Operating Manual EMGZ411

5

4 System description

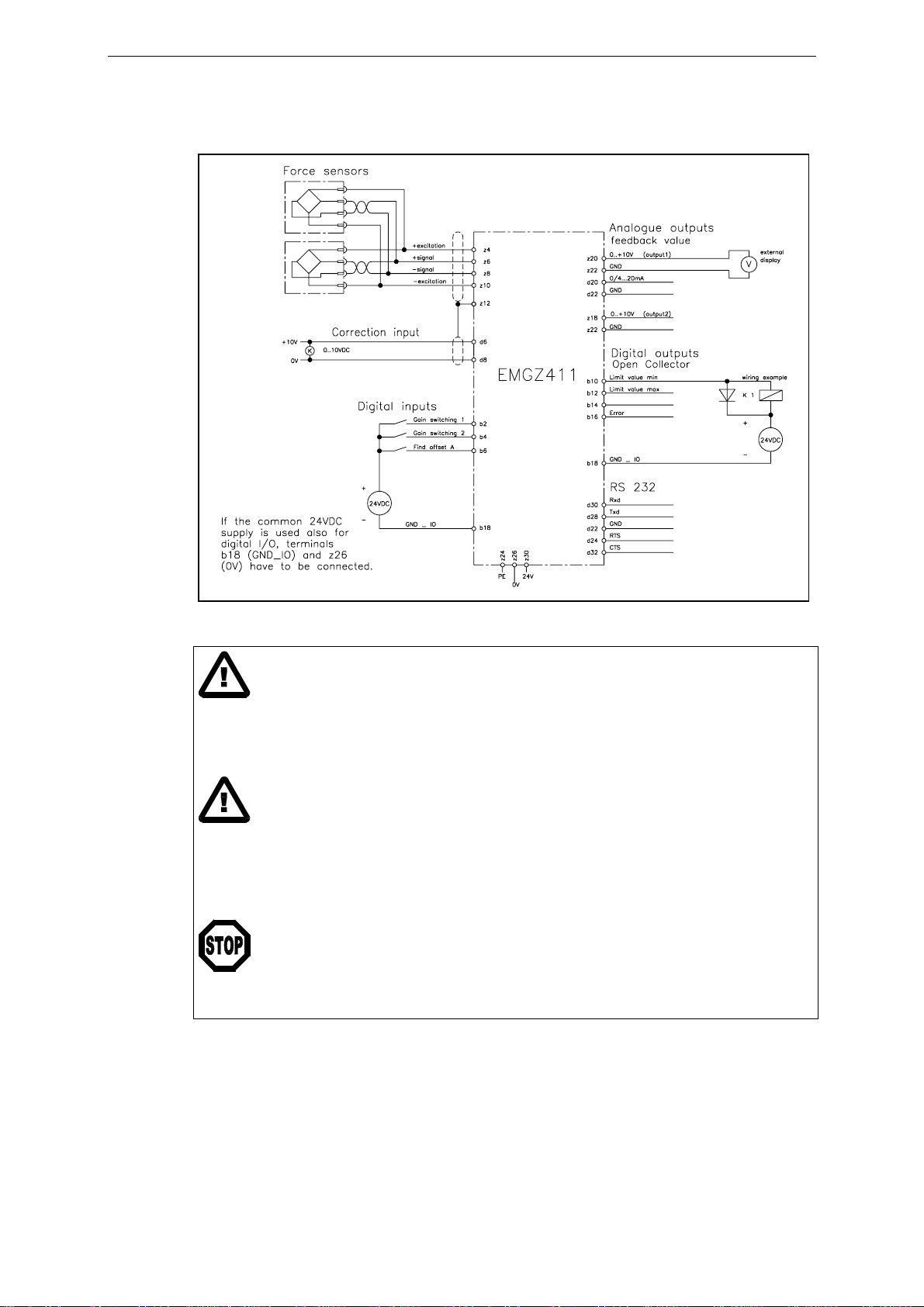

fig. 1: Basic structure of the EMGZ411 tension measuring amplifier E411002e

4.1 Functional description

The force sensors measure the tension force in the material and transmit the measuring

value as a mV signal to the electronic unit EMGZ411. The electronic unit amplifies the

mV signal depending on configuration. The resulting feedback value is shown in the

display in [N]. In addition, the feedback value is provided at the analogue outputs and can

be evaluated by an analogue instrument, a PLC or equivalent devices.

4.2 Force sensors

The force sensors are based on the flexion beam principle. The flexion is measured by

strain gauges and transmitted to the electronic unit as mV signal. Due to the wheatstone

wiring of the strain gauges, the measured value is according also to the power supply. So,

the force sensors are supplied from the EMGZ411 by a very accurate power supply.

4.3 Electronic unit EMGZ411

Common

The electronic unit contains a microprocessor to handle all calculations and

communications, the highly accurate sensor power supply and the signal amplifier for the

measuring value. As operation interface it provides 4 keys, 4 LED’s and a 2x16

characters display in the front of the electronic unit. All inputs are saved in an EEPROM.

The electronic unit has no jumpers or trimmers to keep most accurate long-time and

temperature stability.

There can be connected one or two force sensors to the electronic unit.

Strain gauge amplifier

The strain gauge amplifier provides the highly accurate 4V power supply. A highly

accurate, fixed difference amplifier rises the mV signal up to 10V. This signal will be fed

to the A/D converter. The microprocessor then does all application-specific calculations

with the digitized measuring value (such as offset, gain, low-pass filter, limit switches,

etc).

Using digital inputs, the amplifier can be switched easily between 3 different gain

parameters (for ex. to process different operating conditions). There is no reconfiguration

required to switch the gain parameters.

If a measuring point has a varying wrap angle or other non-linear measuring values, gain

may be adjusted using a linear or a cosine correction.