Operating Instructions EMGZ492.PNET

05.10.2018 2

1 Table of Contents

1 TABLE OF CONTENTS ............................................................................................................................. 2

2 SAFETY INFORMATION ........................................................................................................................... 4

2.1 Presentation of Safety Information ..................................................................................................... 4

2.1.1 Danger that Could Result in Minor or Moderate Injuries ............................................................... 4

2.1.2 Note Regarding Proper Function ................................................................................................... 4

2.2 General Safety Information ................................................................................................................ 5

3 PRODUCT DESCRIPTION ........................................................................................................................ 6

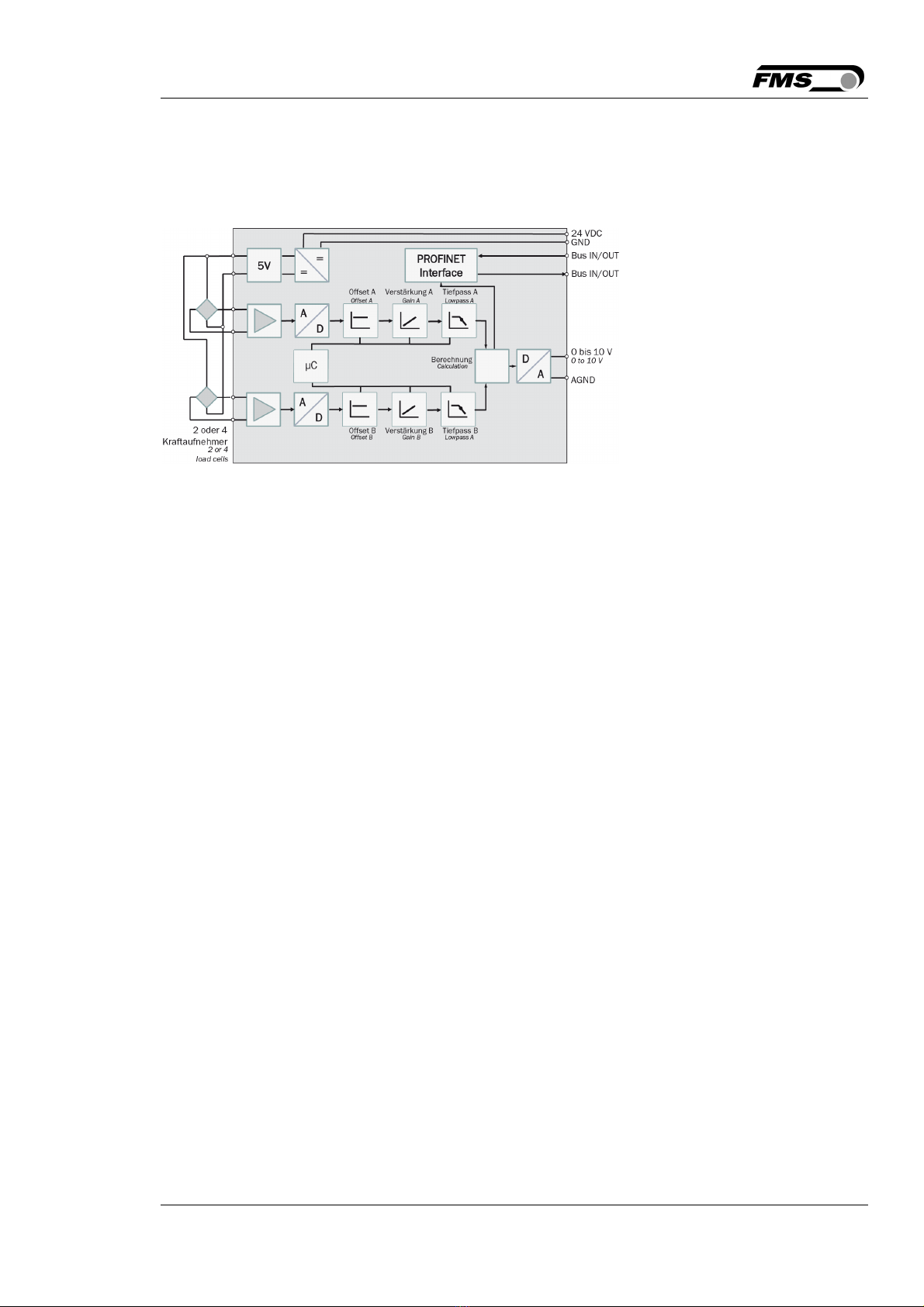

3.1 Block Diagram .................................................................................................................................... 6

3.2 System Description ............................................................................................................................ 6

3.3 Scope of Delivery ............................................................................................................................... 6

4 QUICK GUIDE/QUICK START .................................................................................................................. 7

4.1 Preparations for Parameterization ..................................................................................................... 7

4.2 Mounting Sequence ........................................................................................................................... 7

4.3 Mounting and Electrical Connections ................................................................................................. 7

4.4 Load Cell Mounting ............................................................................................................................ 8

4.5 Electrical Connections ........................................................................................................................ 8

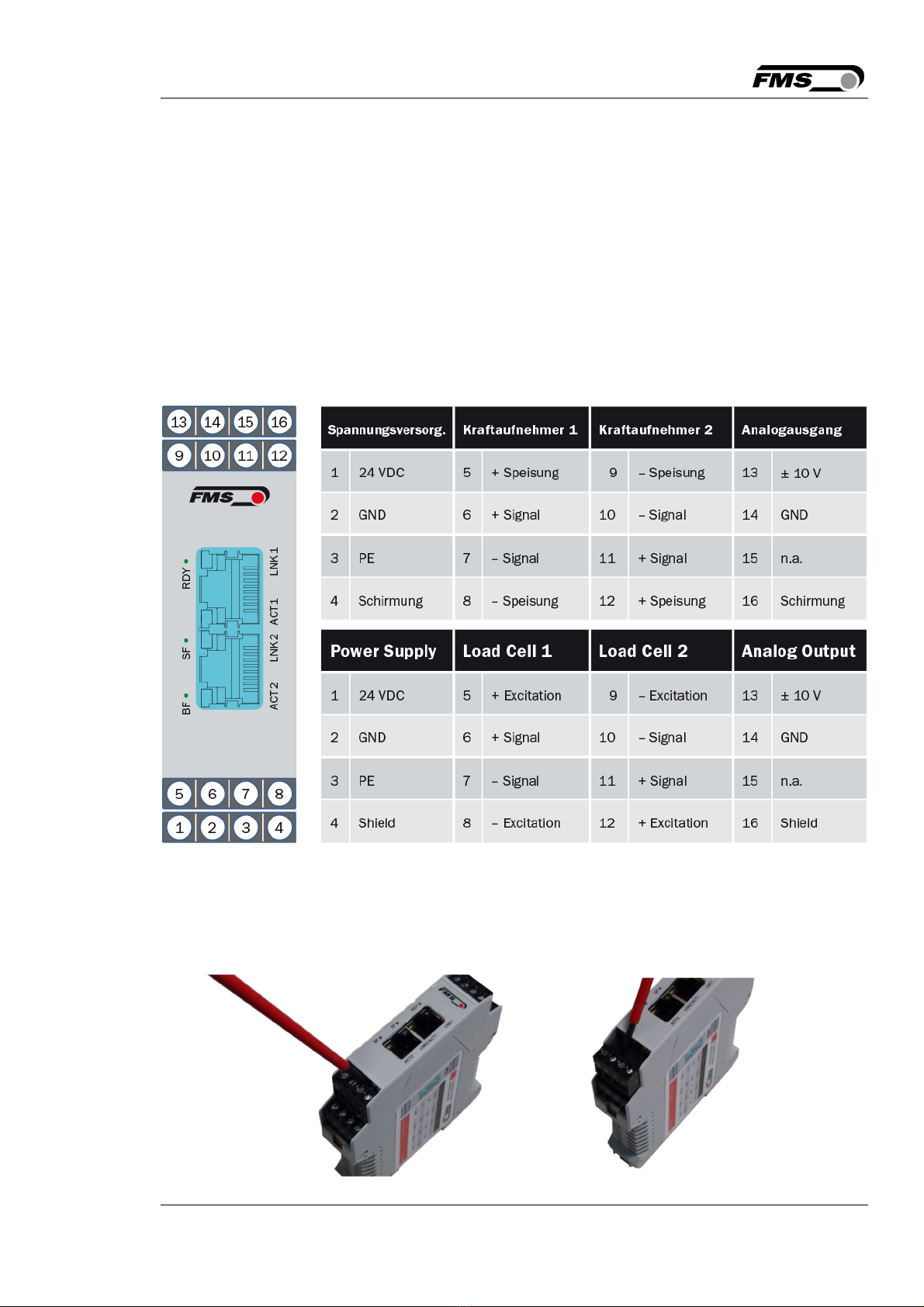

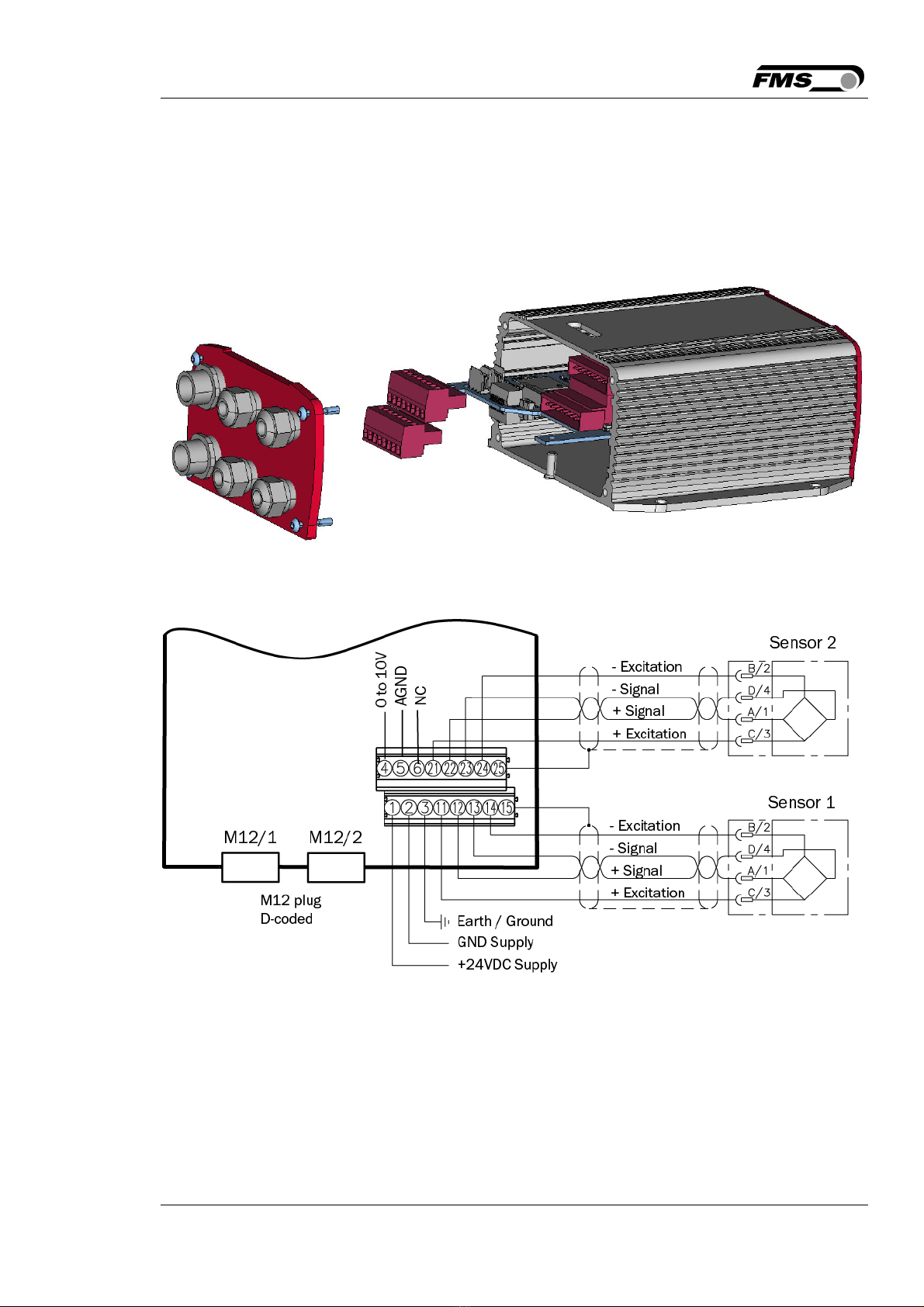

4.5.1 EMGZ492.R.PNET ........................................................................................................................ 8

4.5.2 EMGZ492.W.PNET ....................................................................................................................... 9

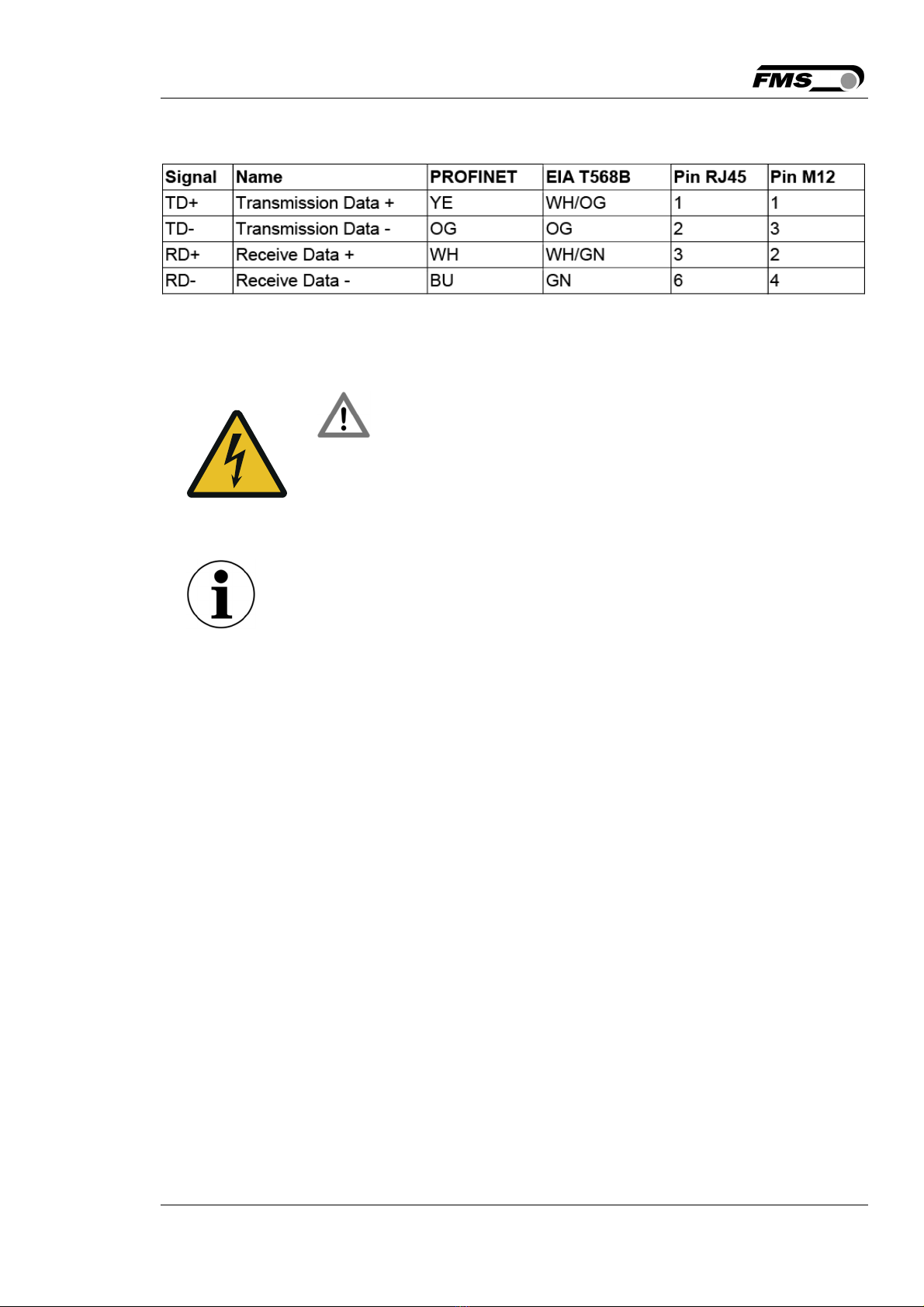

4.5.3 Ethernet Anschlüsse .................................................................................................................... 10

5 CALIBRATION OF THE MEASURING SYSTEM .................................................................................... 11

5.1 Offset Compensation ....................................................................................................................... 11

5.2 Calibration (Adjusting the Gain Factor) ............................................................................................ 11

5.3 Calibration ........................................................................................................................................ 12

5.4 Gain .................................................................................................................................................. 12

5.5 Limit Value Violations ....................................................................................................................... 13

5.5.1 Overload Test .............................................................................................................................. 13

5.5.2 Overflow and Underflow Test ...................................................................................................... 14

5.6 Description of the LEDs ................................................................................................................... 14

6 INTEGRATION INTO THE PROFINET NETWORK ................................................................................ 15

6.1 PROFINET Interface ........................................................................................................................ 15

6.2 TCP/IP Configuration ....................................................................................................................... 15

6.3 System Start ..................................................................................................................................... 15

6.4 Data Exchange ................................................................................................................................. 15

7 CONFIGURATION .................................................................................................................................... 16

7.1 Parameter Description ..................................................................................................................... 16

7.2 Cyclic Data Traffic ............................................................................................................................ 19

7.3 Acyclic Data Traffic .......................................................................................................................... 22

8 PROFINET COMMUNICATION ............................................................................................................... 30

8.1 General Function .............................................................................................................................. 30

8.2 Services and Protocols .................................................................................................................... 30

9 WEB INTERFACE .................................................................................................................................... 31

9.1 Amplifier Access via Web Interface ................................................................................................. 31

9.2 Parameter Settings .......................................................................................................................... 33

9.3 Offset Adjustment and Calibration via Web Browser ....................................................................... 34

9.4 Ethernet Settings .............................................................................................................................. 35

9.5 System Settings ............................................................................................................................... 36