FireClass FC500 Owner's manual

2

Table of contents

Introduction ....................................................................3

Installation......................................................................3

Select language .............................................................3

Software window appearance........................................3

Control panel connections .............................................3

Connecting the control panel locally..........................3

Connecting the control panel remotely ...................... 3

Main window ..................................................................4

File menu ...................................................................4

Tools menu ................................................................6

Help menu..................................................................7

Panel details ..................................................................7

Panel details menu ....................................................7

Communication menu................................................9

Panel language menu................................................9

Firmware update menu............................................10

Screen saver menu..................................................10

Account menu..........................................................10

Programming screens..................................................11

Loop devices programming..........................................11

Loop wiring calculation.............................................12

Detectors parameters programming........................12

Classifying detector temperature.............................14

Processing for Warning/Delay to alarm section.......14

Processing for Warning/Delay to alarm section.......16

Zones programming.....................................................18

Outputs programming..................................................20

SC1, SC2 outputs ....................................................20

General section........................................................20

General options programming .....................................21

Users........................................................................22

Communicators........................................................22

Network....................................................................23

Delays and Thresholds ............................................23

Fault delay................................................................23

Silence duration .......................................................23

Reset........................................................................24

Monostable outputs time..........................................24

Warning sound duration...........................................24

Thresholds ...............................................................24

General outputs settings ..............................................24

Pulse on....................................................................24

Detector alarm..........................................................24

Delay to alarm ..........................................................24

Warning....................................................................24

Communicators programming......................................24

PSTN interface.........................................................24

Play message after...................................................25

Periodic report..........................................................25

Address book ...........................................................25

Voice messages.......................................................25

IP Interface...............................................................25

Ethernet speed.........................................................25

Read-only options ....................................................26

General options........................................................26

Address book ...........................................................26

Advanced..................................................................26

Output polarity..........................................................26

Events.......................................................................27

Clock.............................................................................27

Log................................................................................27

Utilities..........................................................................27

Battery calculation....................................................28

User mode....................................................................29

Graphic maps...........................................................30

3

Introduction

You can program the system from the control panel (user

interface) or from a computer, using the FireClass FC500

(FC501_FC503_FC506) Console. This section describes

how to program the system from a computer. If you intend

to program the system from the control panel, refer to the

Programming from the panel chapter in the corresponding

Installation manual. To manage and program the FC501,

FC503 and FC506 control panels using a computer, you

must install the FireClass FC500 (FC501_FC503_FC506)

Console on the computer. To program the fire control

panel, use the Software FireClass FC500

(FC501_FC503_FC506) Console release 01.00.01 or

higher.

Installation

Complete the following steps to install the FireClass

FC500 (FC501_FC503_FC506) Console application:

1. Run the installer program FC500

(FC501_FC503_FC506) Console-vX.X.X.Y-

Setup.exe (vX.X.X.Y indicates the program

version).

2. Follow the required steps.

Note: Download the latest version of FireClass FC500

(FC501_FC503_FC506) Console from the FireClass

website.

Note: When the FireClass FC500 (FC501_FC503_FC506)

Console starts for the first time, it will prompt you to select

a country. To confirm, select and press the check button.

Note: To install the FireClass FC500

(FC501_FC503_FC506) Console software on the

computer, the PC configurations below are required.

Minimum required configuration:

1GHz microprocessor or better

256MB of free RAM or better

Windows XP or higher operating systems

250MB of free hard-disk space after installation

Administrator premises on the machine

Suggested configuration:

1.5GHz microprocessor or better

512MB of free RAM or better

Windows 7 or higher operating systems

250MB of free hard-disk space after installation

Administrator premises on the machine

Suggested configuration for Real-Time monitoring and

graphic maps:

2.0GHz Dual Core microprocessor or better

1GB of free RAM or better

Windows 7 or higher operating systems

2GB of free hard-disk space after installation

1280 x 1024 screen resolution or higher

Administrator premises on the machine

Select language

Select the FireClass FC500 (FC501_FC503_FC506)

Console language from the list of languages provided. To

select the application language, follow these steps:

1. Run the FireClass FC500 (FC501_FC503_FC506)

Console application.

2. Select Tools from the Main window.

3. Select Language from the drop-down menu.

4. Select a language from the Language list.

Software window appearance

To modify the appearance of the FireClass FireClass

FC500 (FC501_FC503_FC506) Console window, select

Tools from the Main window and select Skin.

Control panel connections

When using the Supervisory, Management, Downloading

and Log Management functions, you must connect the

control panel to your computer in local communication

(RS232/USB) or remote by LAN.

Connecting the control panel locally

Connect the control panel’s PCLink connector (see Figure

2, item 11, Installation manual) to one of the computer’s

serial ports using the PCLink cable (accessory item, see

Figure 1). Alternatively, use the control panel’s USB socket

(see Figure 3, item 5, Installation manual) and a USB

cable (Type A-A) or the USB cable USB5M (508.032.037)

(Length 5m).

Connecting the control panel remotely

Install the FC500IP board, as described in the paragraph

Installing the FC500IP board on page 27 of the

Installation manual.

If you do not connect the control panel to your computer,

the warning Response from Panel Timed! will display. If

the serial port for the local communication is invalid, the

warning cannot open serial port will display.

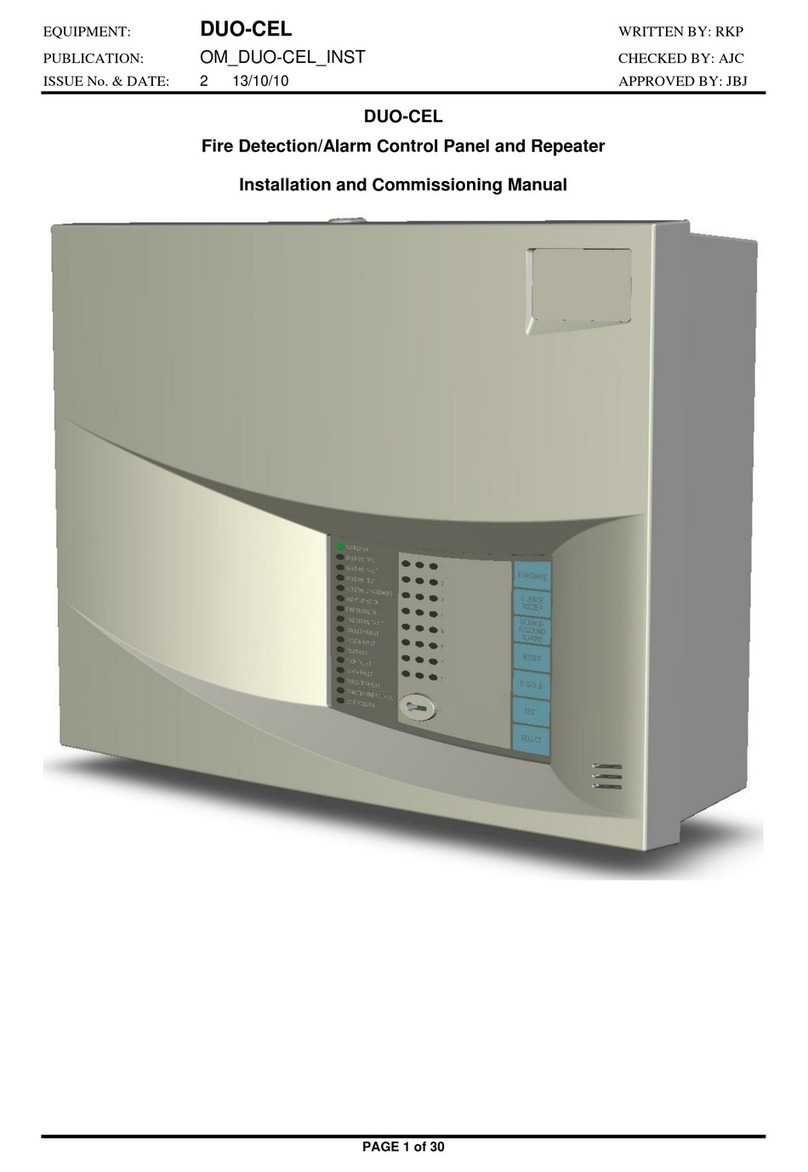

Figure 1: Schematic diagram of the PCLink cable

4

Main window

From the FireClass FC500 (FC501_FC503_FC506)

Console main screen, click File and then New, to display

the window shown in Figure 2 where you select the

firmware release of the control panel to program. Click the

green tick to accept the selection. The following selections

describe the File, Tools and Help menus.

Table 1: Icons on the Main window

Icon

Description

Click this icon, in the Master control panel, and

the window in Figure 3.2 appears. In this

window, a client panel can be inserted.

Notes:

The FC501 panel neither has any client

panel, nor can it be added as a client

panel of the FC503 or FC506 panel.

FC503 can have FC506 as a client

panel and vice versa.

Click this icon to remove the selected Client

control panel.

Opens the window Panel details where you

check or insert various programming. See Figure

5.

Checks Panel details. Enter the name and

address of the control panel or customer. See

Figure 5.

Downloads the programming via serial link or

USB or TCP/IP to the connected control panel

after entering correct installer password.

Uploads the programming of the connected

control panel after entering correct installer

password.

Selects the loop for inserting devices.

Start operations in real time. This feature allows

you to view the status of the FC501, FC503 and

FC506 control panel in real time on a computer

using the FC500IP module connected to the

network, or by using the serial port or USB port.

File menu

The File menu allows you to manage customer account

data. The following are the various selections within the

File menu.

New

Click New to create a new installation and assign the

factory default values to all programming parameters.

Open

Click Open to retrieve a previously saved customer

installation file. Locate the required installation file and

double click to open it.

Note: You can have more than one installation file open at

the same time. Pay attention to the tabs on the left side to

ensure you are editing the correct file.

Save

Click Save to save the changes in the current installation,

if you modified the installation data.

Save as

Click Save as if you created a new installation or want to

save an existing installation under a new name.

Close

Click Close to close the current installation. You will be

prompted to save any changes made.

Exit

Click Exit to close the FireClass FC500

(FC501_FC503_FC506) Console. You will be prompted to

save any changes made.

1

RS-232 Female connector, solder side

2

4 way MTA connector

3

Fire panel board

5

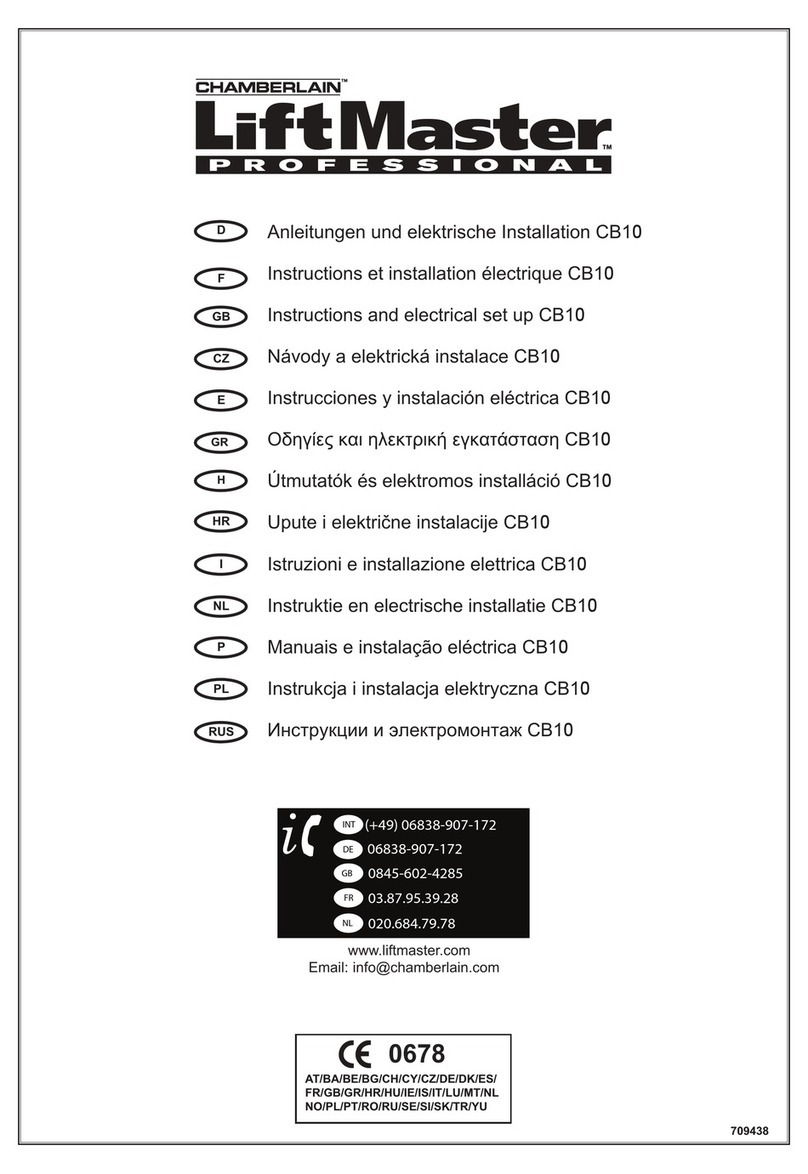

Figure 2: File menu to New display

Figure 3.1: Panel display in FC501

Note: The FC501 panel neither has any client panel, nor can it be added as a client panel of the FC503 or FC506 panel.

6

Figure 3.2: Add client panel display

Note: For the FC503 panel, you can add FC506 as a client panel and the other way around.

Tools menu

Language

See Select language paragraph.

Skin

To change the appearance of the FireClass FC500

(FC501_FC503_FC506) Console, click Tools and then

Skin to choose available appearances from a list.

Advanced

In Advanced, you can set up the Tooltips duration. Load

the driver to use the USB. You can also associate the .FCI

files generated by the programming/management of the

fire system with the FireClass FC500

(FC501_FC503_FC506) Console.

7

Figure 4: Modifying the appearance of the FireClass FC500 (FC501_FC503_FC506) Console

Help menu

Click on the Help option and a technical support file

opens. This application allows you to learn how to use the

FireClass FC500 (FC501_FC503_FC506) Console.

Panel details

Click on the Panel details icon (see Table 1) and the

following menu tabs display (see Figure 5):

Panel

Communication

Panel Language

Firmware Update

Screen Saver

Account

Panel details menu

In this window, you can enter the name of the panel and

customer.

Table 2: Icons on the Panel details menu

Icon

Description

Checks the firmware version of Main board,

Auxiliary controller, Repeater, FC500FMI

module and Plug-in board.

Restores the control panel to the factory default.

Opens the Installation manual.

Opens the define panel version window.

8

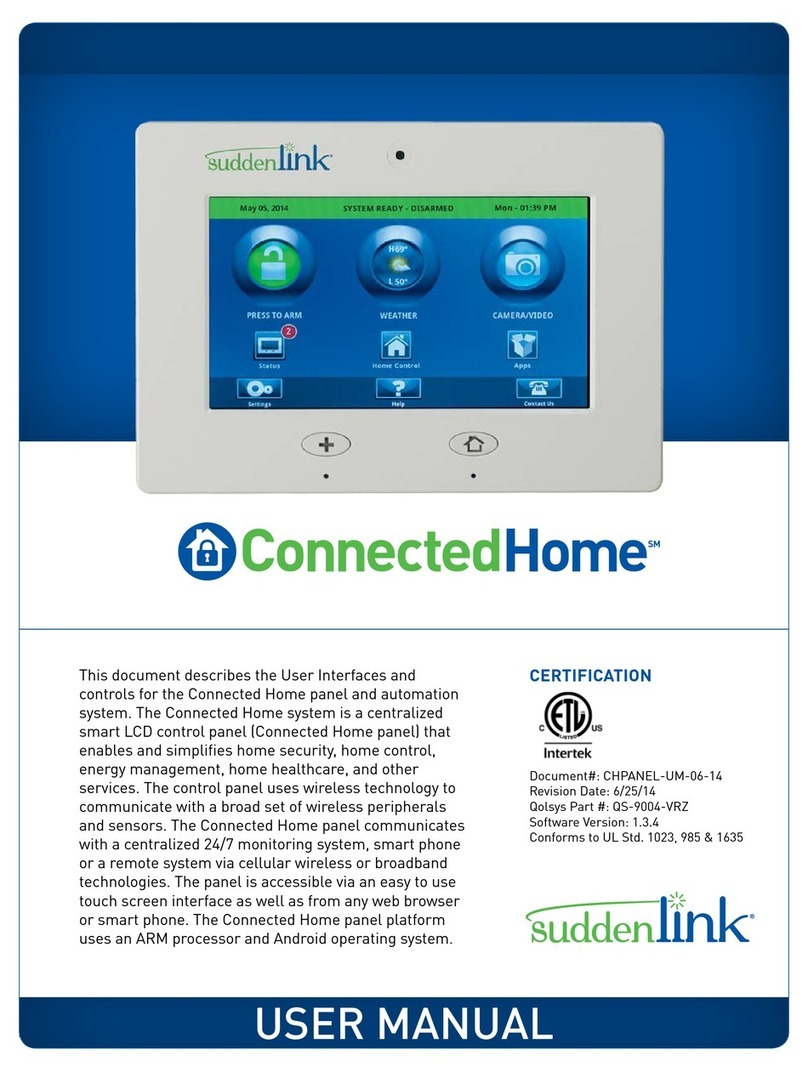

Figure 5: Panel details window

Figure 6: Communication window

9

Communication menu

In the communication menu, you can choose the

connection mode between the panel and your computer;

the options include TCP/IP, RS232 or USB.

Click on the refresh icon to update the type of connection.

Click the TEST button to verify the functionality of the

connection status. The FireClass FC500

(FC501_FC503_FC506) Console will show a pop-up that

asks you to enter an installer password every time you

want to read or write to or from the panel. The password

you enter should match with the panel installer password

for successful communication. In the TCP/IP mode, you

must enter the FC500IP parameters and Encryption key.

Use the IP module to program the parameters

corresponding to the IP module described below.

Figure 7: Entering the installer password

IP address

Enter the IP address assigned to the IP module you want

to program or, if dynamic IP address (DHCP) is selected,

contact the network administrator to request the IP

address details assigned to the IP module.

Dynamic DNS service

Control and monitor the panel remotely using ethernet, a

dynamic DNS service. You can use graphic maps without

a static IP address assigned by an internet provider to the

supervisor site. Add the necessary fields to the

configuration software in the FireClass software. This

allows you to connect to the control panel remotely using a

fixed literal domain name; for example,

mysupervisedsite.dns.org. You can avail of this site

instead of a numeric IP address. The default setting is

192.168.0.101.

IP module port

Enter the details of the port assigned to the IP module you

want to program. Contact the network administrator for

this.

IP module code

Enter the access code assigned to the IP module you wish

to program. The default setting is 5555.

Encryption key

Enter the encryption key assigned to the IP module you

want to program. The default setting is 32 zeros.

Panel language menu

The panel language menu allows you to change the

system language on the user interface or repeater to any

of the languages currently loaded. Follow the steps below:

1. In the Loaded Language section, select Change

System Language.

2. Select the language and the device, user interface

or repeater.

3. Override the language in the control panel

memory.

4. When the new language download finishes, the

panel uses the language and updates any

necessary peripherals.

10

Figure 8: Firmware update window

Firmware update menu

Click on Firmware Update; see Figure 8. From a source

file, you can carry out a firmware update of all the system

interface including the Main board, User interface, Loop

controller and Repeater.

Note: If the FC500 has a firmware version 3 or less, and

the language is Italian while English appears on the panel,

the installer must realign the language strings after the

firmware update, using the language change process; see

paragraph 8-Key System on page 47 of the Installation

manual.

Screen saver menu

In the Screen Saver menu, you can insert four lines of text,

such as installer address and telephone, which will load on

the user interface display when the panel is in standby

status. The four rows can include steady, scroll or blink.

Account menu

In the Account menu, enter the account data. For better

account identification, enter the address, click on the

address field and the software attempts to find the address

on Google maps if you have an internet connection.

11

Figure 9: Account window

Notes:

It is not mandatory to fill out the Notes field.

Do not add any personal data to the Notes field.

Programming screens

The programming screens of the system are the following:

Loop devices

Zones

Panel outputs

General options

Communicators

Clock

Log

Utilities

User mode

See more information on these screens in the following

sections.

Loop devices programming

On the left side of the window, click the panel name to

expand the tree view. Then click on the required loop, 1,

2 or 3. The devices programming window will display. See

Figure 10.

Note: On the right of Loop 1, Loop 2 or Loop 3, the

current number of devices is shown in brackets.

Table 3: Icons in the tool bar

Icon

Description

Add device: Select new devices.

Removes device: Remove the install devices.

Copies device on the clipboard: This allows you

to copy device data to the clipboard for use in

another account.

Pastes clipboard content: This allows you to add

device data previously copied to the clipboard.

Read loop: This allows you to upload the current

loop data from the panel.

Send elements: This allows you to download the

current loop data to the panel.

Device’s details: This opens a new window

where you can see the device status.

Selection: This allows you to select all devices

or invert the current selection.

12

Print to file: This allows you to print the list of

devices of the selected loop to a .csv file. You

can edit the .csv file using Microsoft Excel.

Note: If different devices have common programming

parameters, you can use the multiple selection of the

devices and assign the same parameters.

Select devices

1. Click on Panel 1.

2. Select Loop 1, Loop 2, Loop 3, Loop 4, Loop 5 or

Loop 6.

3. Click on new device. The window in Figure 10 will

display.

4. Select the programming device, check the address

(auto addressing) and click on the link.

5. Click Enable to add the device to the loop. For

other devices, repeat the same procedure. The

icon in the Features field represents the detector

type.

Remove devices

1. Select the device in the list.

2. Click the Remove device icon.

3. Click YES to remove or NO to cancel. See Figure

10.

Loop loading

Find the Loop load section at the bottom of the

programmed devices list. See Figure 11. This section

displays the number of Activation points on the loop, the

Drain in standby, the Drain in alarm and the Signal drain.

You can also adjust the Alarm percentage.

Note: You may enter remote LEDs in the calculation.

The percentage shown in the Loop drain in alarm (100%)

is the programmed value in Battery calculation; an option

of the Utilities screen for the battery calculation after you

enter the cable length. You can choose the type of cable if

you have a database.

Figure 10: Loop devices programming window

Loop wiring calculation

The loop wiring is located beside the Loop load tab. This

gives you the maximum permitted resistance of the loop

based on the cable length and the Alarm percentage. If

cable data is available from the Utilities section, then a

suitable cable may also appear.

Detectors parameters programming

Click on a device in the Device list. The relevant device

programming window appears on the right; every device

13

has the dedicated programming window. To view the

detectors, see Figure 10.

First section (General)

Enabled: A tick indicates that the detector is

enabled.

Label: This indicates the editable device-label.

The system uses the label as the device identifier.

Address: In this field, you can modify the detector

address.

Options

LED blinking: A tick indicates that the LED detectors will

flash.

Assigned zones: Each Fire detector, Input

module and Manual callpoint can be associated

with one of the available software zones; 32 for

the FC501, 128 for FC503 and 256 for the FC506

control panel. If a device goes into Alarm status,

the zones assigned to it will also go into Alarm

status.

Base

In this section, it is possible to select the detector base by

clicking on the available bases. When you select the

sounder base type, a new programming tab Base is

available, which opens the sounder base programming

screen. On this screen, you can select the trigger zones,

the trigger points and the trigger events conditions and you

can configure the following parameters.

Table 4: Base parameters for detectors

Parameter

Result

Enabled

When selected, the base is enabled.

Otherwise, the base is disabled.

Label

20 characters base label

Silenceable

Rings until you select the

Silence/Resound sounders button.

Otherwise, ringing continues until you

select the Reset button.

Set as SC1

When selected, the base behaves as

the sounder circuit 1 (SC1).

Monostable

When selected, the base rings until the

Monostable outputs time elapses.

Remote LED

In this section, you can activate the programmable Remote

LED of the detectors. The detectors have an output used

to drive the remote LED. This output is only activated for

the detector alarm to which it belongs. Now, you can

program the output to activate for other events, exactly as

activation occurs for other panel outputs, as well as for the

detector alarm to which it belongs.

Note: You can program the Remote LED on the control

panel user interface, in the detectors programming page.

14

Figure 11: Detectors parameters programming window

Table 5: Detector classification temperature

Detector

Class

Typical

application

Temperature °C

Max.

Application

Temperature

°C

Min.Static

Response

Temperature

°C

Max.Static

Response

Temperature

°C

A1

25

50

54

65

A2

25

50

54

70

B

40

65

69

85

C

55

80

84

100

D

70

95

99

115

E

85

110

114

130

F

100

125

129

145

G

115

140

144

160

Classifying detector temperature

Detectors will conform to one or more of the following

classes: A1, A2, B, C, D, E, F or G. Optionally,

manufacturers may give additional information concerning

the response type exhibited by the detector, by adding the

suffix S or R to the above classes. Detectors, with a suffix

S to their class, do not respond below the minimum static

response temperature, even at high rates of rise of air

temperature. Detectors, with a suffix R to their class,

incorporate a rate of rise characteristic, which meets the

response time requirements for high rates of rise of air

temperature, even when the air temperature starts

substantially below the typical application temperature

(EN54-5:2000).

Processing for Warning/Delay to alarm section

This section determines the actions the control panel

performs when the device threshold exceeds.

Use zone settings: The detector uses the

parameters of the assigned zone; if this option is

disabled, you can manually select the Warning or

Delay to alarm time.

Delay to alarm: The control panel will activate the

Alarm delay.

Warning: The control panel will activate a

Warning signal.

Depending on the detector in question, smoke, heat,

smoke and heat, heat and carbon monoxide (CO), smoke

15

heat or carbon monoxide, it will have three sections

outlined in Table 7.

Table 6: Icons for modes

Icon

Description

Day mode

Night mode

Table 7: Detector sections

Section

Description

Operating mode heat detector section

Use Day mode. Night mode is for temperature

detector, see Table 5. Choose the class of the selected

detector.

Operating mode smoke detector section

Use Day mode. Night mode is for smoke and heat

detectors:

Drift compensation: Drift compensation

affects optical smoke sensors only. It will

supply a precise analysis about dust

accumulation, and therefore, the alarm

threshold will modify accordingly (false

alarms).

Default: For smoke detectors and smoke and

heat detectors only.

Enhanced: For smoke and heat detectors

only.

Sensitivity: You can set sensitivity at Low,

Medium and High.

Operating mode carbon monoxide section

Use Day mode. Night mode is for carbon monoxide

and heat detectors:

Default

Enhanced

Disabled

Sensitivity: You can set this to Low, Normal

or High. You can set the FC460PC detector,

(smoke, heat and carbon monoxide) to High

Immunity or Universal in the triple technology

detection.

Note: Click to open or close the relevant section of

parameters programming.

Note: If a detector linked to an output or an input-output

module is disabled (remove a tick in the proper section) a

window will ask for confirmation. Click on Detail to see

further data.

Note: For FC410LPA/S series sirens and FC430LPA/S

base, in the Sounder options section, you can set the tone,

volume and frequency of the beacon flash.

Note: For the FC410LPSY/AV series sirens, you must also

choose the subtype.

Input module parameters programming

Click on an input module entered, and the relevant

programming window appears as per the following

description.

First section

See the Detectors section.

Assigned zone

See the Detectors section

Second section

Select the operating mode style B or C. There are two

operating mode styles, B and C.

B style: A two wire connection mode: the short-

circuit condition as an Alarm condition.

C style: A two wire connection mode: the short-

circuit condition as a Fault condition.

Note: As you select different styles, the electrical

operating diagram changes.

16

Processing for Warning/Delay to alarm section

See the same section in the Detectors parameters

programming.

Note: For every digital input of loop devices, the

Restorable warning parameter (when you select the

Warning option for the input) can be programmed. This

can also apply to the Multiple Input-Output modules, but

not for the detectors. When this option is programmed for

a certain input, the control panel will enter the Warning

status when the appropriate conditions are detected by the

input; the control panel exits this status when the loop

device returns to standby status.

Note: When the loop device is activated and the Warning

event is generated, the device LED will switch ON. When

the event is restored, the LED will switch OFF.

For the FFC410DDM module only, you can set the gas

detection thresholds by selecting Conventional for

conventional detectors and Gas source or Gas sink for

signalling detectors. In addition:

LED blinking: Click on this to enable or disable

the signalling LED module.

External power: Click on this to enable or disable

an external 24Vdc PSU.

For the MIM module, you can enable Fast mode in style B

or Style C/NO connection. When you enable Fast mode,

the control panel will detect the module activation in 2

seconds.

Note: A short circuit fault will be detected quickly while its

restoration will be slow, as with other faults. The default

status is disabled.

Output module parameters programming

Click on an Output module entered and the relevant

programming window appears as per the following

description.

First section

See the Detectors section

Second section

For trigger zones, each Output module can be triggered by

up to 4 of the available software zones of the FC501,

FC503 and FC506 panels. The available zones are: 32 for

FC501, 128 for FC503 and 256 for FC506. An Output

module will be activated when any of the selected zones

are triggered, reaching the status condition configured in

the fourth section (zone row).

Base

In this section, you can select the base for the Output

module. Click on available bases for FC430SAM and

FC430SAB only. Once you select the sounder base, you

can choose a new programming tab labelled base that

allows access to the sounder base programming page;

here, you can select the trigger zones, the trigger points,

the trigger conditions, and you can configure the following

parameters.

Table 8: Base parameters in output module

Parameter

Result

Enabled

When selected, the base is enabled.

Otherwise, the base is disabled.

Label

20 characters base label

Silenceable

Rings until you select the

Silence/Resound sounders button.

Otherwise, ringing continues until you

select the Reset button.

Set as SC1

When selected, the base behaves as

the SC1.

Monostable

When selected, the base rings until the

Monostable outputs time elapses.

Beacon

This activates the blinking or ON status

Third section

For trigger points, each output module can be assigned

three activation points; in this case, the Output module

activates when at least one of the input points to which it

belongs is in an Alarm status. You must indicate:

The loop which the device connects to

The device address

Fourth section

For Options, you can select the conditions that will activate

the output module. Options include:

Zone warning, Zone fault, Zone delay to alarm,

Zone alarm, Zone double knock, Zone test.

Point warning, Point fault, Point delay to alarm,

Point alarm.

Panel warning, Panel fault, Panel delay to alarm,

panel alarm

Network warning, Network fault, Network delay to

alarm, Network alarm

You can also program the output module as Silenceable,

Set as SC1, Active on disablement, Monostable, Timed

warning. See Outputs programming.

17

Linked delay: See the same option in the section

Outputs programming.

For the following types of devices, FC410LPAV (all

versions), FC430LPASB, FC430SAB (with FC430SB), in

addition those devices certified to EN54-23, FC410LPS-

R/W, FC410LPBS, FC430LPBSB, you can separate the

sounder and beacon programming into two different

programming tabs. These programming tabs have the

same programming options, except for Set as SC1 that will

only be present for the sounder output.

Note: It is not possible to separately enable or disable the

two output channels.

Note: The separate sounder and beacon programming of

the devices above is also possible using the Control panel

user interface in the Devices programming pages.

Pulse on

If the Pulse on option is disabled, the sounder rings

steadily. If not, the sounds rings 2 seconds on, 2 seconds

off, as indicated by the options below. In all cases, the

sounder tone is based on the selection in the Options

page.

Note: The sounder rings continuously for the Fault, Double

Knock and Test events.

Note: Disable As general options to make the Pulse on

options of the selected sounder different to the settings in

the General outputs settings screen.

Detector alarm

If enabled, the sounder will ring when the programmed

Alarm event is triggered by a detector. The default status

is disabled.

Note: The sounder will ring continuously when the

programmed Alarm event is triggered by a callpoint or

Evac button, independently by the Detector alarm option

set.

Delay to alarm

If enabled, the sounder rings when the programmed Delay

to alarm event occurs. The default status is disabled.

Warning

If enabled, the sounder rings when the programmed

Warning event occurs. The default status is enabled.

Sounder options

In the loop sounders programming page, there are three

controls to set the Tone, Volume and the Beacon

frequency for Alarm, Delay to alarm and Warning event

types so that each event type causes a different sound or

LED blinking. If different types of trigger events are active

at the same time for a sounder, this rings with the highest

priority tone.

Note: Disable As general options to make the Sounder

options of the selected sounder different to the settings in

the General outputs settings screen.

Default volumes

Maximum for Alarm and Delay to alarm, minimum for

Warning.

Default beacon frequencies

0.5Hz.

Multiple input-output module-parameters programming

(FC410MIO/FC410QIO)

Click on the Multiple input/output module entered,

FC410MIO, three inputs and four outputs module, or

FC41OQIO, four inputs and four outputs module, see the

customised manuals, and the relevant programming

window will appear.

The options descriptions are the same as the Input and

Output modules paragraphs. In the field Label, a

description of Input/Output module will be inserted. For

trigger points, see the same section in Output module

parameters programming.

Options section

Opps interface: ActUnit/KeySafe allows you to

manage the procedure for the automatic opening

of the factory, office, shop, warehouse doors in

case of fire. This avoids the breakage of these

structures. The module outputs can control these

actions.

LED blinking: Click on this to enable or disable

signalling LED. The FC410TSM door control

module, one input or one output, closes a fire door

in the case of an alarm or a fault. The FC410TSM

monitors the external power supply and loop

voltage test, if the relevant option is enabled.

Note: In an eventual connection on the right side, a two

wires connection, the module enables the yellow isolator

LED blinking. This signals an incorrect installation.

Manual callpoint parameters programming

Click on the Manual callpoint, FC420CP and FC421CP,

the relevant programming will appear as per the following

description. The General section is the same as the

Detectors section.

18

Options section

Assigned zones: Each manual callpoint can be

associated with one of the available software

zones (32 for FC501, 128 for FC503 and 256 for

FC506).

LED blinking: If you enable this option, the

manual callpoint LED blinks on every loop

scanning.

Zones programming

The Zones option from the panel tree menu allows you to

access the software zone parameters; see Figures 12.1,

12.2 and 12.3. The software zones parameters are applied

automatically to all devices associated with the zone

concerned.

First section (General)

Enabled: A tick indicates that the detector is

enabled.

Label: This indicates the editable device-label (up

to 20 characters). The system uses the label as

the zone identifier.

Options section

You can program a number of parameters in this section.

Walk test

Active: If enabled, the zones in Alarm status

activate the programmed outputs with Walk test

event, while the control panel does not generate

an alarm. Select this option if the event is

generated by any device (modules, callpoints, and

detectors), callpoints (callpoints only) and

detectors (modules and detectors, but no

callpoints).

Delay to alarm

Delay to alarm: If you enable this option, the

control panel activates the Alarm delay.

Double knock: If you enable this option and the

zone is in Delay to alarm status; when you activate

any other devices or other addresses associated

to this zone, the zone will generate an Alarm

status immediately.

Note: If the Use zone settings option is unchecked for a

device, you can decide for that device if it must process

Warning and Delay to alarm statuses. Once you decide

that the device processes the Delay to alarm status, the

activation causes the Delay to alarm of the panel (with

panel Delay to alarm time); as the device belongs to a

zone, that zone will also go into Delay to alarm status. If

another point belonging to the zones goes into Delay to

alarm status, the Double knock option becomes active if

enabled in the Zone programming page.

Delay to alarm duration: An input device

programmed with Delay to alarm time will

generate an Alarm status when the Delay to alarm

time elapses. See Detectors parameters

programming. To change the Delay to alarm time,

select Delay to alarm and you can set the time

from 0 seconds to 300 seconds in 1 second steps.

Drift compensation: See the same option in

Table 7.

Detector warning: If you enable this option, the

control panel activates a Warning signal. To

activate the Warning option for a module, tick the

corresponding box on the module programming

screen.

Smoke delay: For each zone, you can program

the delayed activation of the smoke detectors. The

Smoke delay (60 seconds or 30 minutes)

parameter, when set, applies to all smoke

detectors assigned to the selected zone, the alarm

verification algorithm as described in EN54-2.

Note: Under the list of Zones (Zone programming page,

see Figures 12.1, 12.2 and 12.3 ) two windows display

which devices and what outputs are enabled. If you click

the right mouse button on a device in the list, a new menu

displays. Selecting device details opens a new window,

where it is possible to see what points and output is

assigned to the device.

Communicators section

PSTN

You can associate each zone with one or more voice

messages linked to an Alarm, Delay to alarm, Start-up,

Breakdown or Walk test event. You can send these voice

messages to a maximum of 32 telephone numbers.

IP

See PSTN above.

Note: The communicators section activates after the

PSTN and IP communicator are enabled (double click for

this) in the General options page.

19

Figure 12.1: Zones programming window for the FC501 panel

Figure 12.2: Zones programming window for the FC503 panel

20

Figure 12.3: Zones programming window for the FC506 panel

Outputs programming

The Panel outputs option allows you to access the output

parameters. The relevant programming appears as per the

description in Figure 13.

SC1, SC2 outputs

These are supervised, silenceable, bypassable (disabled)

Alarm outputs. For an Active output, pull up to 27.6V on

the positive terminal; pull down to 0V on the negative

terminal. When you click on an output, the relevant

programming window appears.

General section

Enabled: A tick indicates an enabled output.

Label: This is for the editable Output-label. The

system uses the label as the Output identifier.

Zones

In the Zones section, it is possible to trigger each output by

up to four of the available software zones (32 for the

FC501, 128 for FC503 and 256 for the FC506 fire panel).

Trigger points

In the Trigger points section, it is possible to trigger each

output by three input points. For each point, you need to

indicate the device address; in the case of FC506, you

need to indicate both the loop number and device address.

Options

In the Options section, you can select the conditions that

will activate the outputs. For example, if the Zone warning

option is enabled, the control panel activates the output

when one of its associated points goes into Warning

status.

Warning zone, Fault zone, Delay to alarm zone,

Alarm zone, Double knock (see Zones

programming), Walk test zone

Point warning, Point fault, Point delay to alarm,

Point alarm

Panel warning, Panel fault, Panel Delay to Alarm,

Panel alarm, Network RS485 fault

Set as SC1. If this option is enabled, the output

behaves as SC1.

This manual suits for next models

3

Table of contents

Other FireClass Control Panel manuals

FireClass

FireClass FC501-L Technical manual

FireClass

FireClass Precept EN Panel User guide

FireClass

FireClass FC501-HK User manual

FireClass

FireClass FC503 User manual

FireClass

FireClass 500 User guide

FireClass

FireClass FC503 Technical manual

FireClass

FireClass FC501 Series User manual

FireClass

FireClass FC600 User manual

FireClass

FireClass FC-P-S Installation and user guide

FireClass

FireClass FC503 User manual