Operating Manual EMGZ470A/472A

3

Table of Contents

1Safety Instructions ....................................................................................2

1.1 Warnings 2

1.2 List of Safety Instructions 2

2Definitions..................................................................................................4

3System Components..................................................................................4

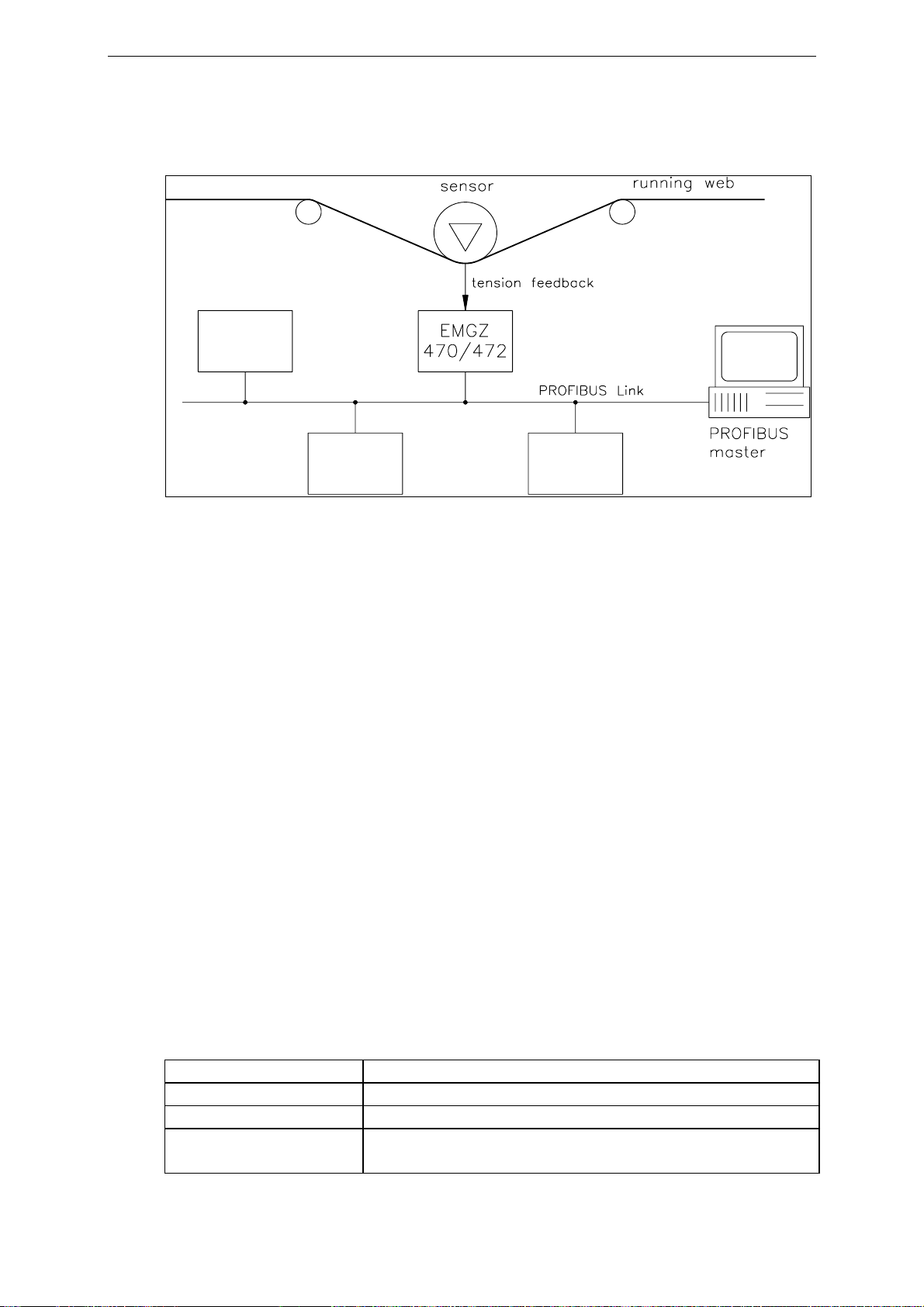

4System Description....................................................................................5

4.1 Functional Description 5

4.2 Force Sensor 5

4.3 Electronic Unit EMGZ470A.W/472A.W 5

4.4 Block Diagram 6

5Quick Installation Guide..........................................................................7

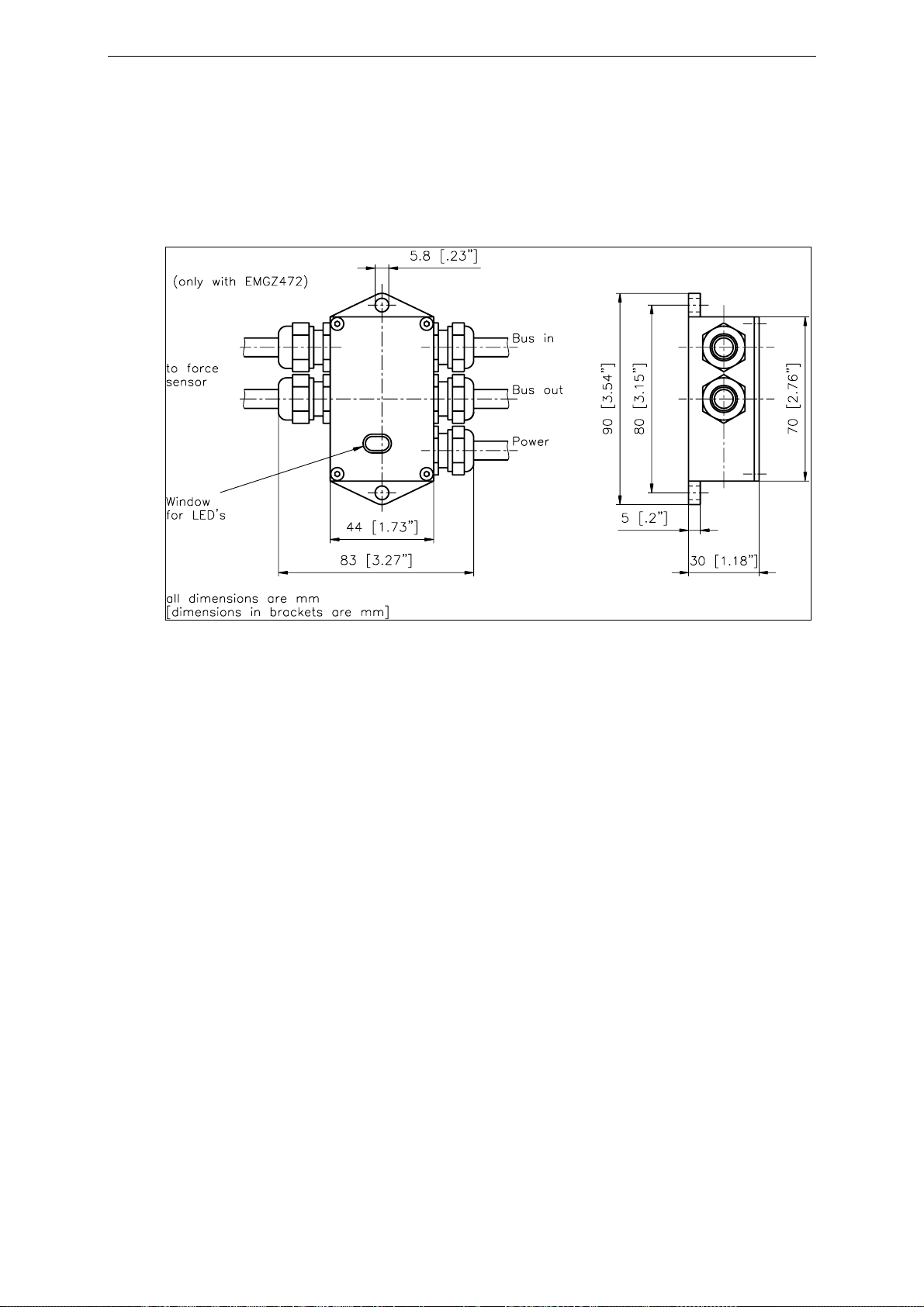

6Dimensions.................................................................................................8

6.1 Dimensions of Offset Version (EMGZ470A.W) 8

6.2 Dimensions Double-Channel Version (EMGZ470/472A.W.D) 9

7Installation and Wiring ..........................................................................10

7.1 Mounting the Force Sensors 10

7.2 Mounting of the Measuring Amplifier 10

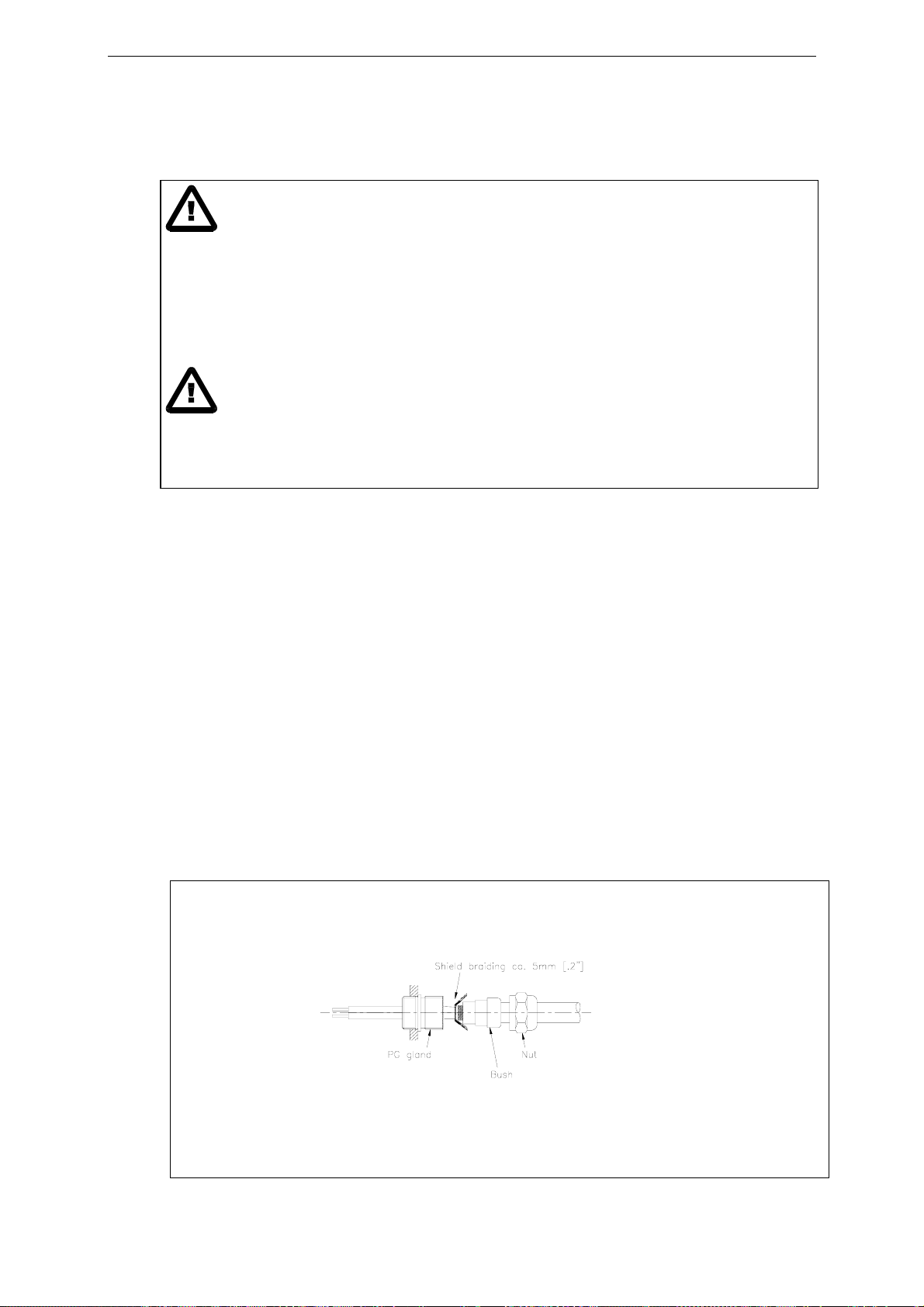

7.3 Wiring from Measuring Amplifier to Force Sensor 10

7.4 Wiring of Power Supply and PROFIBUS Data Cable 11

7.5 Wiring Diagram 12

7.6 Setting the PROFIBUS Address 13

8PROFIBUS Interface Description.........................................................14

8.1 GSD File 14

8.2 EMGZ470A.W/472A.W DP Slave Functional Description 14

8.3 Initial Parameters 14

8.4 Configuration 15

8.5 Process Data 16

9Calibrating the Measuring Amplifier ...................................................18

9.1 Simulating Method, Calibration within the PLC 18

9.2 Simulating Method, Calibration using Initial Parameters 19

9.3 Simulating Method, Calibration using Control Byte (Module 1 only) 19

9.4 Mathematical Method (Module 1 only) 20

9.5 Configuring the Lowpass Filter 21

10 Trouble Shooting.....................................................................................22

11 Technical Data EMGZ470A.W/472A.W...............................................23