FLIR A400 Series User manual

Other FLIR Digital Camera manuals

FLIR

FLIR Exx series User manual

FLIR

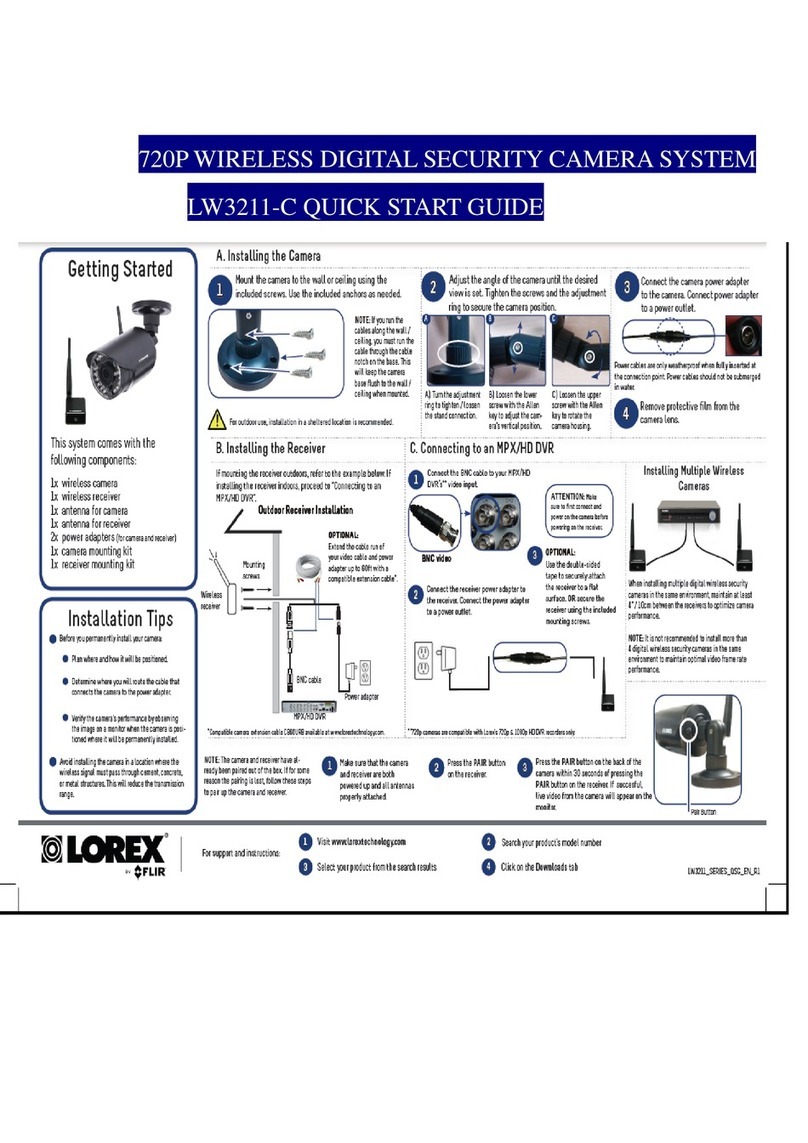

FLIR Lorex LW3211-C User manual

FLIR

FLIR BLACKFLY USB3 Vision User manual

FLIR

FLIR Ariel CM-3202-11-I User manual

FLIR

FLIR Exx series User manual

FLIR

FLIR M-Series User manual

FLIR

FLIR Quasar Gen III CP-6302 Series User manual

FLIR

FLIR FIREFLY User manual

FLIR

FLIR Tau User manual

FLIR

FLIR Tau User manual

FLIR

FLIR Scout Bi-Ocular User manual

FLIR

FLIR ZENMUSE XT2 User manual

FLIR

FLIR BLACKFLY S GIGE User manual

FLIR

FLIR AX Series User manual

FLIR

FLIR CP-4221-300 User manual

FLIR

FLIR Flir MPX User manual

FLIR

FLIR USB3 Vision GRASSHOPPER 3 User manual

FLIR

FLIR GRASSHOPPER 3 Series Use and care manual

FLIR

FLIR A310 ex Series User manual

FLIR

FLIR Ariel CM-3102 Manual