Operation Manual EMGZ309

07.08.2017 2

Table of contents

1 Safety Instructions ..................................................................................... 3

1.1 Description conditions 3

1.2 List of safety instructions 3

2 System Description ................................................................................... 4

2.1 Functional description 4

2.2 Block Diagram 4

3 Quick Installation Guide ............................................................................ 5

3.1 Preparations for Set-up 5

3.2 Installation Procedure 5

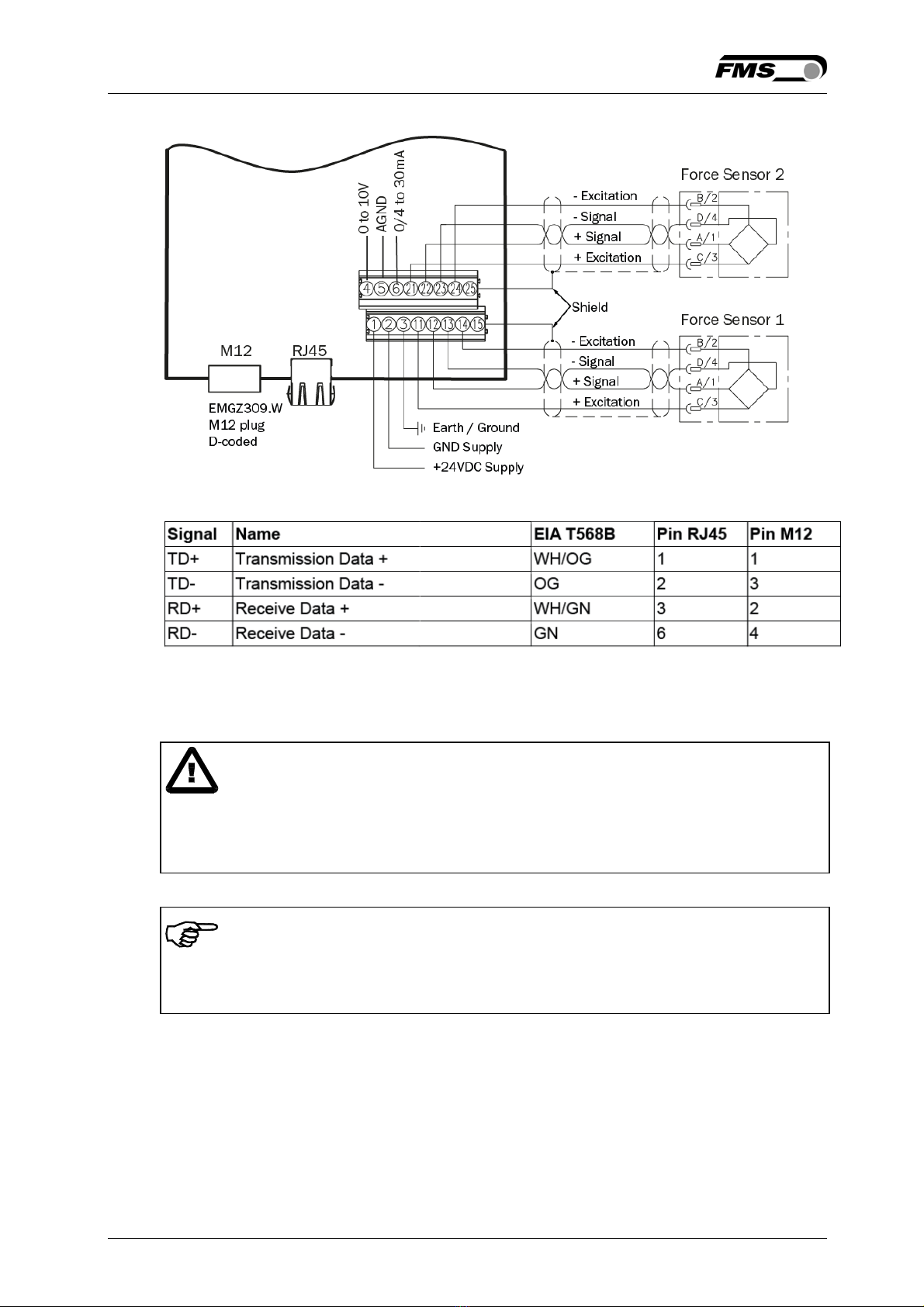

3.3 Installation and wiring 5

3.4 Mounting the Force Sensors 6

3.5 Wiring the Amplifier 6

4 Configuring the Amplifier ......................................................................... 8

4.1 Power up the EMGZ 309 8

4.2 Operating Panel 8

4.3 Change the Measuring Units 9

4.4 Change the Device Mode 9

4.5 Offset Compensation 9

4.6 Offset Compensation over the Operating Panel 10

4.7 Calibration 10

4.8 Calibration over the Operating Panel 11

4.9 Analytic Calibration Method) 12

5 Operation .................................................................................................. 14

5.1 Operating the EMGZ309 over the Operating Panel 14

5.2 Display Value Selection State 15

5.3 Displaying of Overload, Over and Underflow 15

6 Parameterization over the Operating Panel ......................................... 16

6.1 Reset to Default Parameter Set 18

6.2 Parameter List 19

6.3 Description of Parameters 20

7 Parameter Setting via a PC .................................................................... 25

7.1 Parameterization in an Ethernet Network via Web Browser 26

7.2 Offset Compensation via the Web Browser 30

7.3 Calibration via the Web Browser 30

7.4 Connecting the EMGZ309 Amplifier with a PC (Peer-to-Peer) 32

8 Dimensions .............................................................................................. 35

9 Technical Specification ........................................................................... 37