Operating Manual EMGZ621A

3

Table of Contents

1Safety Instructions ....................................................................................2

1.1 Description conditions 2

1.2 List of safety instructions 2

2Definitions..................................................................................................4

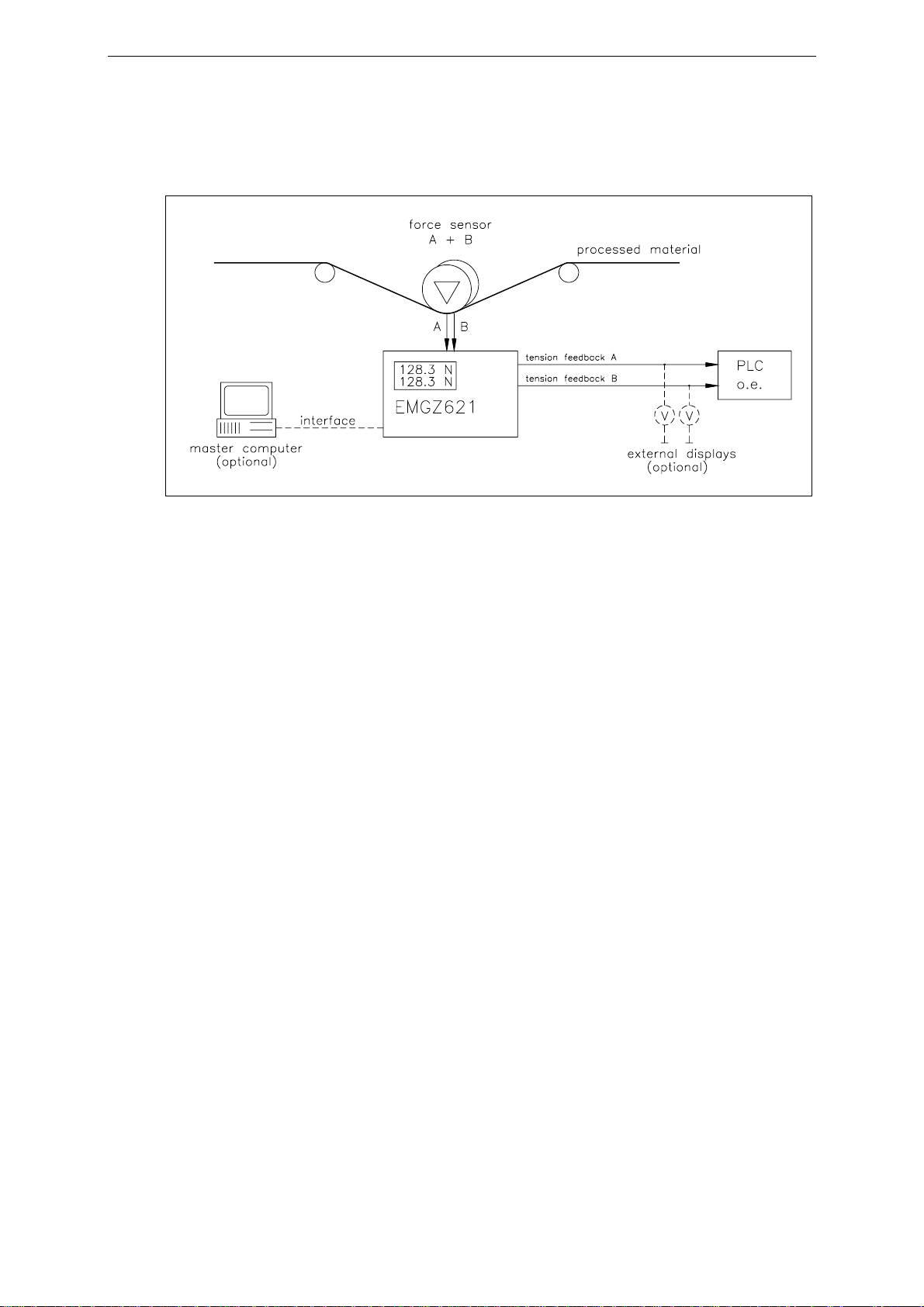

3System Components..................................................................................4

4System Description....................................................................................5

4.1 Functional Description 5

4.2 Force Sensors 5

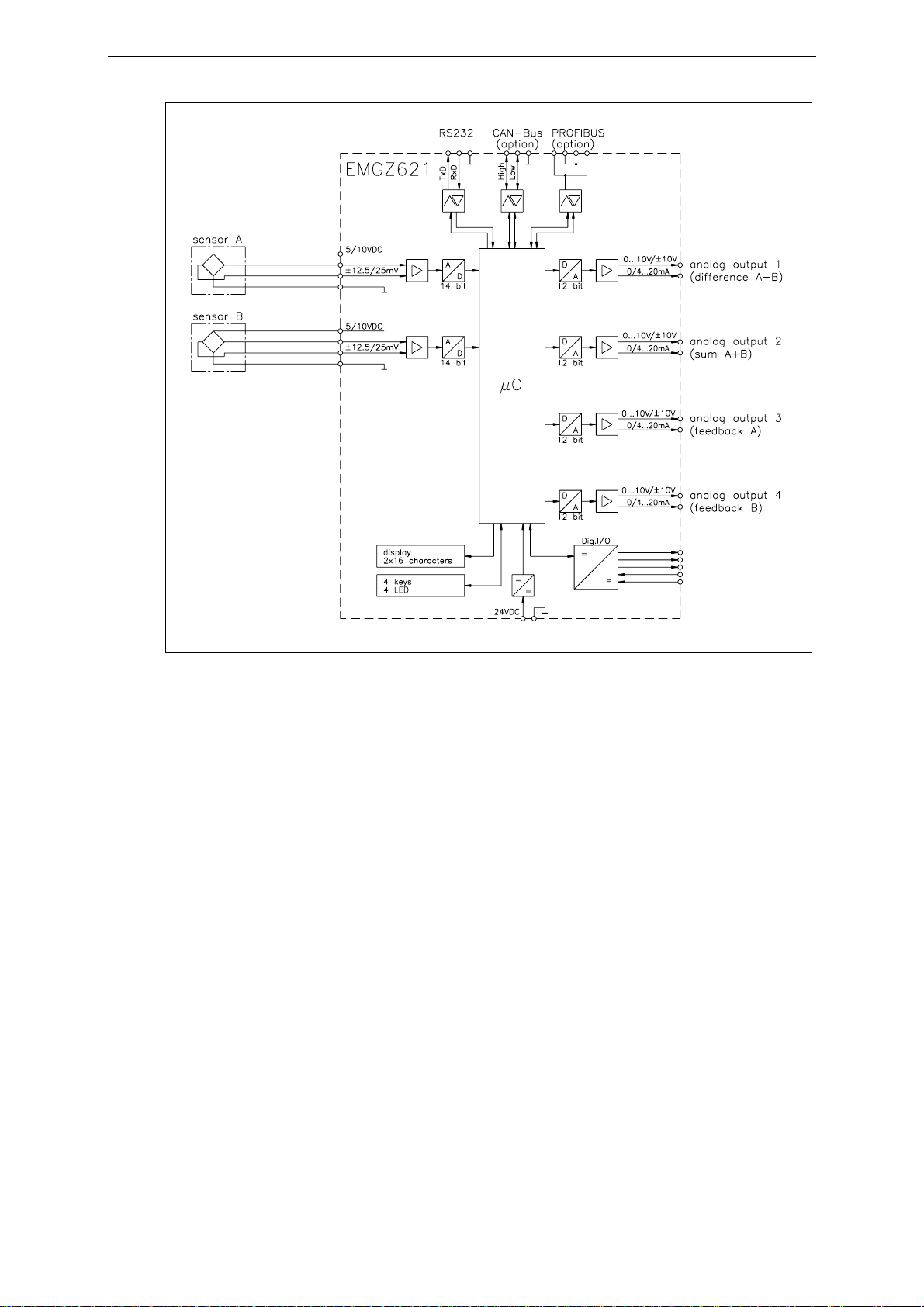

4.3 Electronic Units EMGZ621A 6

5Quick Installation Guide..........................................................................7

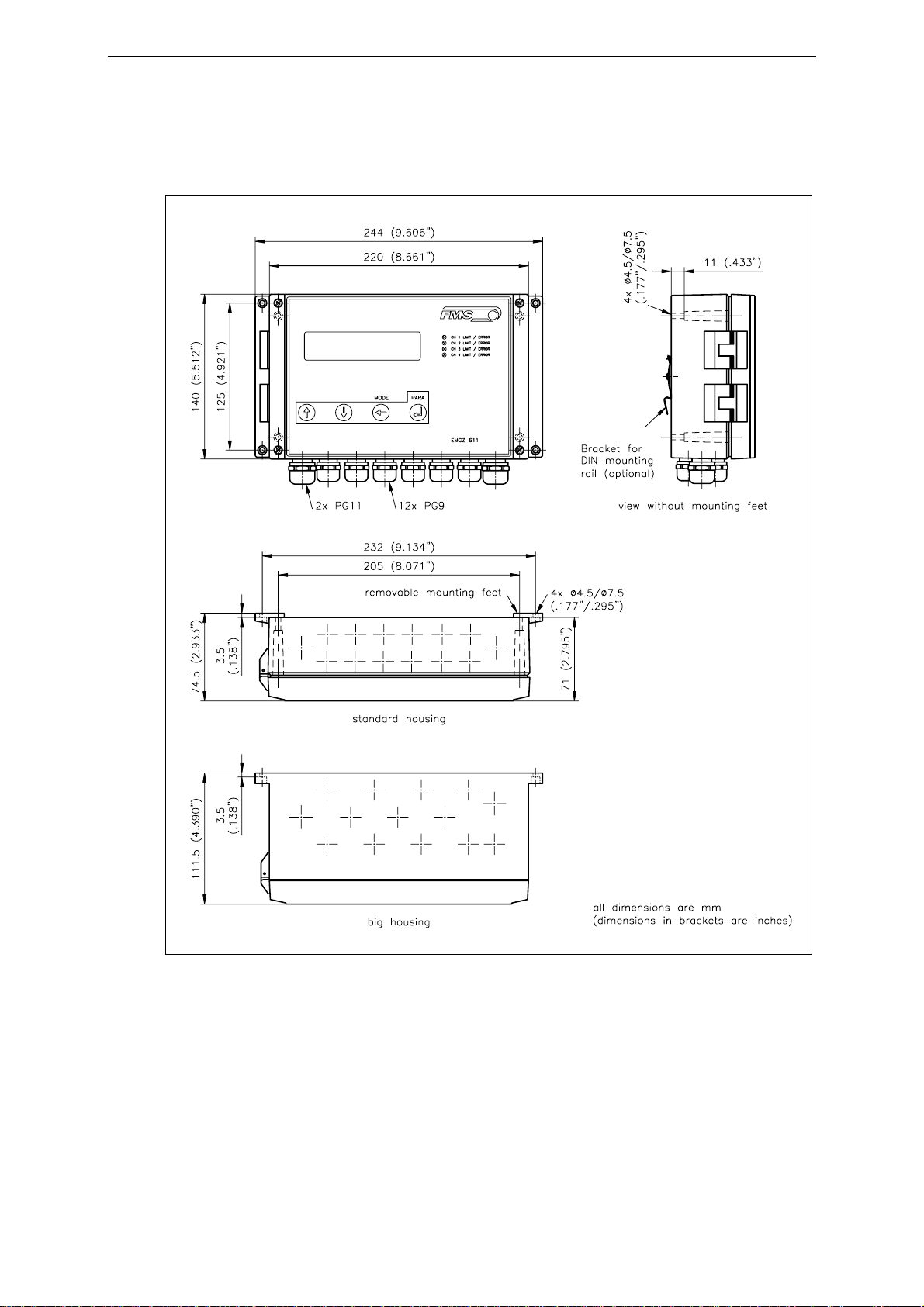

6Dimensions.................................................................................................8

7Installation and Wiring ............................................................................9

7.1 Mounting the Electronic Unit 9

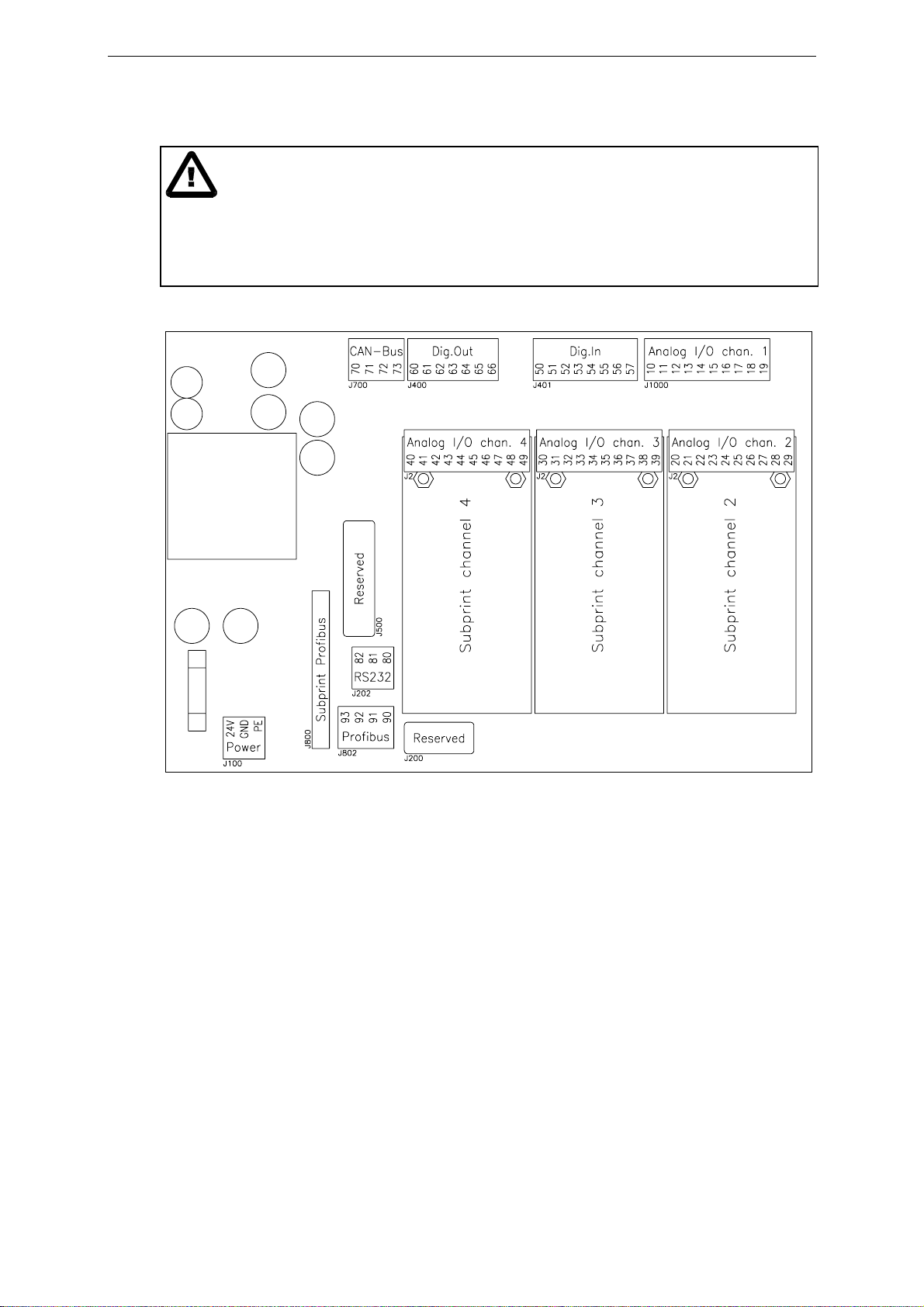

7.2 Wiring Diagram 11

7.3 Mounting the Force Sensors 12

8Operating .................................................................................................13

8.1 View of the Operating Panel 13

8.2 Configuring the Electronic Unit 14

8.3 Calibrating the Measuring Amplifier 15

8.4 Additional Settings 17

9Parametrization.......................................................................................18

9.1 Schematic Diagram of Parametrization 18

9.2 List of the system parameters 19

9.3 List of the parameters EMGZ621A 19

9.4 Description of the system parameters 20

9.5 Description of the Parameters EMGZ621A 21

9.6 Service Mode 25

10 Serial Interface (RS232) .........................................................................26

11 PROFIBUS Interface Description.........................................................27

11.1 Wiring of the PROFIBUS Data Cable 27

11.2 Setting the PROFIBUS Address 28

12 PROFIBUS Interface Description.........................................................29

12.1 GSD File 29

12.2 EMGZ621A DP Slave Functional Description 29

12.3 Initial Parameters 29

12.4 Configuration 30

12.5 Function Code 30

13 Interface CAN-Bus..................................................................................31

14 Interface DeviceNet.................................................................................31

15 Technical Reference................................................................................32

15.1 Additional Setting Elements 32

15.2 Dip-switch for the Analogue Inputs / Outputs 33

15.3 Technical Data 37

16 Trouble Shooting.....................................................................................38