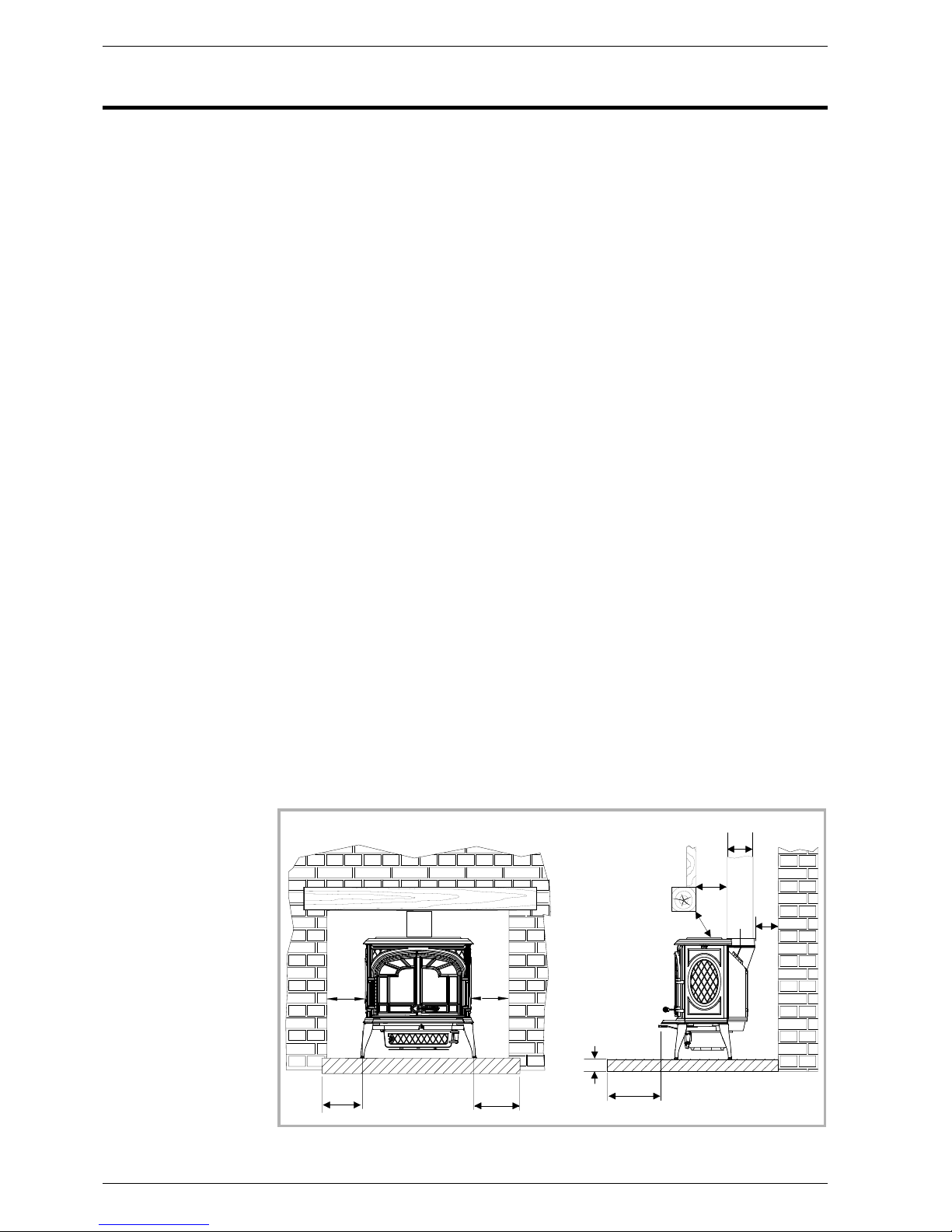

-The flue must be well insulated. If the flue inner wall

surfaces are cold, a good thermal draw is impossible

causing condensation problems (tar formation etc) to

occur.

-The flue must be watertight.

-The flue must not be shared with other appliances.

-The chimney must have a constant cross section.

-When the cross-section of the chimney is too large, it

has difficulties in obtaining a good draught.

-The chimney must be at least 4.5 m (15 ft) high and be

at 40 cm above the ridge of the roof and 8 meters away

from any construction.

-In case of a flat roof or when the roof gradient is lower

than 15°, the stack must be 1,2 m (4 feet) high at least.

-The capping must not restrain the draught.

-If the chimney has any down draught tendency, due to

its position in relation to nearby obstacles, then an

anti-down draught cowl must be installed on the

chimney or the chimney height must be increased.

-If the chimney draught is excessive or irregular, a

draught stabilizer (barometric damper) must be

installed to the connector pipe it must be visible and

accessible.

Flue non-existent :

-The appliance must not support the weight of the flue.

-It must be distant from any combustible material

(walls, cross members)

-It must permit an easy sweeping.

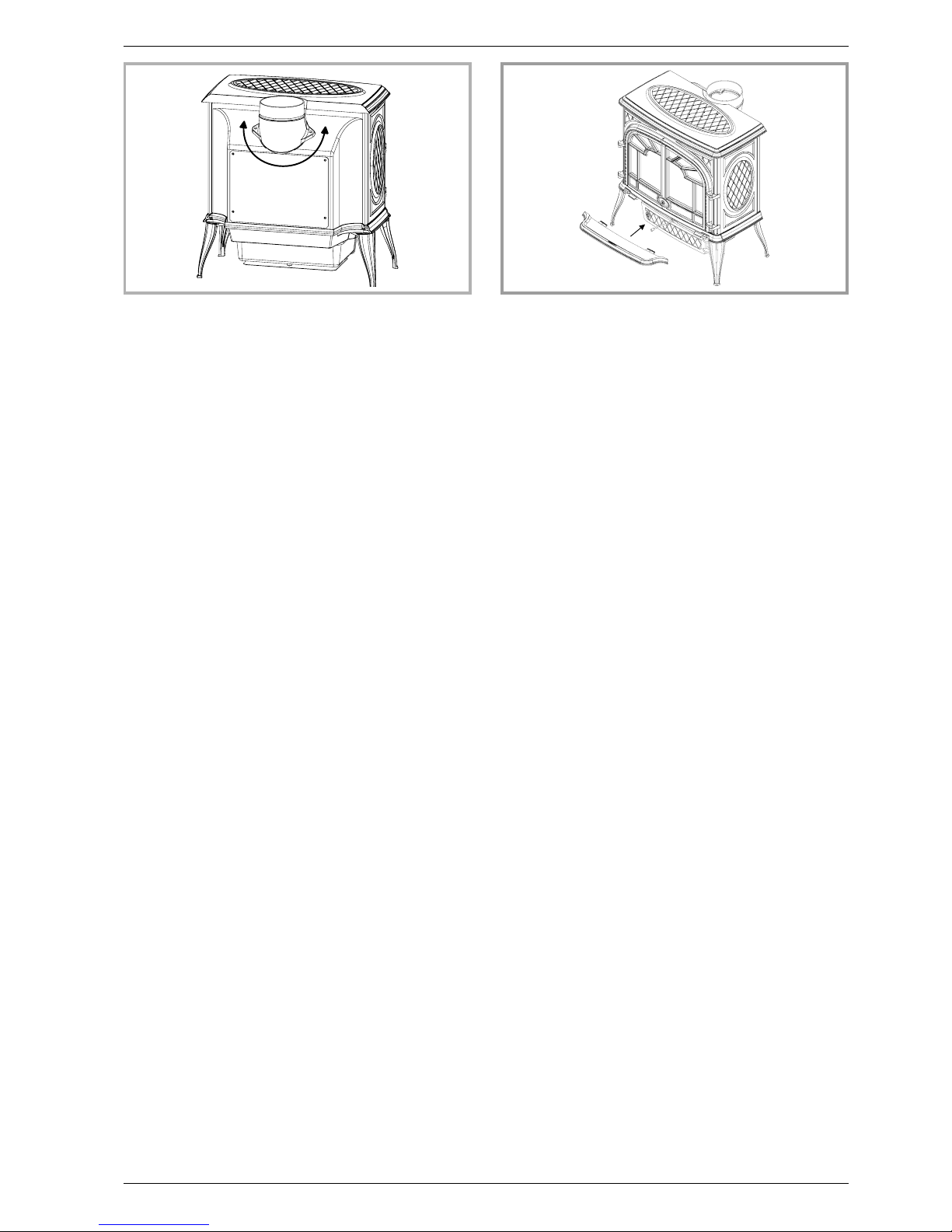

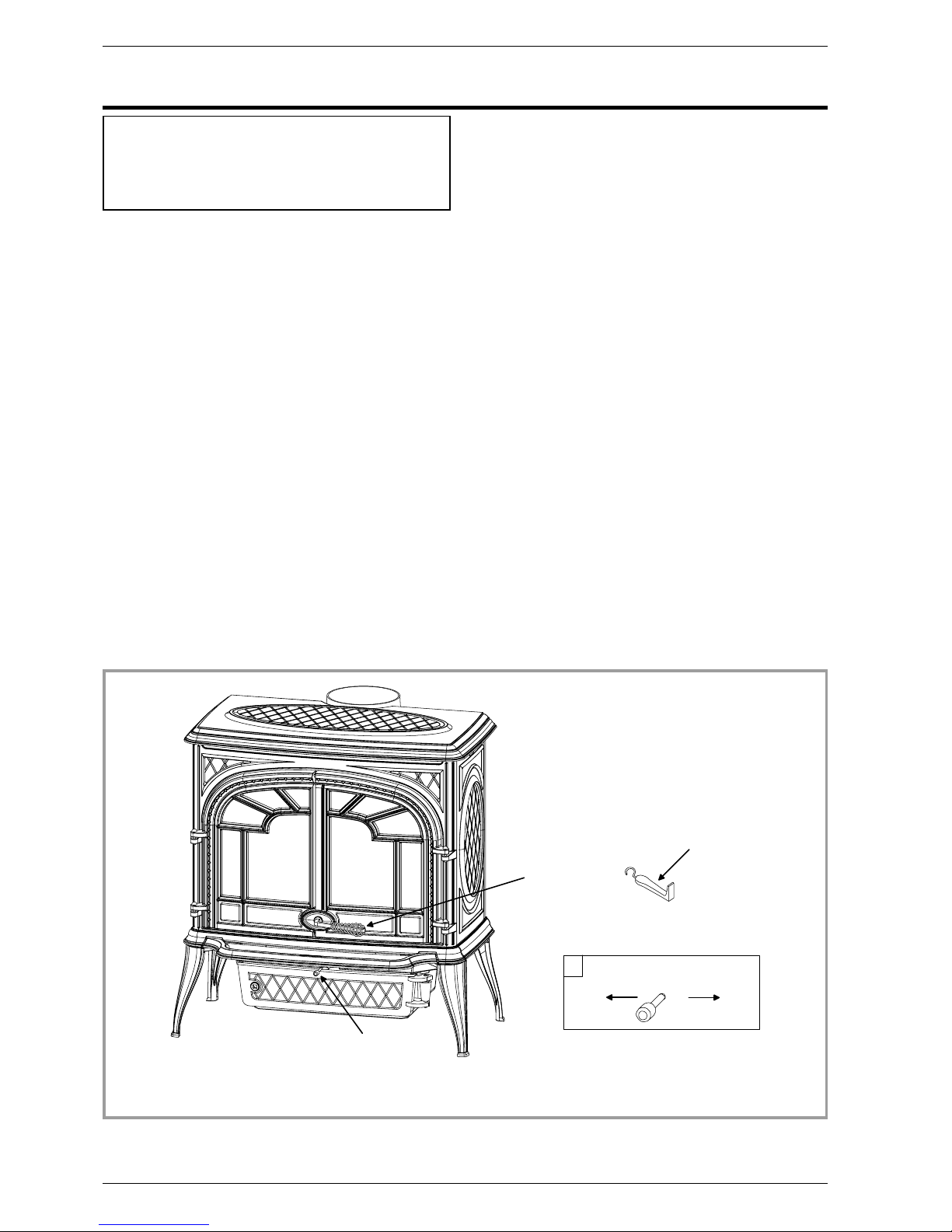

2.4 Mounting the flue collar

The stove is supplied with a connection flue spigot with

an inner diameter of 125 mm and an outer diameter of

139 mm.

Figure 3

The same smoke outlet can be used to install a top or

rear flue. All you have to do is remove the 2 screws and

turn the adapter 180 degrees.

Ensure that the seal is fitted correctly.

2.5 Chimney connector

-The connection to flue must be carried out according

to local building regulations.

-The appliance must be installed as close as possible

to the chimney.

-The connector pipe must be approved for installation

with combustion products (either 24 ga. Black painted

or blued steel or 316 grade 20 ga. Stainless steel or

1 mm vitreous enamelled steel).

-Pipe diameter must not be less than the appliance

spigot diameter. If there is no other solution, the

reduction can not be more than one diameter lower

than the flue spigot and be situated as distant as

possible from the flue connection of the appliance.

-The connection can be either vertical or horizontal. For

horizontal connections, avoid right angle bends.

-The join between the connection pipe and the

stovepipe, and the flue, must be leak tight.

-For the premises equipped with a mechanical

controlled ventilation, the airtightness has to prevent

the exhauster drawing out the smokes from the

exhaust gas pipe.

The connection pipe and any draught stabiliser must

have access for cleaning.

2.6 Mounting the tray

Figure 4

To avoid damage during transport, the tray has been

stored behind the main door.

Centre the tray on tab “A” and lower into place.

2.7 Pre-utilisation check

-Check that the seals of the smoke-line are in good

condition. Check that the door closes correctly. Check

that the glass is not damaged. Check that the smoke

passages are not obstructed by packaging or

removable parts. Check that all removable parts are

correctly installed.

Note : if it acts of a ceramics braid, it is consumable and

thus brought to be changed by the user.

2.8 Maintenance of the Chimney

Very important ! In order to avoid any incident

(chimney fire, etc...), maintenance tasks must be

carried out regularly.

If the appliance is regularly used, the chimney should

be swept several times per year, together with the

stovepipe connection section.

Chimney condition should be checked at least once

per year by a professional engineer.

Technical manual “1146” 5

“ARDENNES” - model 134 13 15 Installation instructions

1 8 0 °

Figure 3 - Mounting the flue collar

)

Figure 4 - Mounting the tray