Operation Manual EMGZ490A

30.08.2019 2

Table of Content

1 Safety Instructions .......................................................................... 4

1.1 Description Conditions ............................................................................................... 4

1.2 List of safety instructions ........................................................................................... 5

2 Product Description ........................................................................ 6

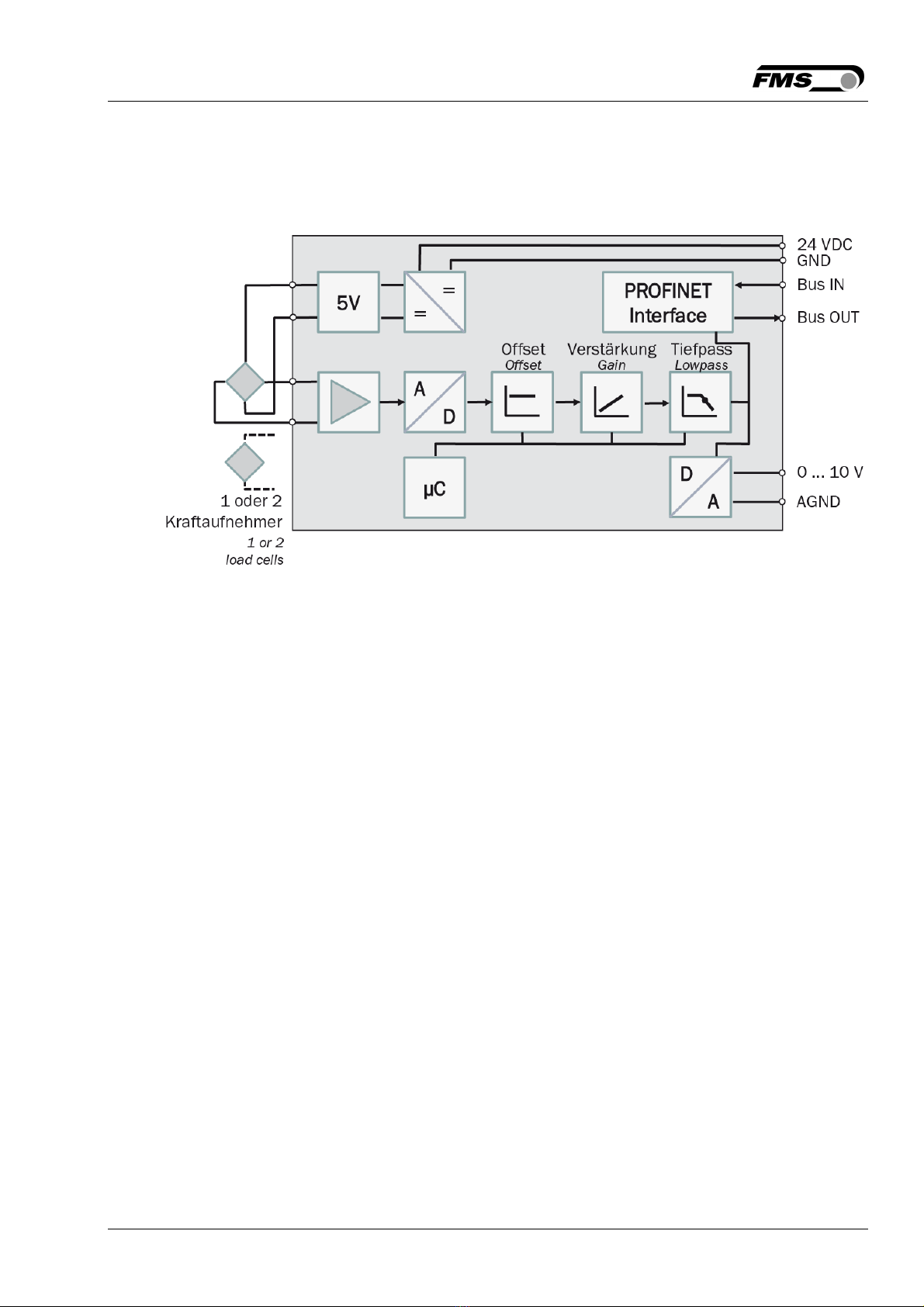

2.1 Block Diagram EMGZ490A ........................................................................................ 6

2.2 System Description EMGZ490A ................................................................................. 6

3 Quick Installation Guide ................................................................. 7

3.1 Preparations for Set-up .............................................................................................. 7

3.2 Installation Procedure ................................................................................................ 7

3.3 Installation and Wiring ............................................................................................... 7

3.4 Mounting the Force Sensors ...................................................................................... 7

3.5 Wiring the Amplifier .................................................................................................... 8

4 Calibration of the Measuring System ........................................... 10

4.1 Offset Compensation ................................................................................................ 10

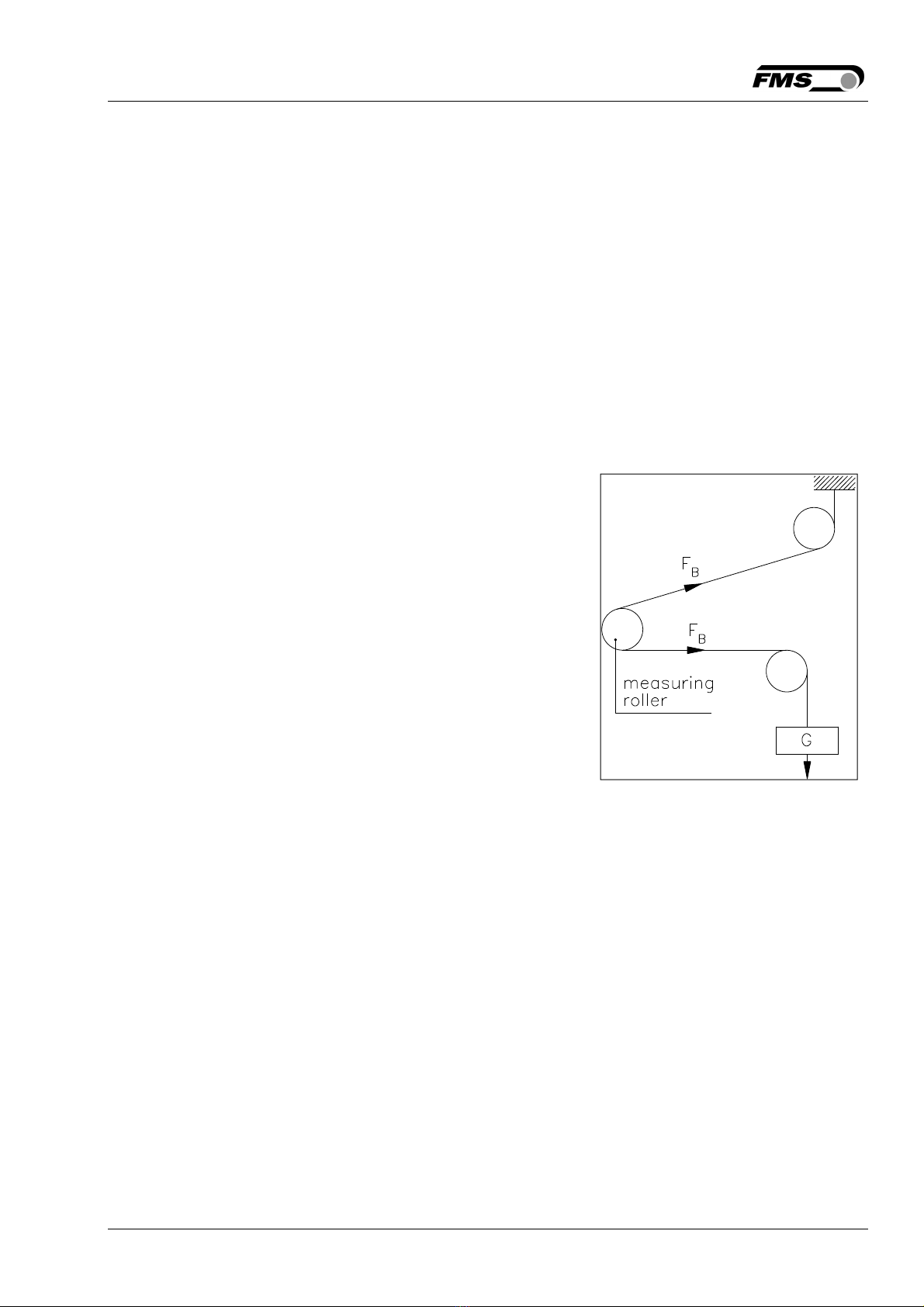

4.2 Calibration ................................................................................................................. 10

4.3 Calibration Procedure ............................................................................................... 11

4.4 Gain ........................................................................................................................... 12

4.5 Limit Violations ......................................................................................................... 13

4.6 Description of Signal-LEDs ....................................................................................... 14

5 Integration in a PROFINET-network .............................................. 14

5.1 PROFINET Interface ................................................................................................. 14

5.2 TCP/IP Configuration ................................................................................................ 15

5.3 System Start-up ........................................................................................................ 15

5.4 Data Exchange .......................................................................................................... 15

6 Configuration ................................................................................ 16

6.1 Description of Parameters ....................................................................................... 16

6.2 Cyclic Data Traffic ..................................................................................................... 18

6.3 Acyclic Data Traffic ................................................................................................... 19

7 PROFINET Communication ........................................................... 21

7.1 General Function ....................................................................................................... 21

7.2 Services and Protocols ............................................................................................. 21

7.3 Limitations ................................................................................................................ 22

7.4 Functional Blocks, Example ..................................................................................... 23

7.5 Data Blocks ............................................................................................................... 24

7.6 Trigger Read-/Write-instructions .............................................................................. 25

7.7 Configuration File GSDML ........................................................................................ 26

7.8 Tools ......................................................................... Fehler! Textmarke nicht definiert.

8 Web Interface ............................................................................... 27

8.1 Access to the Amplifier over a Web Interface ......................................................... 27

8.2 Parameter Setting .................................................................................................... 29