Furuno VR-5020 User manual

Other Furuno Marine Equipment manuals

Furuno

Furuno CSH-5 MARK-2 Manual

Furuno

Furuno Color Video Sounder FCV-522 User manual

Furuno

Furuno FMD3100 Manual

Furuno

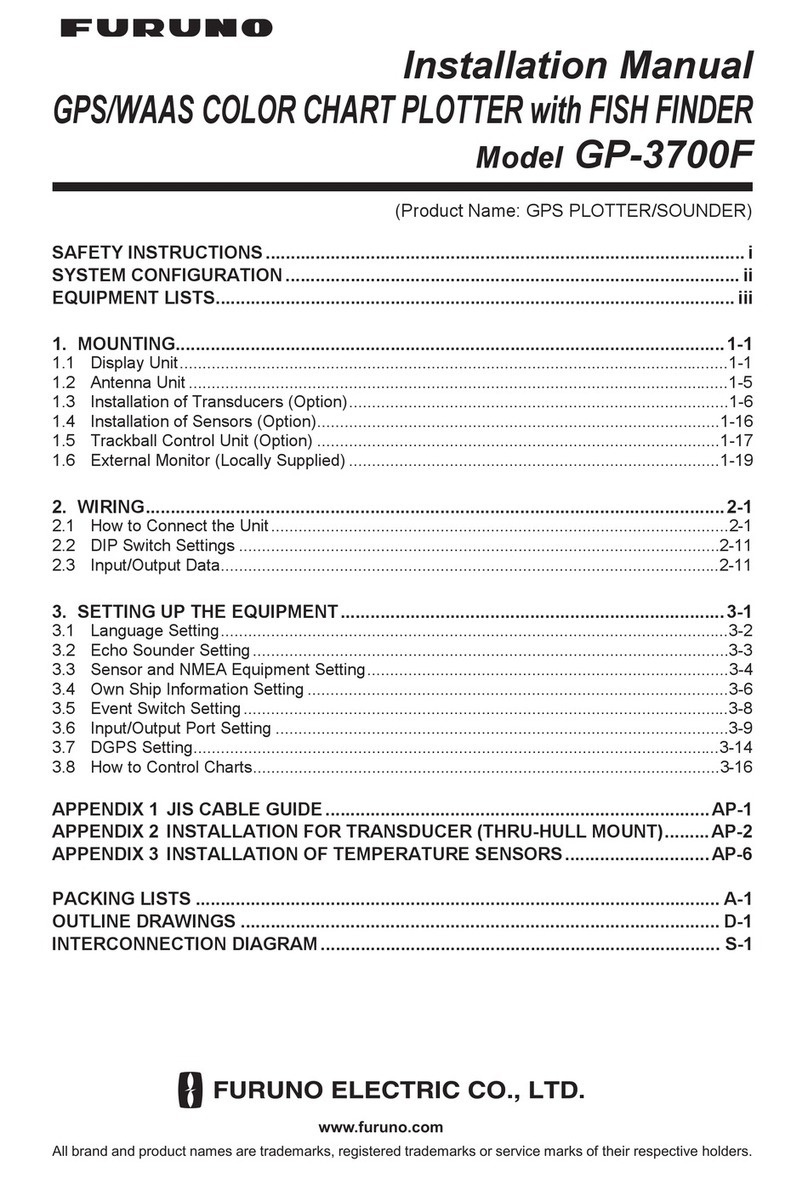

Furuno GP-3700F User manual

Furuno

Furuno SC-33 User manual

Furuno

Furuno FCV-1200L User manual

Furuno

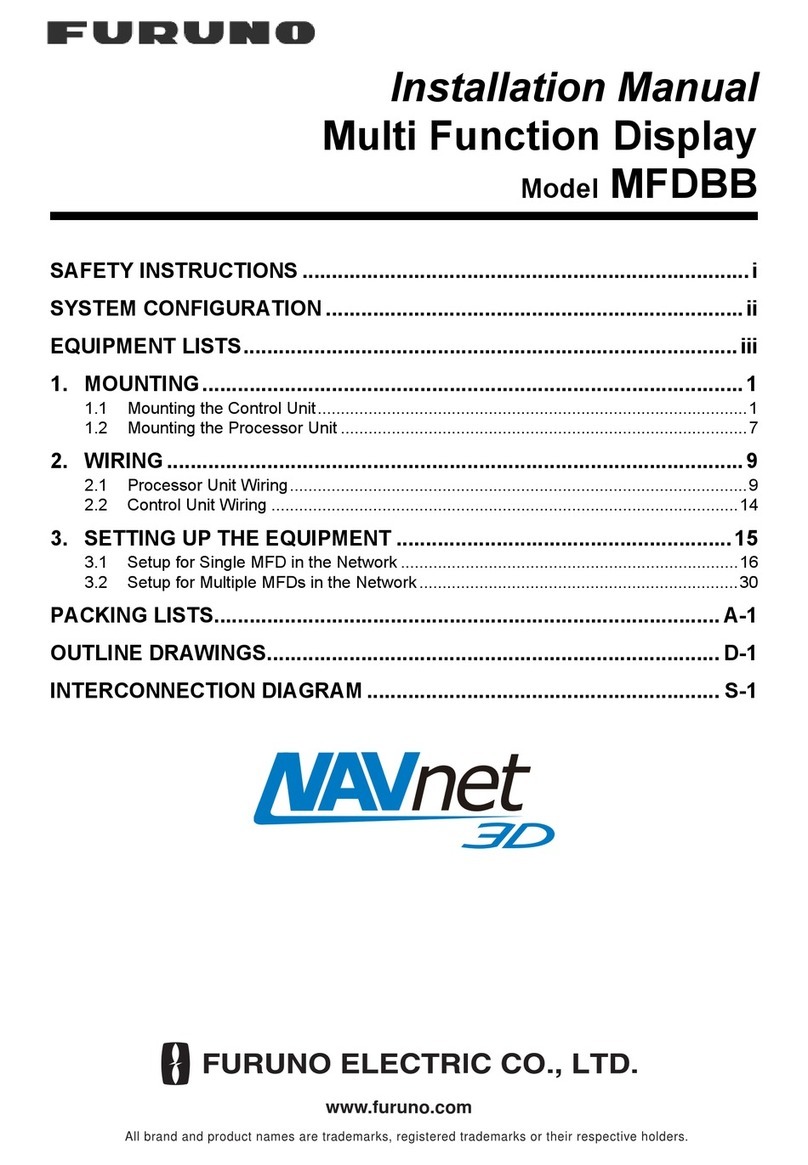

Furuno NAVNET 3D MFDBB Mounting instructions

Furuno

Furuno FELCOM 15 User manual

Furuno

Furuno GP-1650WF Maintenance and service guide

Furuno

Furuno FI-501 User manual

Furuno

Furuno FMD-3200 User manual

Furuno

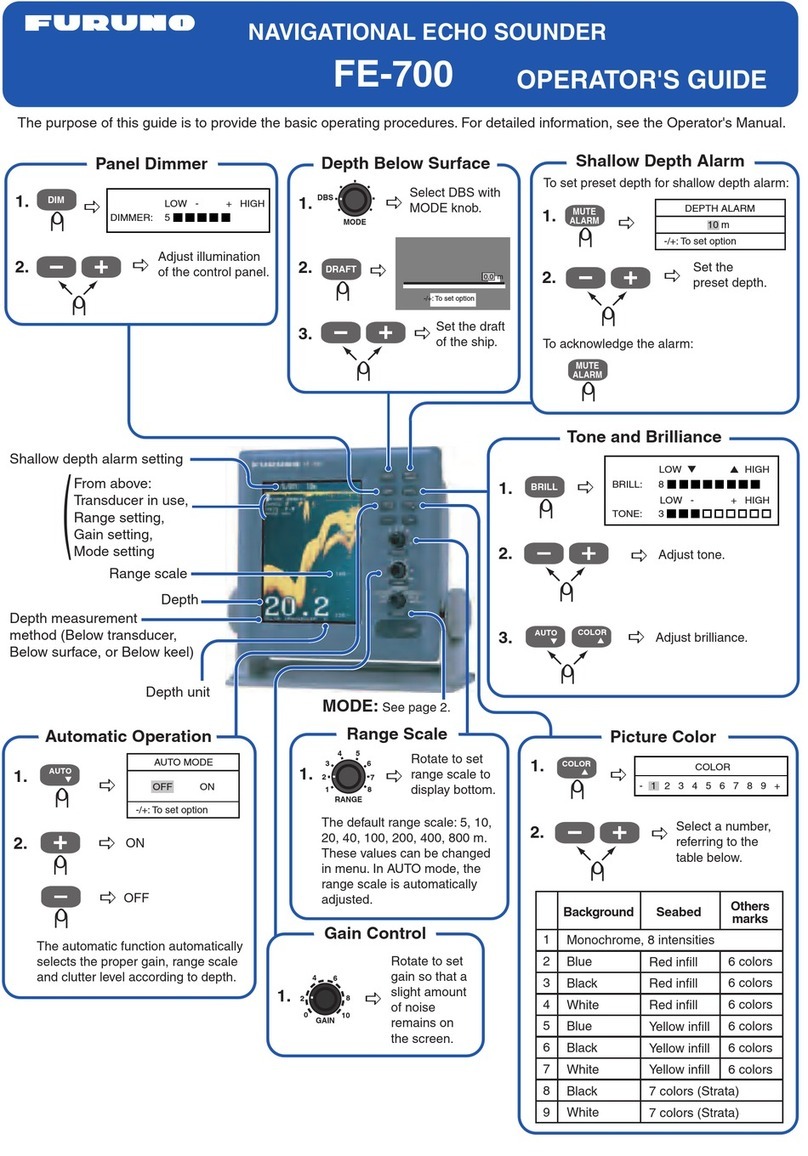

Furuno FE-700 User manual

Furuno

Furuno FE-700 Manual

Furuno

Furuno FELCOM19 Inmarsat Mini-C MES User manual

Furuno

Furuno FE-4300 User manual

Furuno

Furuno MFDBB User manual

Furuno

Furuno LH-5000 User manual

Furuno

Furuno FCV-600L User manual

Furuno

Furuno NAVpilot-300 Installation guide

Furuno

Furuno GP-1650DF User manual

Popular Marine Equipment manuals by other brands

GUIDANCE MARINE

GUIDANCE MARINE 20- Series Installer's guide

Raymarine

Raymarine ST60 Tridata Owner's handbook

Sonic

Sonic 2024 Operation manual

Quicksilver

Quicksilver 88688A25 Installation, operation and maintenance instructions

olympia electronics

olympia electronics ΒS-532/WP quick start guide

olympia electronics

olympia electronics ΒS-531/1/MAR quick start guide