Operating manual EMGZ306A

10

7.3 Configuring the lowpass filter

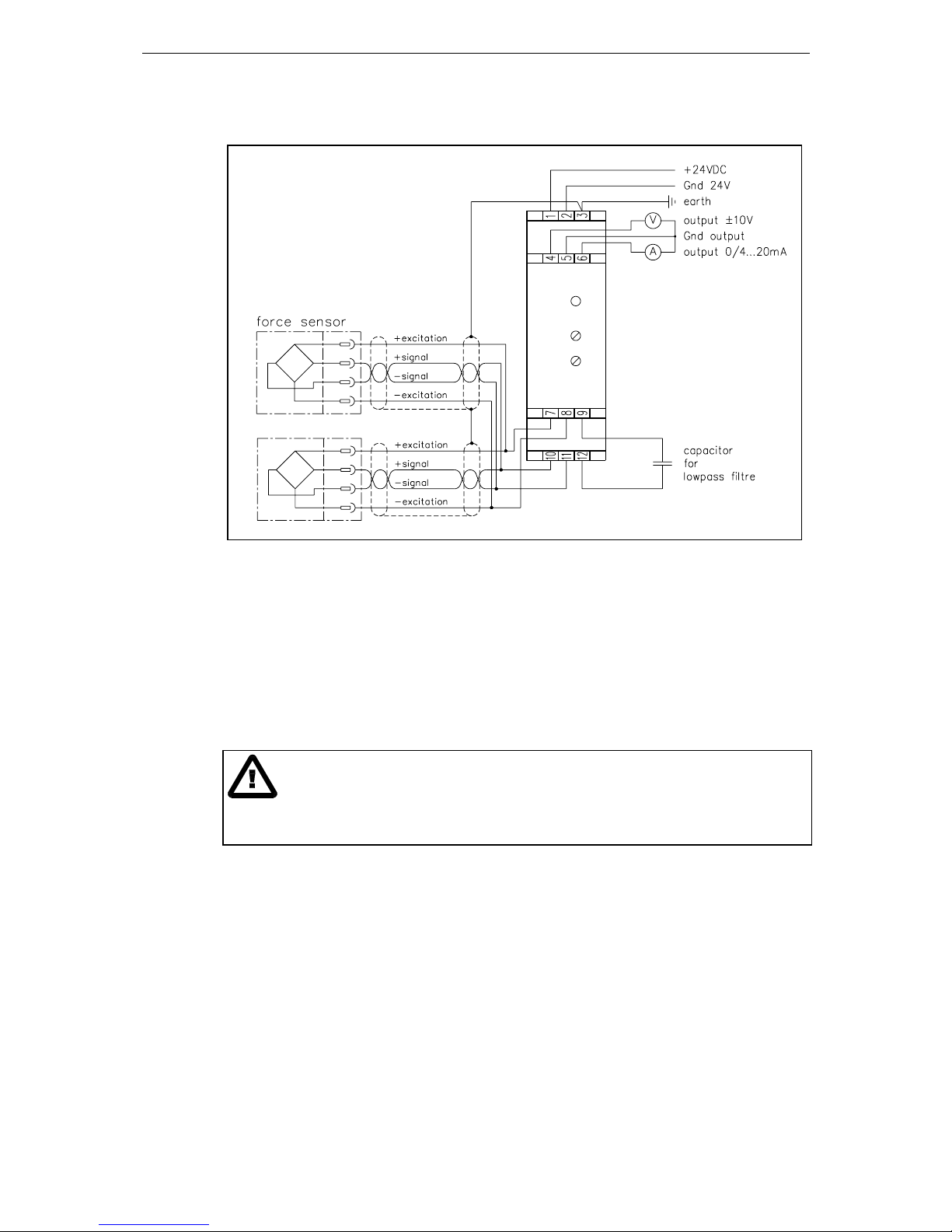

The measuring amplifier provides a lowpass filter. It is used to eliminate faulty signal

variations which may be caused by unbalanced rollers, vibrations of the machine, or

equivalent.

The lowpass filter is effective to both the tension- and the current output. The lower the

cut-off frequency, the more sluggish the output signal will be. The configuration is made

by connecting a non-polarized capacitor to the terminals 9 and 12 (refer to fig. 4). The

capacitor will be determined referring to the following formula resp. list:

Cut-off frequency

[Hz] Capacitor [µF]

1 10

C = 10 / F 2 5

5 2

10 1

C: Capacity [µF] 20 0.5

F: Cut-off frequency [Hz] 50 0.2

100 0.1

200 0.05

500 0.02

1000 0.01

Notice

You must not use electrolytic capacitors because positive and negative signals are

appearing! They would damage the electrolytic capacitor.

7.4 Calibrating the measuring amplifier

• Connect gauge to the tension- resp. current output.

• Connect the first force sensor

• Check, if a positive output signal is appearing when loading the sensor in measuring

direction. If not, exchange the two signal wires of the referring force sensor in the

terminal block (terminals 10 / 11).

• If used, connect the second force sensor.

• Check, if a positive output signal is appearing when loading the sensor in measuring

direction. If not, exchange the two

signal wires of the referring force

sensor in the terminal block (terminals

10 / 11).

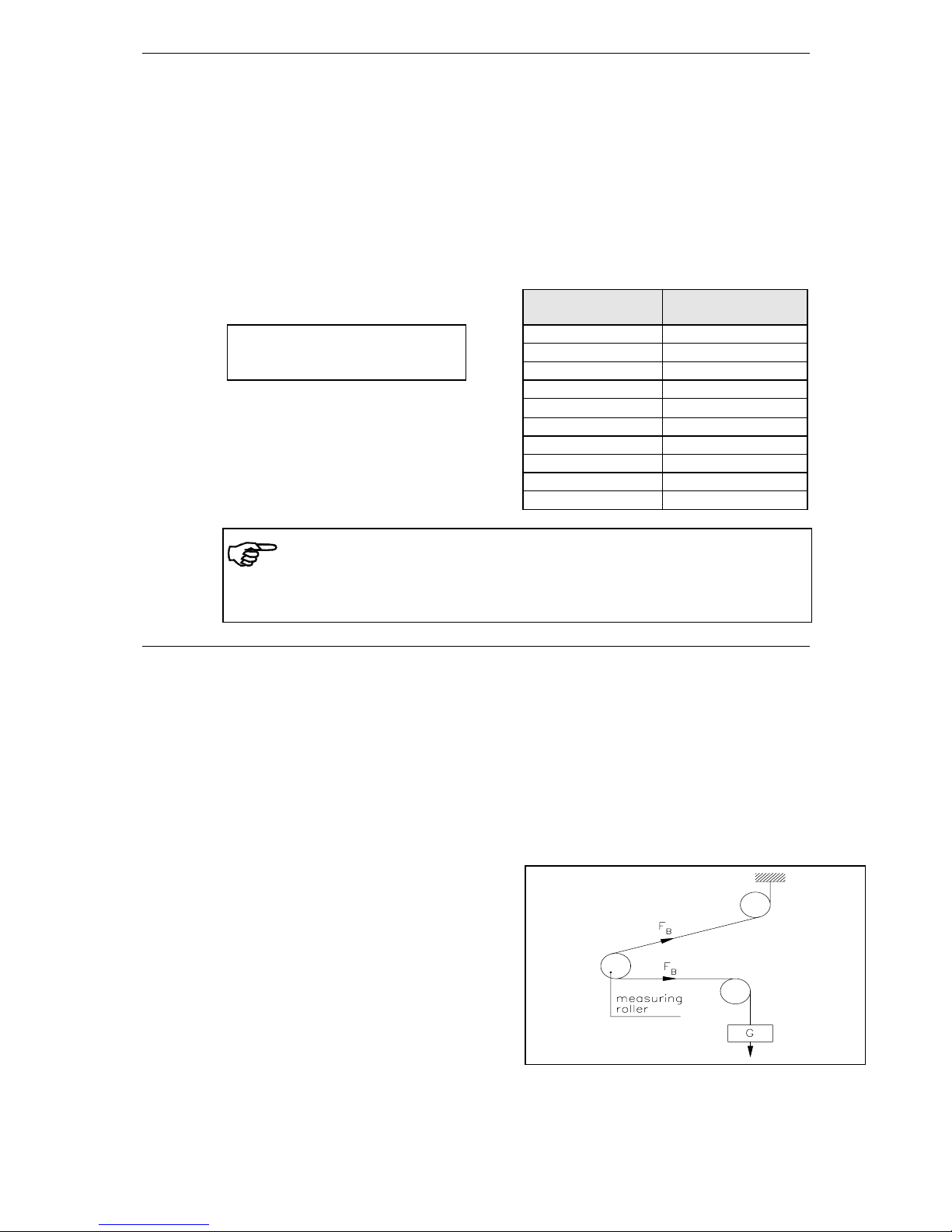

• Insert material or a rope loosely to the

machine.

• Adjust the offset trimmer until the

output value is zero.

• Load material or rope with a defined

weight (fig. 8).

• Adjust the gain trimmer until the

output value shows the needed value

(for ex. 10V corresponding to 500N).

fig. 8: Calibrating the measuring amplifier