8 GB/IE

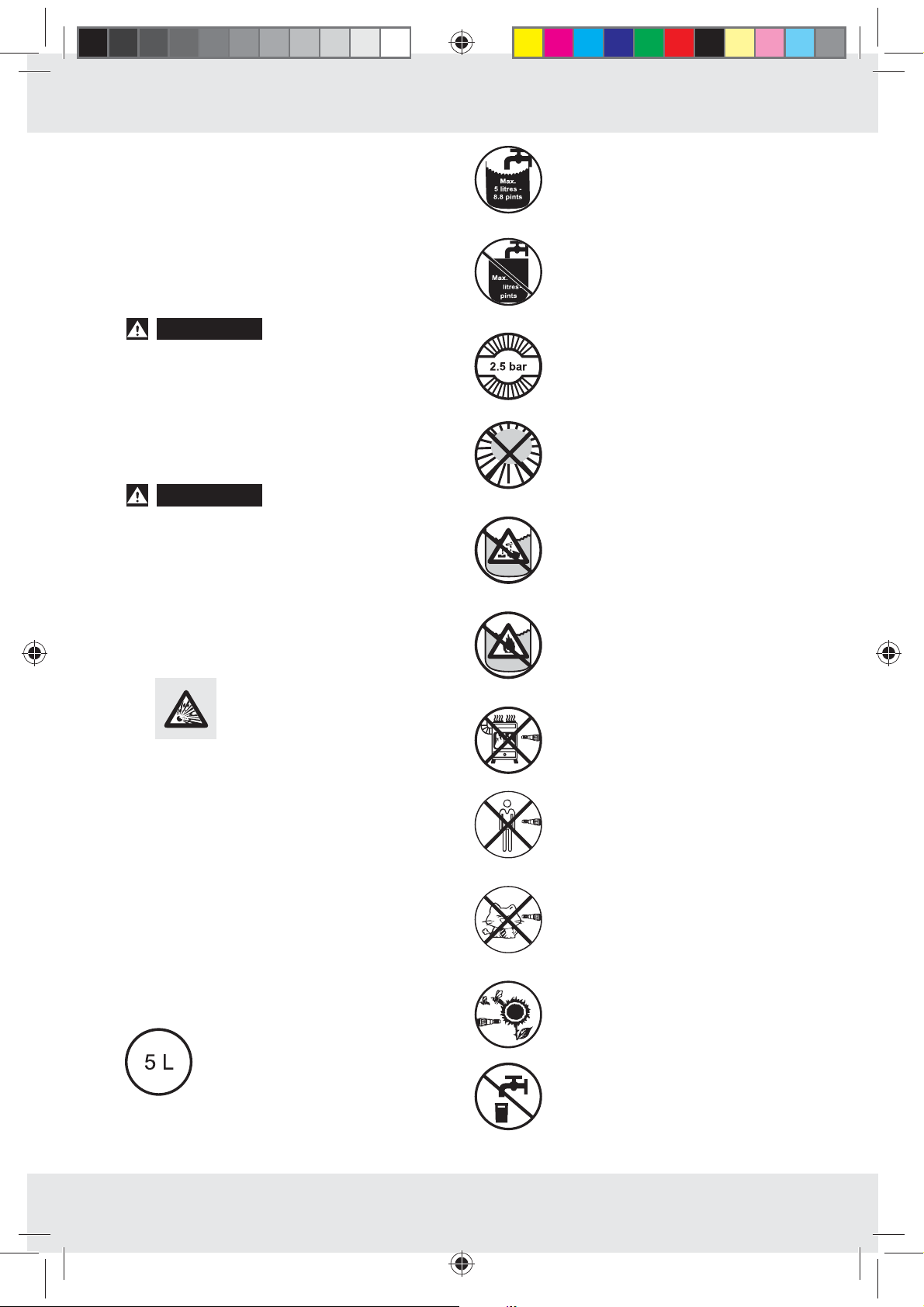

Fill the device only with liquids at

temperatures of 0 - 40 °C.

Before use

CAUTION! Check that the device is

functioning properly! Check the pressure

sprayer before each use to ensure that it

is free of visible damage and is func-

tioning safely. To do this, carry out the

following tests and inspections:

Check the tank 5, the suction hose 12

and the carry strap

6

for visible damage.

Check that the hose connections are fitted

tightly.

Check that the pipe connections are fitted

tightly.

Pump the empty pressure sprayer to

approx. 2bar.

The pressure must not fall more than ap-

prox. 0.5bar in a space of 30 minutes.

Pump the pressure sprayer to approx.

2bar.

Pull the safety valve 3up to the stop.

You must be able to hear the pressure

escaping.

Bringing into use

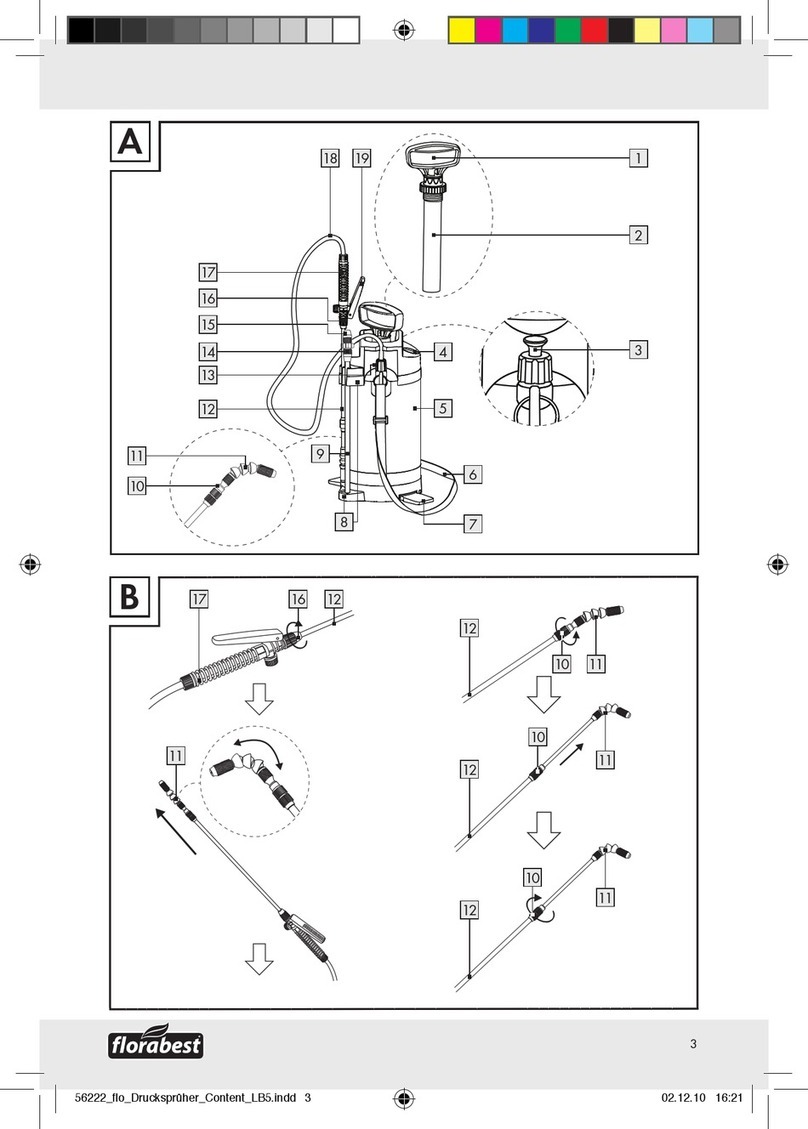

Attaching the spray tube

(Fig. B)

Turn the union nut 10 anticlockwise to

release it from the handle 11. Push the

spray tube 8into the handle 11 as

far as it will go.

Tighten the union nut 10 by turning it

clockwise.

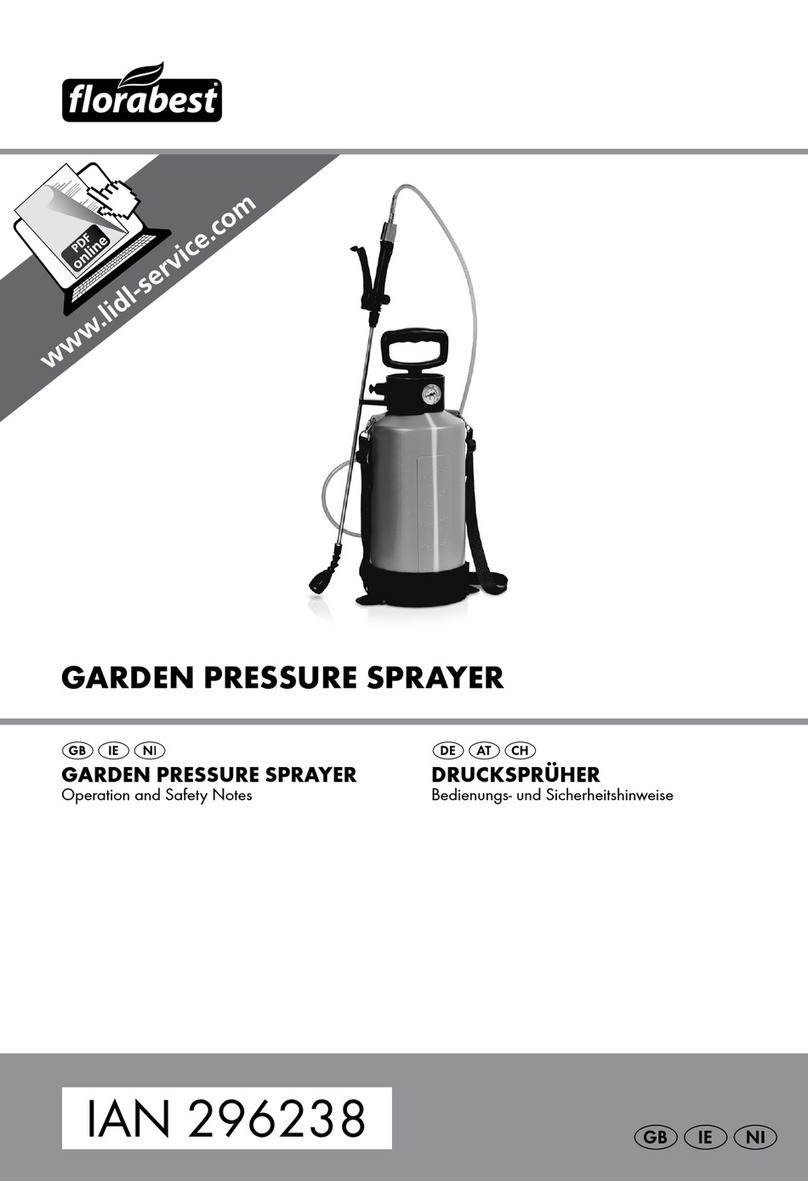

Filling the pressure

sprayer tank (Fig. D)

Note: Before using the product, check to

see that it is in good condition and free of

defects.

Press the pump handle 1downwards

and turn it anticlockwise.

Note: Before you open the tank, pull

the safety valve 3upwards to release

any residual pressure still present in the

container 5.

Draw the pump 2out of the container

5.

Now fill the tank. Ensure that the use of

the pesticide, liquid fertiliser or cleaning

agent is permitted in your country and

that it is compatible with your pressure

sprayer.

Note: Fill the tank with only the

amount of liquid that you actually need

for that particular spraying session (not

more than 5l).

Place the pump 2back into the con-

tainer 5and turn the pump handle 1

clockwise as far as it will go.

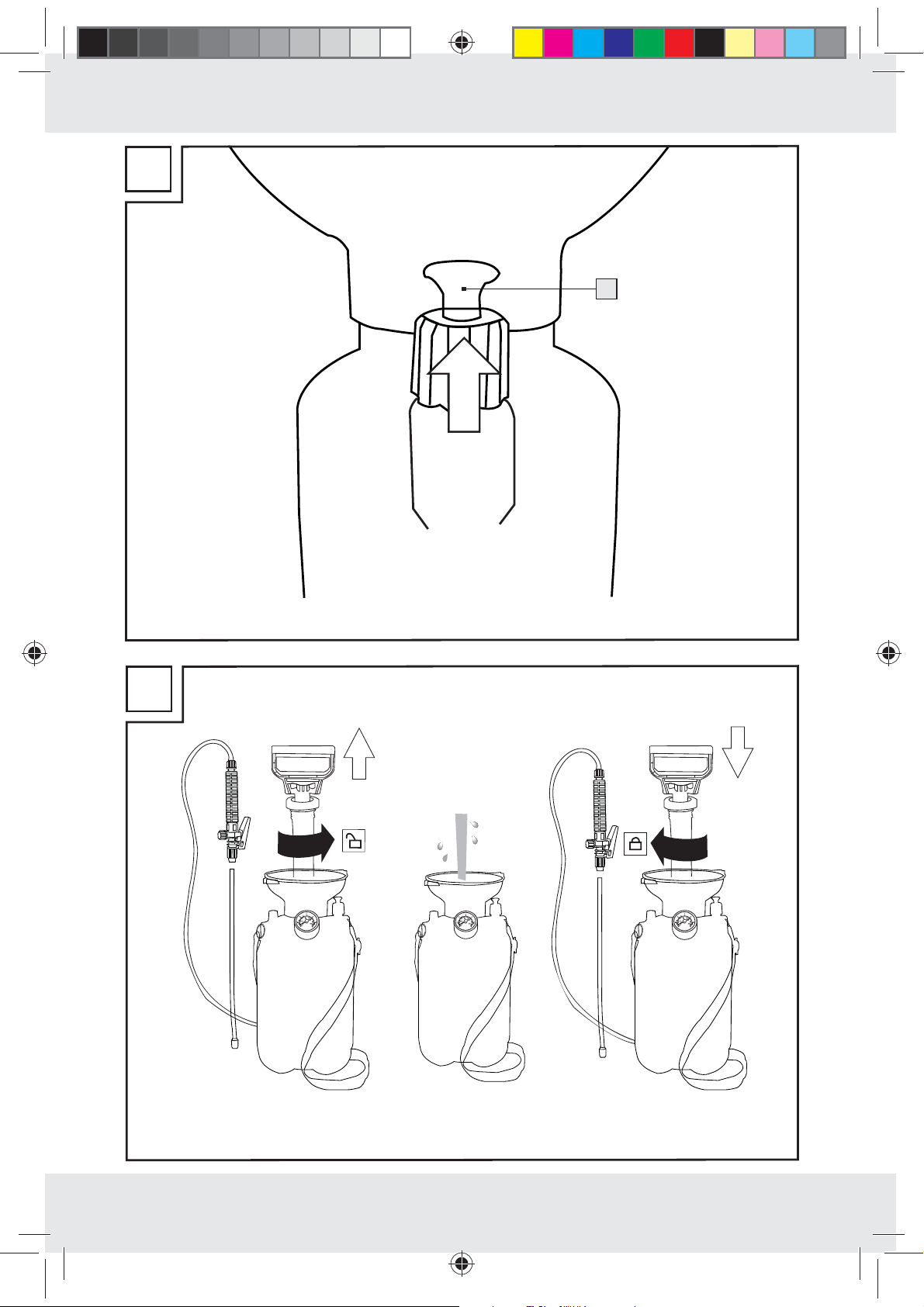

Building up the operating

pressure

Move the pump handle 1up and down

until the pressure sprayer has been

pumped up to a pressure not exceeding

the maximum permissible operating

pressure of 2.5 bar. To ensure this value

is not exceeded, monitor the pressure

gauge 4during the pumping process.

Note: If the pressure of the air in the

container 5exceeds 2.5bar, the pres-

sure is automatically released through

the safety valve 3.