Furuno FSV-25 MARK-2 User manual

Other Furuno Marine Equipment manuals

Furuno

Furuno GP-1650F User manual

Furuno

Furuno GP-1850WDF User manual

Furuno

Furuno FCV-295 User manual

Furuno

Furuno FE-881 II User manual

Furuno

Furuno VR-7000 User manual

Furuno

Furuno LS-6100 User manual

Furuno

Furuno FMD-3200 User manual

Furuno

Furuno SC-33 User manual

Furuno

Furuno FI-304 User manual

Furuno

Furuno DS-50 User manual

Furuno

Furuno DS-50 User manual

Furuno

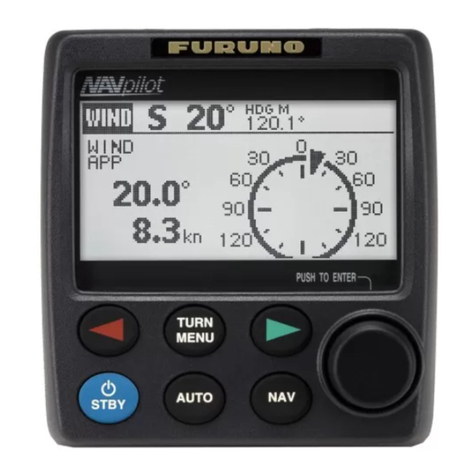

Furuno NavPilot 711 User manual

Furuno

Furuno BBDS1 User manual

Furuno

Furuno FCV-667 User manual

Furuno

Furuno IF-1002 User manual

Furuno

Furuno DFF1 User manual

Furuno

Furuno NavNet TZtouch3 Series User manual

Furuno

Furuno FI-501 User manual

Furuno

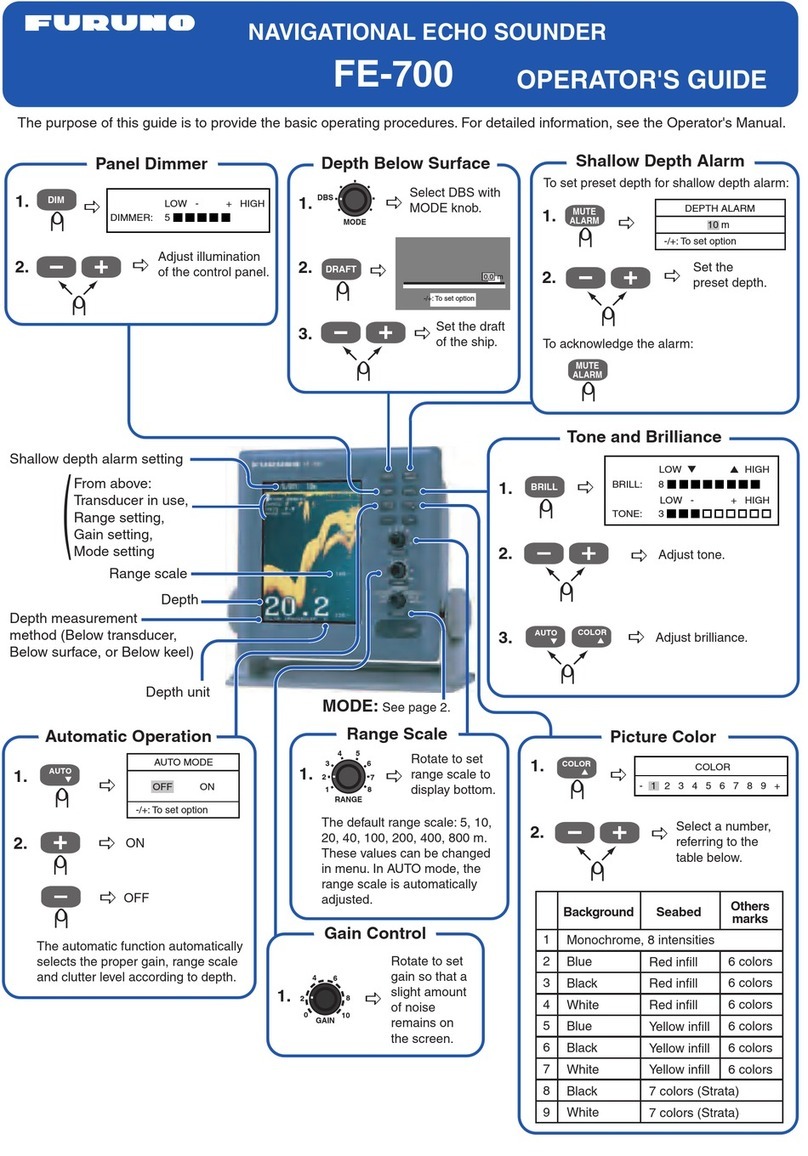

Furuno FE-700 Manual

Furuno

Furuno FCV-1100L User manual

Popular Marine Equipment manuals by other brands

GUIDANCE MARINE

GUIDANCE MARINE 20- Series Installer's guide

Raymarine

Raymarine ST60 Tridata Owner's handbook

Sonic

Sonic 2024 Operation manual

Quicksilver

Quicksilver 88688A25 Installation, operation and maintenance instructions

olympia electronics

olympia electronics ΒS-532/WP quick start guide

olympia electronics

olympia electronics ΒS-531/1/MAR quick start guide