7

ESC Operation

Thanks for purchasing our electronic speed controller(ESC). The power system for RC model

can be very dangerous, please read this manual carefully. In that we have no control over

the correct use, installation, application, or maintenance of our products, no liability shall be

assumed nor accepted for any damages, losses or costs resulting from the use of the product.

FEATURES:

• Water-proof and dust-proof for all weather races.

• Small size with built-in capacitor module.

• Automatic throttle range calibration, easy to use.

• Multiple protections: Low voltage cut-off protection for Lipo or NiMH battery /

Over-heat protection / Throttle signal loss protection.

• Easily programmed with the jumpers.

SPECIFICATION

* There are 2 kinds of WP-1040-BRUSHED-Crawler& Boat speed controllers, one has 1 output

for 1 motor, and the other one has 2 outputs for 2 motors (2 motors work synchronously).

** The WP-860-DUAL BRUSHED has 2 outputs to drive 2 motors synchronously. When driving 2

motors, the Turns of the motors need to be increased.

BEGIN TO USE

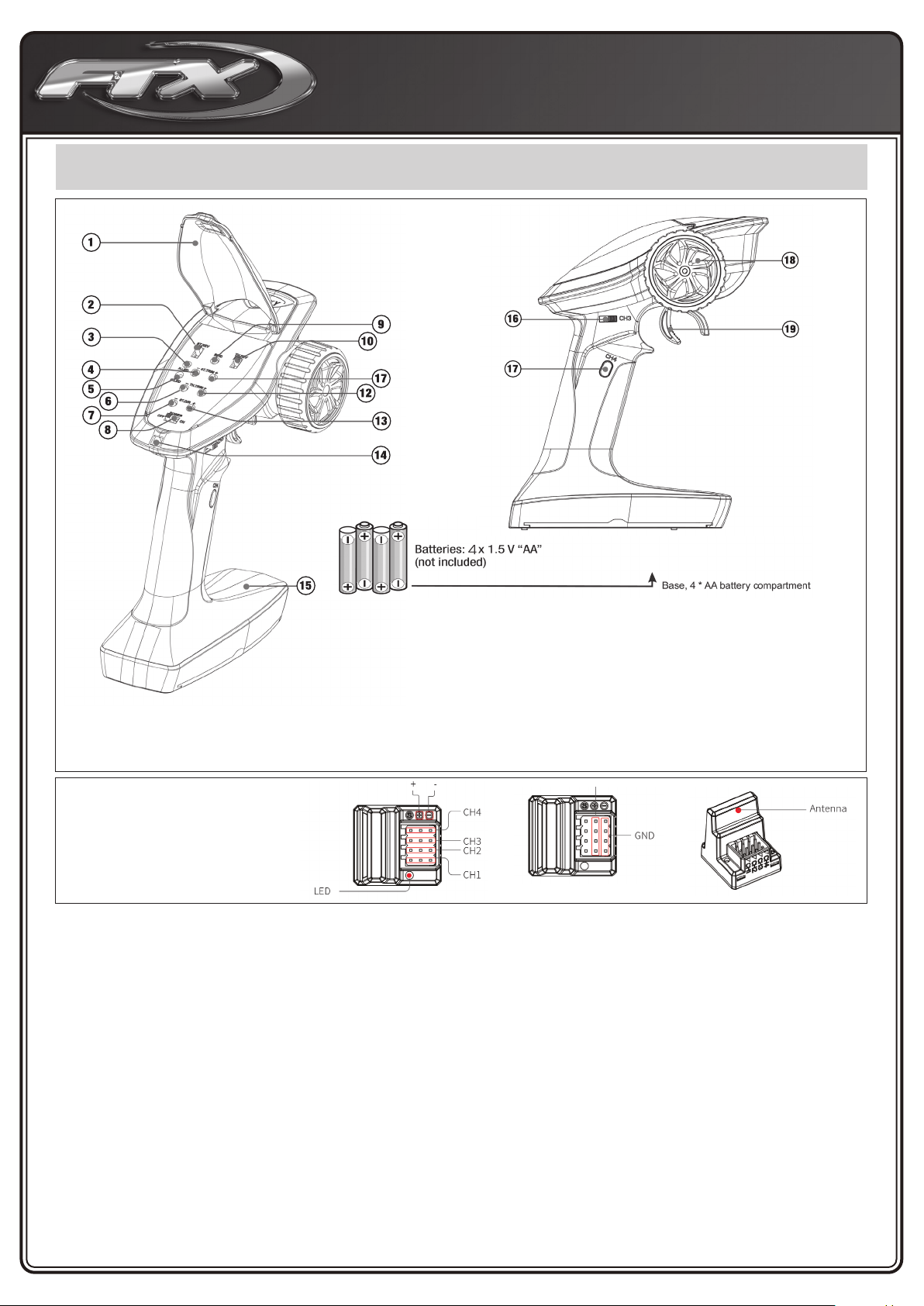

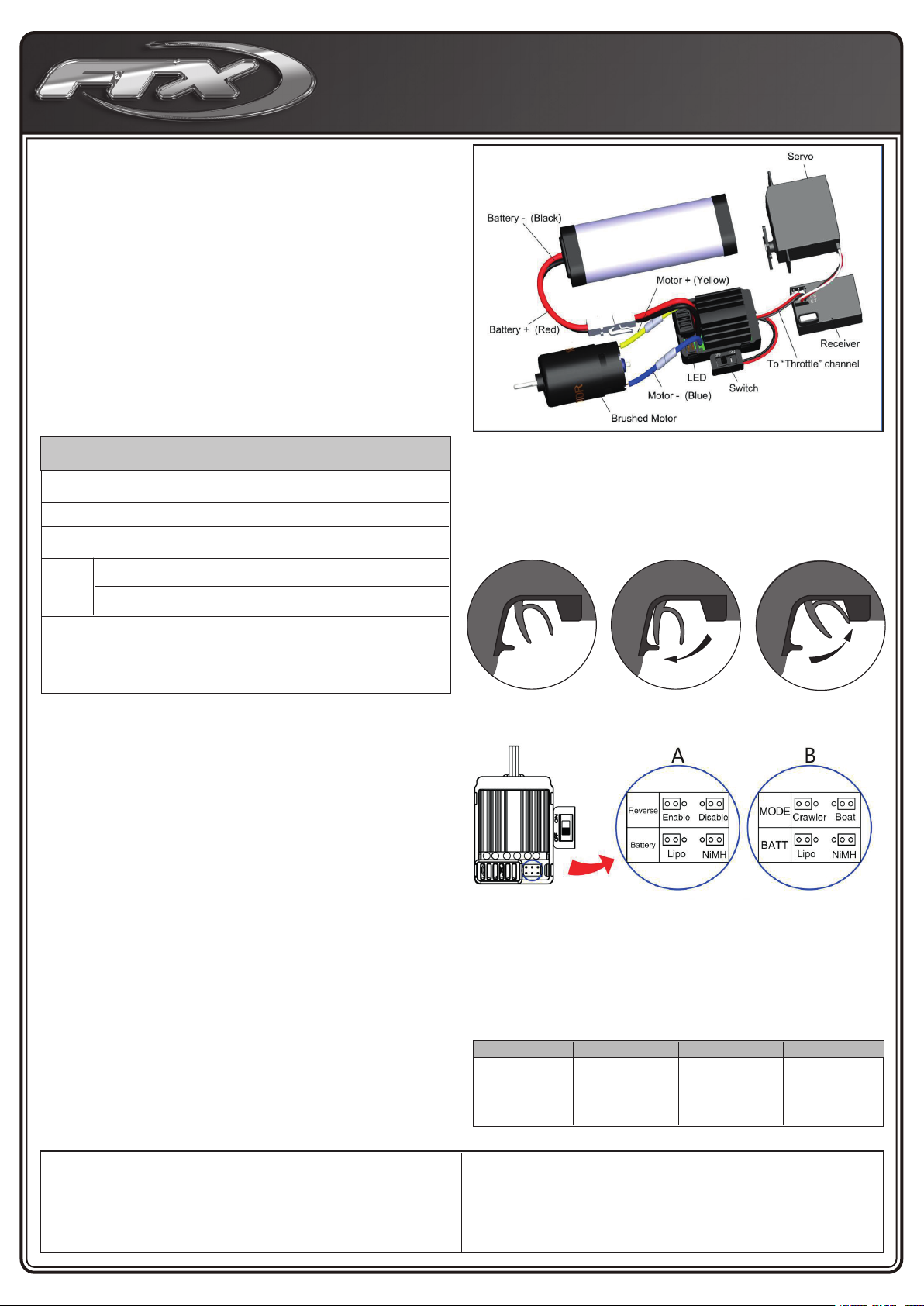

1. Connect the ESC, motor, receiver, battery and servo according to the following diagram:

“+” and “-” wires of the ESC are connected to the battery pack.

Attention: The incorrect polarity will damage the ESC immediately.

The control cable of the ESC (trio wires with black, red and white color) is connected to

the throttle channel of the receiver (Usually CH2). The “Motor +” and “Motor –” wires are

connected to ESC without any order.

If the motor runs in the opposite direction, please swap these two wire connections.

2. Set the Transmitter

Please set the “D/R”, “EPA” and “ATL” to 100% for throttle channel (for transmitter without

LCD, please turn the knobs to the maximum value), and set the “TRIM” of the throttle channel

to 0 (for transmitter without LCD, please turn the TRIM knob to its neutral position).

For FutabaTM and the similar transmitters, the direction of throttle

channel shall be set to “REV”, while other radio systems shall be set to “NOR”.

The “Fail Save” function of the radio system is strongly recommended to be activated. Please

make sure that the motor can be stopped when the “Fail Save” happens.

3. Throttle Range Setting (Throttle Range Calibration)

In order to make the ESC match the throttle range of different transmitters, the calibration of

the ESC is necessary.

To calibrate the ESC, please turn on the transmitter, keep throttle stick at its neutral position,

wait for 3 seconds to let the ESC execute self-test and automatic throttle calibration. When the

ESC is ready to run, a long beep sound is emitted from the motor.

Note: Please calibrate the throttle range again when using a new transmitter or changing the

settings of the neutral position of throttle channel, D/R, ATV, ATL or EPA parameters,otherwise

the ESC may not work properly.

BEEP SOUND AND LED STATUS

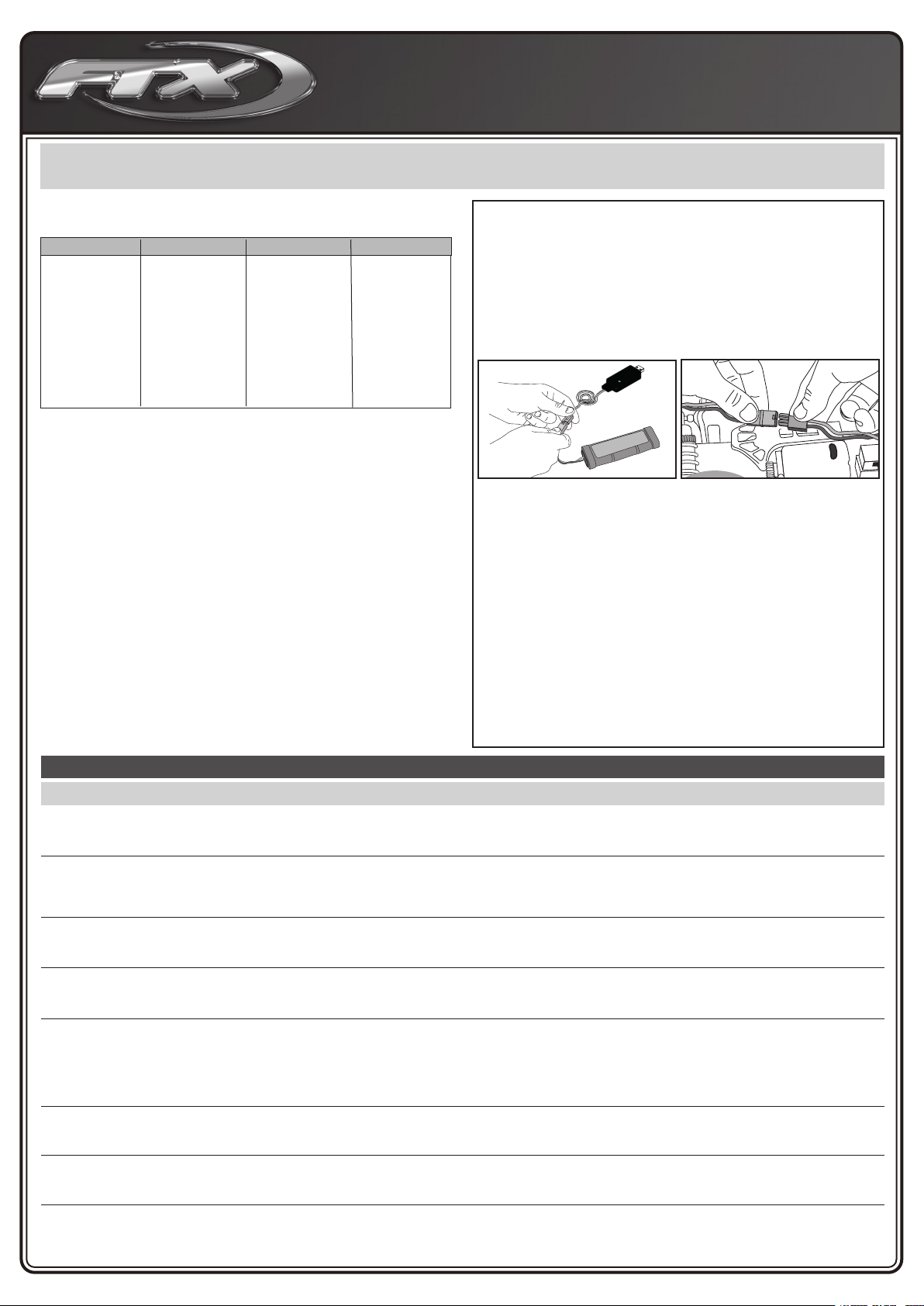

SET THE ESC

The ESC is programmed by the jumpers

(Tweezers are recommended to plug and unplug the jumper).

PROTECTION FUNCTIONS

1. Low voltage Cut-off (LVC) protection: If the voltage of battery pack is lower than the

threshold for 2 seconds, the ESC will enter the protection mode.

When the car stops, the red LED blinks to indicate the low voltage cut-off protection has been

activated.

Table A: LVC protection for WP-1060-BRUSHED, WP-1040-

BRUSHED, WP-860-DUAL BRUSHED (F/B/R or F/B mode).

Model WP-1040-BRUSHED

WP-1040-BRUSHED-Crawler & Boat *

Cont. / Burst Current Forward: 40A / 180A

Backward: 20A / 90A

Input 2-3S Lipo, 5-9 Cells NiMH

Cars Applicable 1:10 on-road, off-road Buggy, Truggy, SCT

1:10 Crawler, Tank & Boat

Motor

Limit

2S Lipo or

5-6 cells NiMH

3S Lipo or

7-9 cells NiMH

540 or 550 size motor ≥12T

or RPM < 30000 @7.2V

540 or 550 size motor ≥18T

or RPM < 20000 @7.2V

Resistance Fwd: 0.002 Ohm, Bwd: 0.004 Ohm

Built-in BEC 2A/6V (Linear mode BEC)

Dimension &

Weight WP-1040-BRUSHED: 46.5*34*28.5, 65g

WP-1040-BRUSHED-CRAWLER: 46.5*34*28.5, 70g

Neutral Point Top point of forward

direction Top point of backward

direction

THROTTLE STICK POSITION

User Manual of Water-Proof Brushed Speed Controller (RTR Version) HW-SM690ENG-V3-20160603Page - 1 -

Thanks for purchasing our electronic speed controller(ESC). The power system for RC model can be very

dangerous, please read this manual carefully. In that we have no control over the correct use, installation,

application, or maintenance of our products, no liability shall be assumed nor accepted for any damages,

losses or costs resulting from the use of the product.

【【FEATURES】】

1. Water-proof and dust-prooffor all weather races.

2. Small size with built-in capacitor module.

3. Automatic throttle range calibration, easy to use.

4. Multiple protections: Low voltage cut-off protection for Lipo or NiMH battery / Over-heat protection / Throttle signal

5. Easily programmed with the jumpers.

【【SPECIFICATIONS】】

* There are 2 kinds of WP-1040-BRUSHED-Crawler& Boat speed controllers, one has 1 output for 1 motor, and the other

one has 2 outputs for 2 motors (2 motors work synchronously).

** The WP-860-DUAL BRUSHED has 2 outputs to drive 2 motors synchronously. When driving 2 motors, the Turns of the

motors need to be increased.

【【BEGIN TO USE】】

1. Connect the ESC, motor, receiver, battery and servo according to the following diagram

“+” and “-” wires of the ESC are connected to the battery pack.

Attention: The incorrect polarity will damage the ESC immediately.

The control cable of the ESC (trio

wires with black, red and white color)

is connected to the throttle channel

of the receiver (Usually CH2). The

“Motor +” and “Motor –” wires are

connected to ESC without any order.

If the motor runs in the opposite

direction, please swap these two

Please set the “D/R”, “EPA” and

“ATL” to 100% for throttle channel

(for transmitter without LCD, please

turn the knobs to the maximum

value), and set the “TRIM” of the

throttle channel to 0 (for transmitter

without LCD, please turn the TRIM

knob to its neutral position).

For FutabaTM and the similar

transmitters, the direction of throttle

channel shall be set to “REV”, while

other radio systems shall be set to “NOR”.

The “Fail Save” function of the radio system is strongly recommended to be activated. Please make sure that the motor

can be stopped when the “Fail Save” happens.

3. Throttle Range Setting (Throttle Range Calibration)

In order to make the ESC match the throttle range of different transmitters, the calibrationof the ESC is necessary.

To calibrate the ESC, please turn on the transmitter, keep throttle stick at its neutral position, wait for 3 seconds to let the

ESC execute self-test and automatic throttle calibration. When the ESC is ready to run, a long beep sound is emitted

from the motor.

Note: Please calibrate the throttle range again when using a new transmitter or changing the settings of the neutral

position of throttle channel, D/R, ATV, ATL or EPA parameters,otherwise the ESC may not work properly.

【【BEEP SOUND AND LED STATUS】】

The Meaning of Beep Sound

1 short Beep: The battery is NiMH/NiCd

2 short Beeps: The battery is 2S Lipo

3 short Beeps: The battery is 3S Lipo

4 short Beeps: The battery is 4S Lipo

1 long Beep: Self-test and throttle calibration is

OK, the ESC is ready to run

When the throttle stick is in neutral range, red LED is off

Forward, brake or reverse at partial throttle, red LED blinks

Forward, brake or reverse at full throttle, red LED is solid

【【THROTTLE STICK POSITION】】

【【SET THE ESC】】

The ESC is programmed by the jumpers

(Tweezers is recommended to plug and unplug the jumper).

WP-1040-BRUSHED

WP-1040-BRUSHED-Crawler& Boat *

Forward: 40A / 180A

Backward: 20A / 90A

Forward: 60A / 360A

Backward: 30A / 180A

2-3S Lipo, 5-9 Cells NiMH

1:10 on-road, off-road Buggy, Truggy, SCT

1:10 Crawler, Tank &Boat

540 or 550 size motor ≥12T

or RPM < 30000 @7.2V

540 or 550 size motor ≥ 8T

or RPM <45000 @7.2V

540 or 550 size motor ≥18T

or RPM < 20000 @7.2V

540 or 550 size motor ≥13T

or RPM <30000 @7.2V

Fwd: 0.002 Ohm, Bwd: 0.004 Ohm

Fwd: 0.0008 Ohm, Bwd: 0.0016 Ohm

WP-1040-BRUSHED: 46.5*34*28.5, 65g

WP-1040-BRUSHED-CRAWLER: 46.5*34*28.5, 70g

WP-1625-BRUSHED

WP-1625-BRUSHED-Crawler

Forward: 25A / 100A

Backward: 25A / 100A

Forward: 60A / 360A

Backward: 30A / 180A

2-3S Lipo, 5-9 Cells NiMH

2-4S Lipo, 10-12 Cells NiMH

1:18 & 1:16 on-road, off-road

1:18 & 1:16 Crawler and Boat

1:8 on-road, off-road, Buggy, Truggy, Monster

Crawler and Boat

280, 370 or 380 size motor

or RPM < 30000 @7.2V

540, 550 or 775 size motor ≥12T

or RPM < 30000 @7.2V

280, 370 or 380 size motor

or RPM <20000 @7.2V

540, 550 or 775 size motor ≥18T

or RPM <20000 @7.2V

540, 550 or 775 size motor ≥24T

or RPM <15000 @7.2V

Fwd: 0.003 Ohm, Bwd: 0.003 Ohm

Fwd: 0.001 Ohm, Bwd: 0.002 Ohm

SPEED CONTROL CONNECTION DIAGRAM

The Meaning of Beep Sound

• 1 short Beep: The battery is NiMH/NiCd

• 2 short Beeps: The battery is 2S Lipo

• 3 short Beeps: The battery is 3S Lipo

• 4 short Beeps: The battery is 4S Lipo

• 1 long Beep: Self-test and throttle calibration is OK, the ESC is ready to run

LED Status

• When the throttle stick is in neutral range, red LED is off

• Forward, brake or reverse at partial throttle, red LED blinks

• Forward, brake or reverse at full throttle, red LED is solid

User Manual of Water-Proof Brushed Speed Controller (RTR Version) HW-SM690ENG-V3-20160603Page - 2 -

【PROTECTION FUNCTIONS】

1. Low voltage Cut-off (LVC) protection: If the voltage of battery pack is lower than the threshold for 2 seconds, the

ESC will enter the protection mode.

When the car stops, the red LED blinks to indicate the low voltage cut-off protection has been activated.

Table A: LVC protection for WP-1060-BRUSHED, WP-1040-BRUSHED, WP-860-DUAL BRUSHED (F/B/R or F/B

mode).

Output reduces 50% at 6.5V

Output cuts off at 6.0V,

cannot be recovered

Output reduces 50% at 9.75V

Output cuts off at 9.0V, cannot

be recovered

Output reduces 50% at 13V

Output cuts off at 12V, cannot

be recovered

Output reduces 50% at 4.5V

Output cuts off at 4.0V, cannot

be recovered

Table B: LVC protection for WP-1625-BRUSHED-Crawler, WP-1040-BRUSHED-Crawler&Boat, WP-860-DUAL

BRUSHED (Crawler or Boat mode).

Output cuts off at 6.5V.

If the throttle stick moves to

neutral and then up again, the

output can be recovered to

50%.

If the voltage drops to 6.5V

again, the above process

repeats in circles.

Output cuts off at 9.75V.

If the throttle stick moves to

neutral and then up again, the

output can be recovered to

50%.

If the voltage drops to 9.75V

again, the above process

repeats in circles.

Output cuts off at 13V.

If the throttle stick moves to

neutral and then up again, the

output can be recovered to

50%.

If the voltage drops to 13V

again, the above process

repeats in circles

Output cuts off at 4.5V.

If the throttle stick moves to

neutral and then up again, the

output can be recovered to

50%.

If the voltage drops to 4.5V

again, the above process

repeats in circles.

2. Over-heat protection: When the internal temperature of the ESC is higher than 100 Celsius degree or 212

Fahrenheit degree for 5 seconds, the ESC will reduce and cut off the output power.

When the car stops, the red LED blinks to indicate the over-heat protection has been activated. If the ESC cools

down to 80 Celsius degree (176 Fahrenheit degree) the output power is recovered to normal state.

3. Throttle signal loss protection: The ESC will cut off the output power if the throttle signal has been lost for 0.1 second.

The “Fail Save” function of the radio system is strongly recommended to be activated.

【THE DIFFERENCE BETWEEN “BRUSHED” AND “BRUSHED-CRAWLER& BOAT” ESC】

1. “Brushed” and “Brushed-Crawler& Boat” ESCs have different backward-running modes.

“Brushed” ESC uses “Double-Click” method to make the car go backward. When you move the throttle stick from

forward zone to backward zone for the first time, the ESC begins to brake the motor, the motor speeds down but

still running, so the backward action is NOT happened at this moment. When the throttle stick is moved to the

backward zone again (The 2nd “click”), if the motor speed is slowed down to zero (i.e. stopped), the backward

action will be activated. The “Double-Click” method prevents mistakenly reverse when the brake function is

frequently used in steering.

“Brushed-Crawler& Boat” ESC uses “Single-click” to make the car go backward. When you move the throttle stick

from forward zone to backward zone, the car will go backward immediately. This mode is common for the Rock

Crawler and tank.

2. The maximum reverse force (for backward running) is 50% for the general “Brushed” ESC, 100% for the “Crawler”

mode of a “Brushed-Crawler & Boat” ESC, and 25% for the "Boat" mode of a “Brushed-Crawler & Boat” ESC.

3. The Low Voltage Cut-off Protection modes are different (Please check the instructions in the section of

“PROTECTION FUNCTIONS”).

【TROUBLE SHOOTING】

After power on, motor can’t work, no

sound is emitted, and LED is off.

The ESC doesn’t get its working

voltage; Connections between

battery pack and ESC are

Check the battery wires connection

or replace the defective connectors.

After power on, motor can’t work; red

Throttle signal is abnormal.

Check the throttle wire connection;

make sure it is plugged into the

throttle channel of the receiver.

Set the “TRIM” of throttle channel to

0 or turn the knob to its neutral

The car runs backward while giving

throttle.

(The motor runs in the opposite

The wire connections between

ESC and the motor need to be

changed.

Swap two wire connections between

The car can’t go backward.

The jumper position is wrong.

Check the jumper and plug it to the

correct position.

The neutral point of throttle

channel is changed or drifted.

Set the “TRIM” of throttle channel to

0 or turn the knob to its neutral

The car can’t go forward, but can go

The direction of throttle channel

Reset the direction of throttle

channel from original “NOR” to

“REV”, or from original “REV” to

The motor doesn’t work, but the LED in

The connections between motor

and ESC are broken.

Check the connections and replace

the defective connectors.

The motor suddenly stops running

The throttle signal is lost.

Check the transmitter and the

Check the throttle wire connection.

Low voltage cut-offprotection

or Over-heat cut-off protection

Replace the battery pack, or cool

The car cannot get top speed and the

red LED doesn’t solid on at full throttle

Some setting in the transmitter

Set D/R, EPA, ATL to 100% or turn

the knobs to maximum value.

Set TRIM to 0 or turn the knob to its

Motor is cogging when accelerated

The battery has limited

discharge ability.

Use battery with better discharge

ability.

Motor RPM is too high, the gear

Use motor with lower RPM, or use

smaller pinion to get softer gear

Something wrong in the driving

system of the car.

Check the driving system of the car.

Output reduces 50%

at 6.5V Output cuts

off at 6.0V, cannot be

recovered

Output reduces 50%

at 9.75V Output cuts

off at 9.0V, cannot be

recovered

Output reduces 50%

at 13V Output cuts

off at 12V, cannot be

recovered

Output reduces 50%

at 4.5V Output cuts

off at 4.0V, cannot be

recovered

2S Lipo 3S Lipo 4S Lipo 5-9 cells NiMH