Operating manual EMGZ300

2

1Safety Instructions

1.1 Description conditions

a) High danger of health injury or loss of life

Danger

This symbol refers to high risk for persons to get health injury or loss life. It has to be

followed strictly.

b) Risk of damage of machines

Caution

This symbol refers to informations, that, if ignored, could cause heavy mecanical damage.

This warning has to be followed absolutely.

c) Note for proper function

Note

This symbol refers to an important information about proper use. If not followed, malfunction

can be the result.

1.2 List of safety instructions

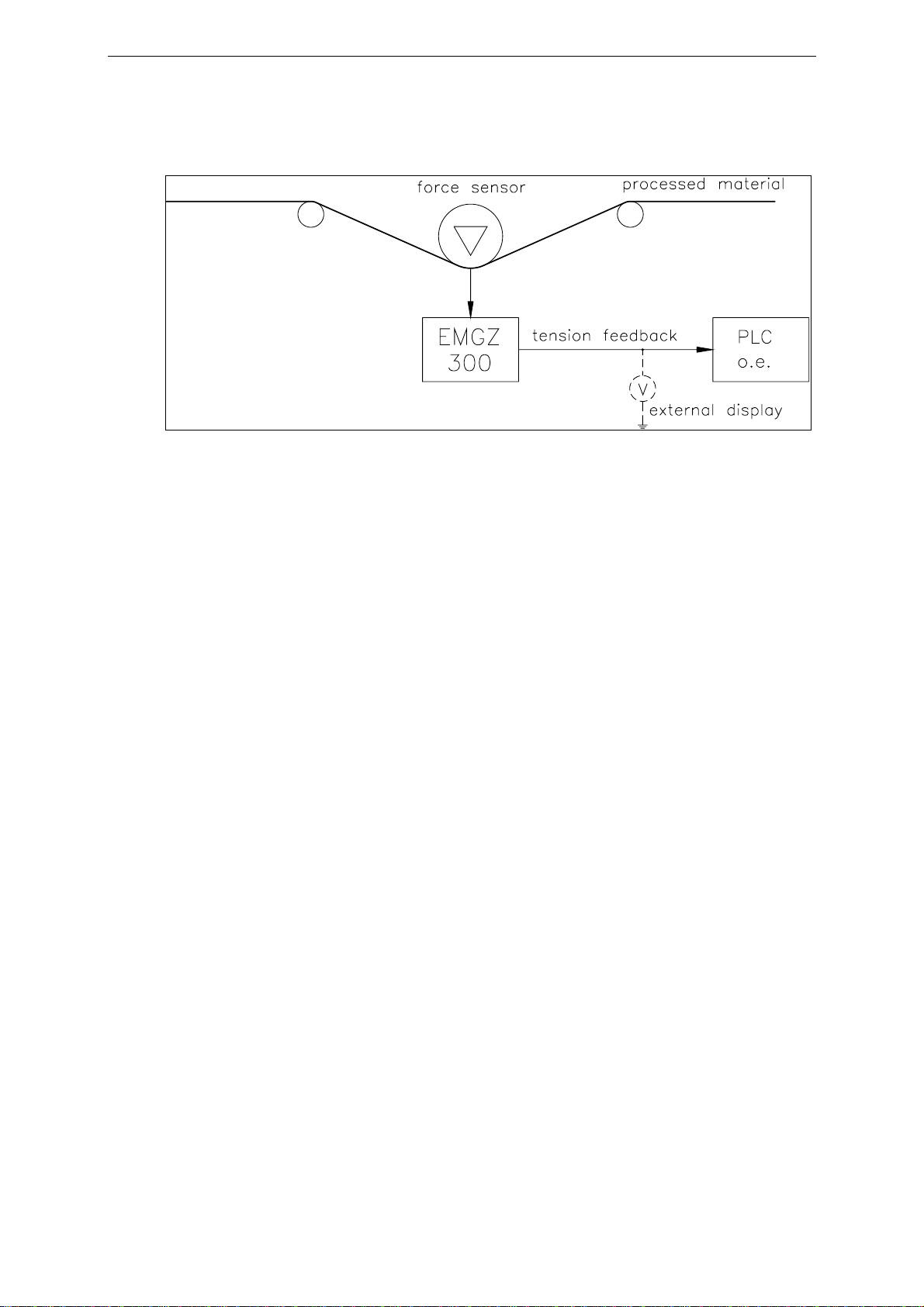

Proper function of the Tension Measuring Amplifier is only guaranteed with the

recommended application of the components. In case of other arrangement, heavy

malfunction can be the result. Therefore, the installation instructions on the following

pages must be followed strictly.

Local installation regulations are to preserve safety of electric equipment. They are not

taken into consideration by this operating manual. However, they have to be followed

strictly.

Improper handling may damage the fragile electronic equipment! Don’t use rough tools

as screwdrivers or pliers! Touch earthed metal part to discharge static electricity before

touching the electronic unit!

Bad earth connection may cause electric shock to persons, malfunction of the total system

or damage of the electronic unit! It is vital to ensure that proper earth connection is done.

Improper mounting may damage the hybride module! The black mark on the hybride

module must match to the edge shown on the printed circuit board. Avoid static

electricity!

The thin ceramic plate of the hybride module is very sensitive. Breaking hazard! Avoid

high forces while mounting! Do not unmount modules once fitted!