: selects the previous value to be

inserted or modified.

ENTER key: confirms the TIME and

DATE.

ESC key: returns to the previous screen.

5. Set the system language of the user interface.

To set the system language, complete the

following steps:

a. Press the 1 key to select the Program option

on the MAIN screen.

b. Enter the installer password and press

ENTER. Each digit will be masked by an

asterisk. The default installer password is

00000.

c. Press the 8key to select System LANGUAGE.

The keys have the following functions:

Right key: selects the next language.

Left key: selects the previous language.

ENTER key: confirms the language

selection.

HELP key

An embedded help feature is available on the panel

LCD display. Press the HELP key to see the

dedicated help text for the active User Interface

screen.

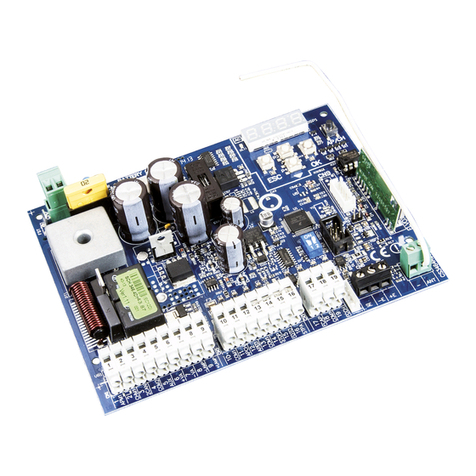

Auto-Addressing procedure

Auto-addressing allows you to make all of the devices

accessible from the panel without the need to execute

any previous configuration action on the devices,

during the installation phase or the device acquire

phase. The FC490ST is no longer required for the

manual assignment of the device addresses.

Auto-addressing allows you to know or to set the

geographical position of the devices on the site in the

device mapping phase. The auto-addressing

procedure is part of the loop devices enroll process in

the FC503 panel. Refer to the Quick Start Procedure

section in the FC503 & FC506 Addressable Fire

Control Panels Installation Manual.

To initiate the loop devices enroll process, complete

the following steps:

1. Press the 1key to select the PROGRAM

option on the MAIN screen.

2. Enter the installer password and press

ENTER. Each digit will be masked by an

asterisk. The default installer password is

00000.

3. Press the 1key to select Auto.

Note: If any loop fault such as open circuit or a

double address is detected during the enrolling

phase, the control panel display shows the

instructions to fix it. Refer to FC503 & FC506

Addressable Fire Control Panels Installation

Manual.

4. Choose the type of automatic zones

assignment. The options for automatic zones

assignment are:

1: According to the loop

2: According to the addresses of the

devices

3: Do not assign. When this choice is

made, you can reach the results phase

by:Pressing the ENTER key to activate

the AUTO- ADDRESSING phase

or

Pressing the ESC key to go to the

FAULT screen (not addressable

devices).

5. Choose the sounder trigger event. The options

for the sounder trigger event are:

1: Zone alarm

2: Panel alarm

Note: Once you select an option, the panel

executes the enrolling of already addressed

devices and enters the auto-addressing phase.

6. Press the ENTER key to activate the auto-

addressing phase or ESC key to exit.

By default, any addressable device has the address

255. The fire panel examines the serial number of

each device and assigns each an address from 1 to

250.

If the control panel finds a device with a different

address than the default, it leaves the address set at

that device.