Operating manual EMGZ308

5

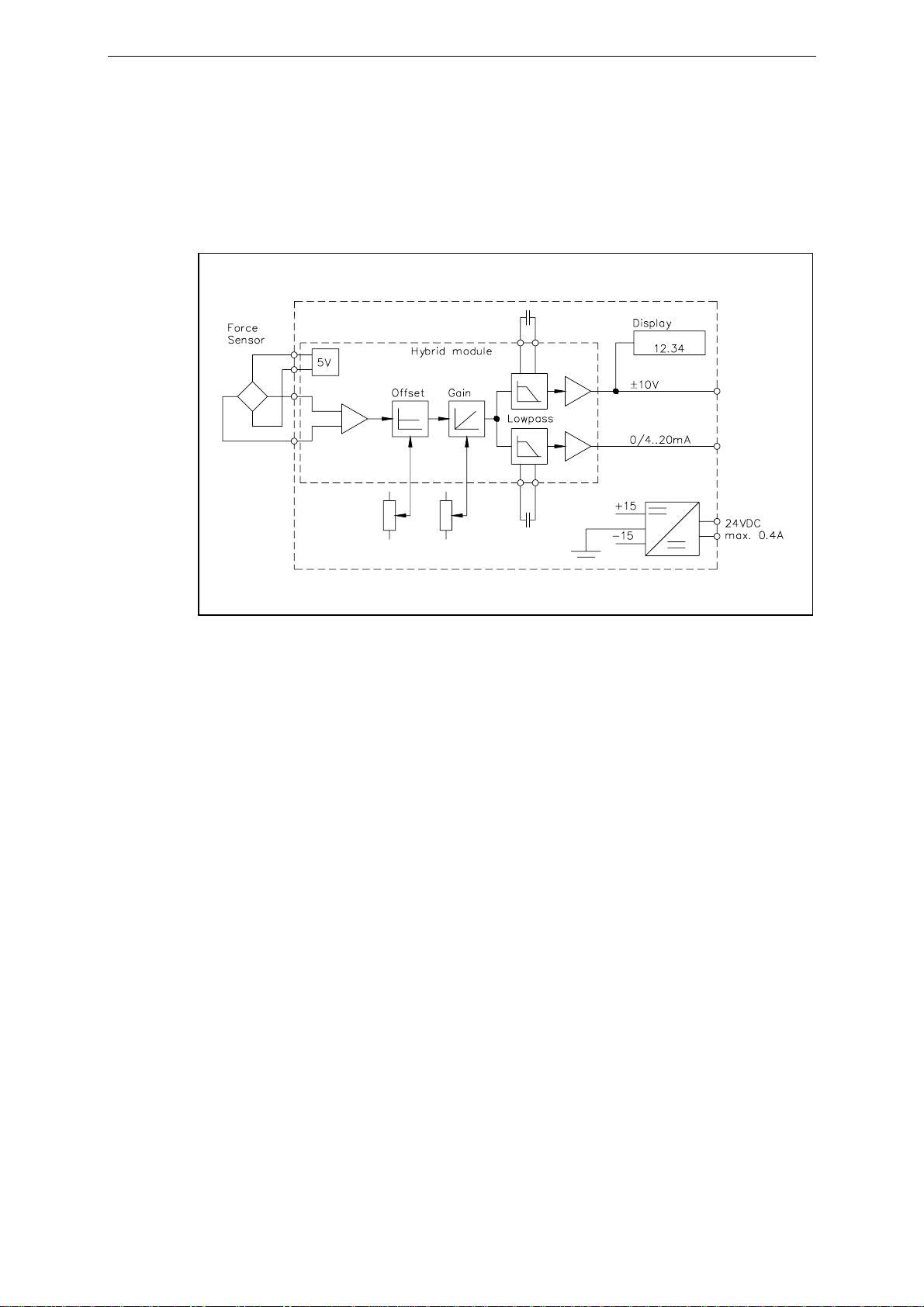

4 System description

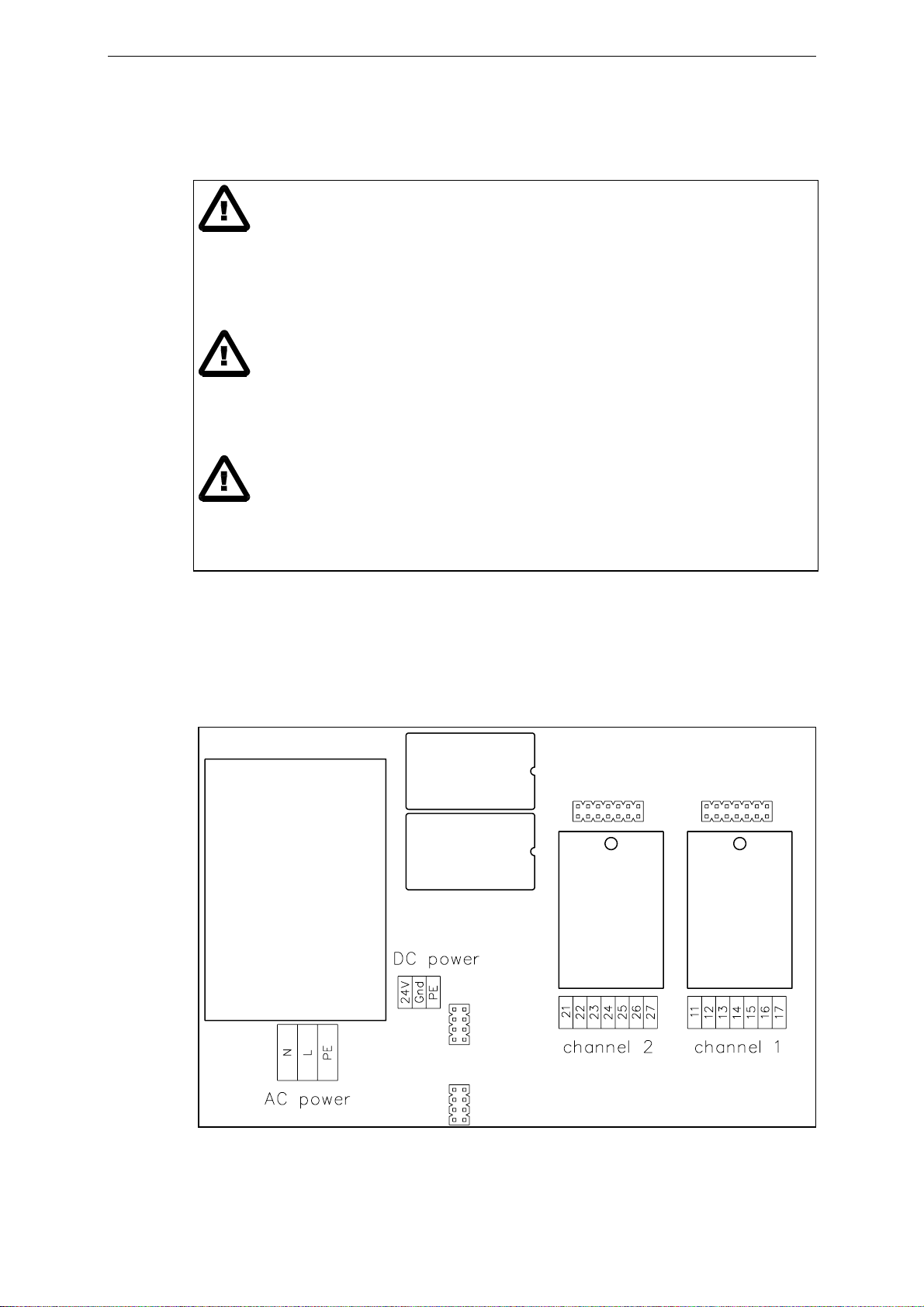

fig. 1: Basic structure of the EMGZ308 Tension Measuring Amplifier (picture shows

single channel version) E308001e

4.1 Functional description

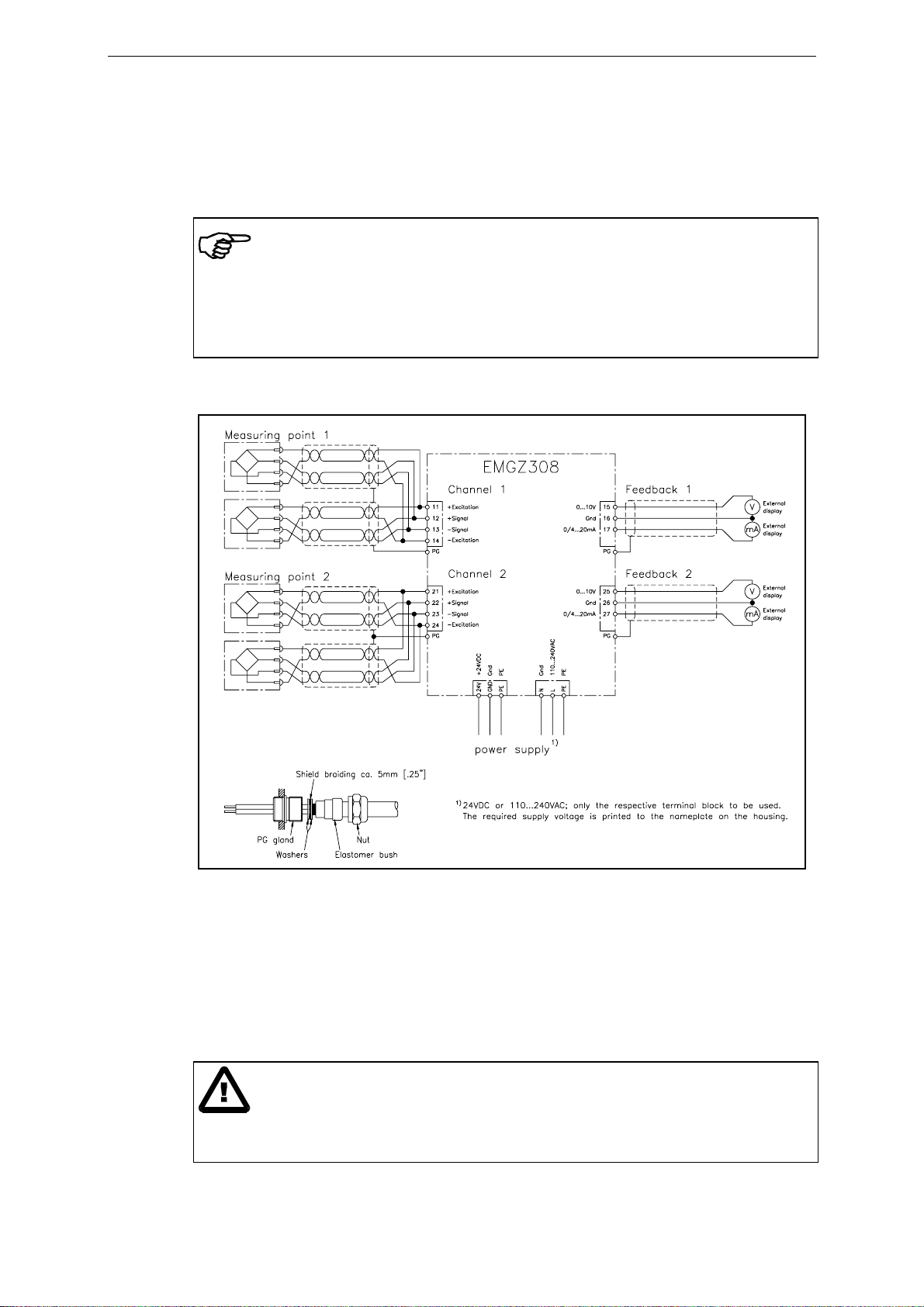

The force sensors measure the tension force in the processed material and transmit the

measuring value as a mV signal to the hybrid module in the measuring amplifier

EMGZ308. The measuring amplifier amplifies the mV signal depending on configuration.

The resulting feedback value can be transmitted to an analog instrument, a PLC or

equivalent devices. In addition, the force value is shown in the integrated digital display.

4.2 Force sensors

The force sensors are based on the flexion beam principle. The flexion is measured by

strain gauges and transmitted to the measuring amplifier as mV signal. Due to the

wheatstone wiring of the strain gauges, the measured value is according also to the power

supply. So, the force sensors are supplied from the EMGZ308 by a very accurate power

supply.

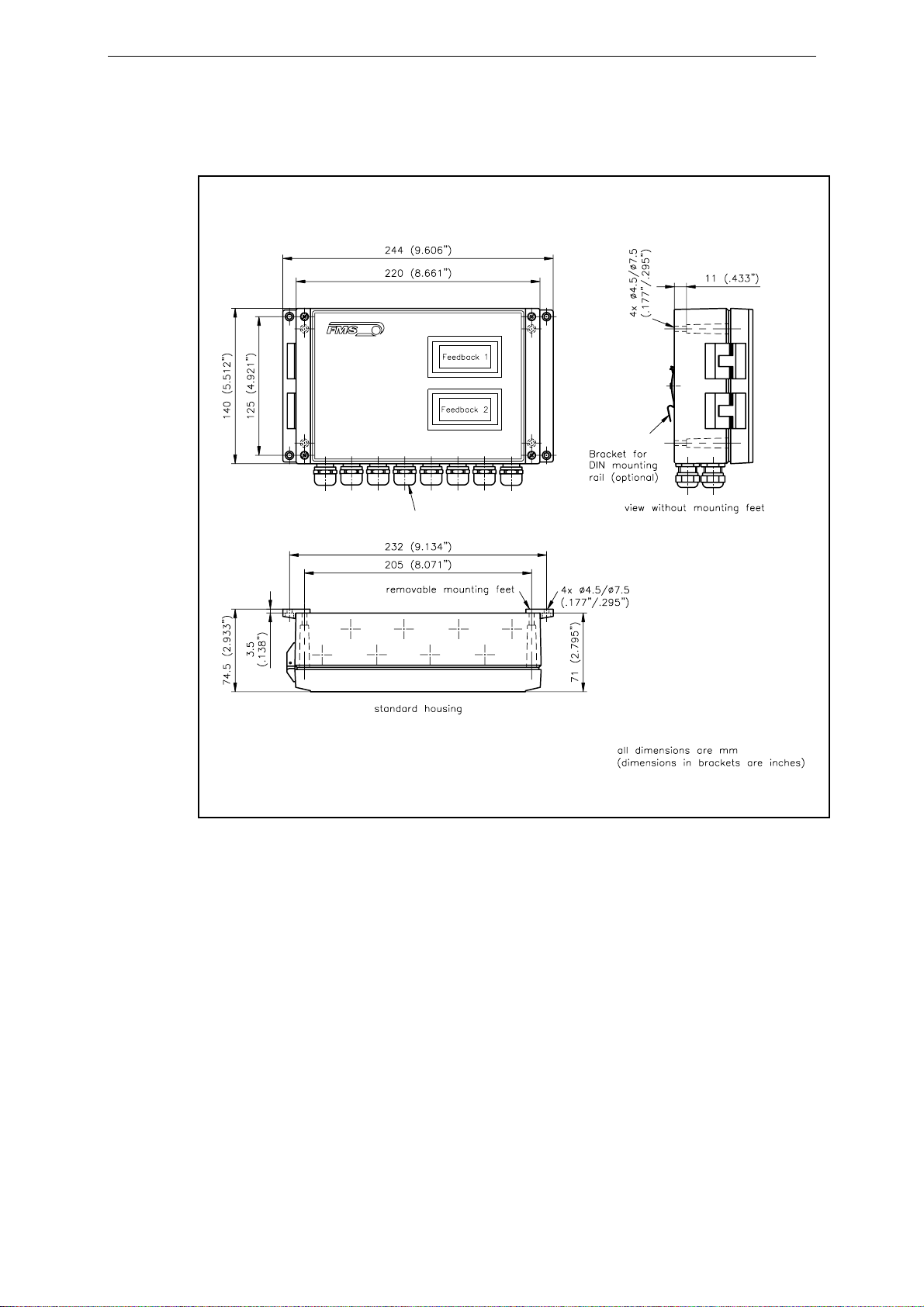

4.3 Measuring amplifier EMGZ308

The EMGZ308 is a single or double channel analog Tension Measuring Amplifier based

on a hybrid circuit per channel. It is delivered in a robust aluminium housing. All

connections are led through glands to screw terminals. There can be connected 1 or 2

force sensors of 350Ωto each channel. The hybrid modules provide the highly accurate

5V power supply and amplify the mV signals of the force sensors to a level of 10V and

20mA. Tension and current output are active the same time. The hybrid technology

ensures both good thermal and electrical characteristics. Measuring circuit and power

supply are galvanic insulated.

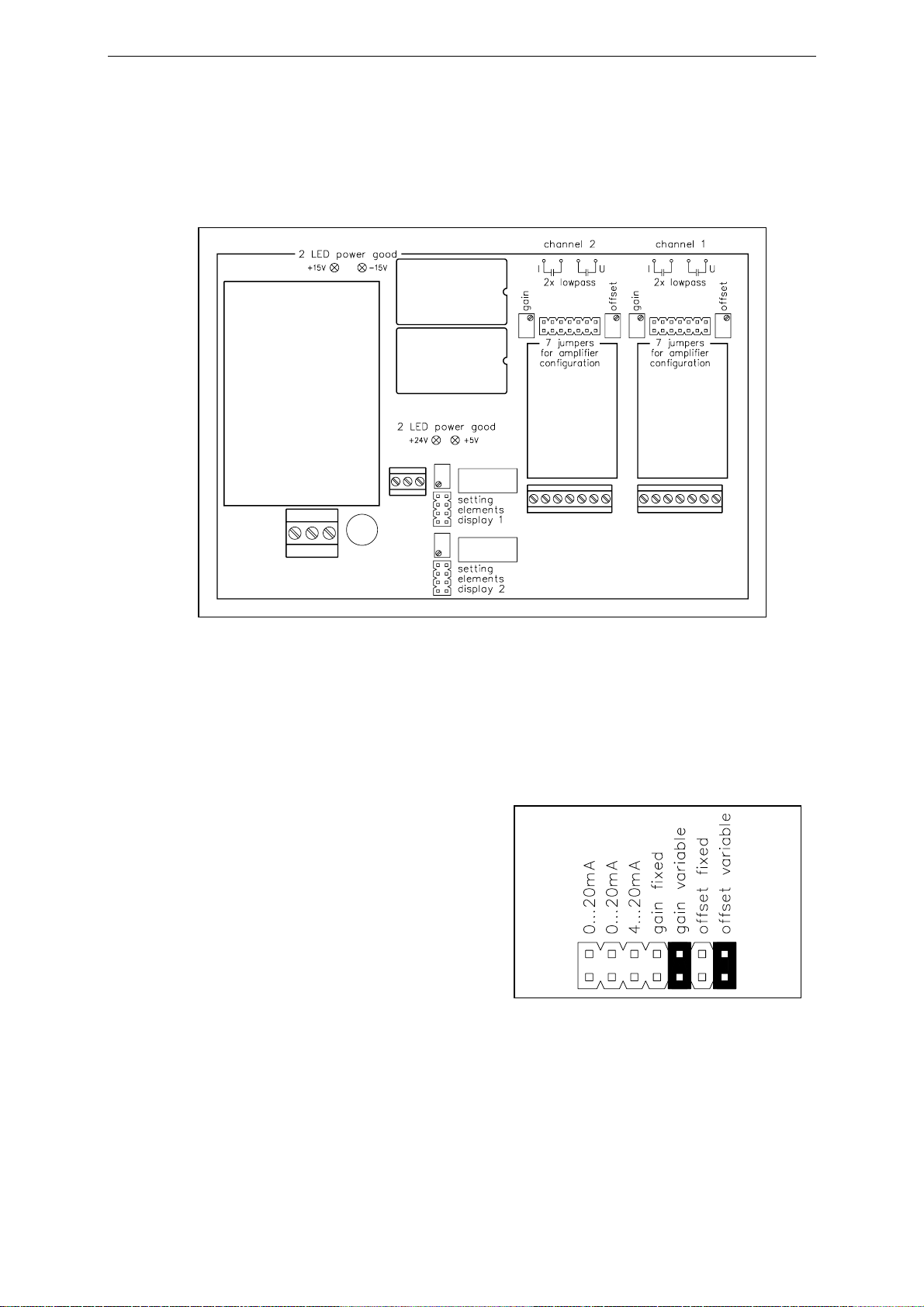

Setting of gain and offset is done by 2 trimmers. For filtering of the signals, non-

polarized capacitors can be soldered.

Infinite adjustment of gain and offset

Setting by trimmers is used to get a standardized output signal (i.e. 10V) from any kind of

sensor signal. This ensures accurate amplifying of the signal and maximum immunity to

any interference of the signal cable.