Pub. 42004-308G

GAI-TRONICS 3030 KUTZTOWN RD. READING, PA 19605 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

GAI-TRONICS®

AHUBBELL COMPANY

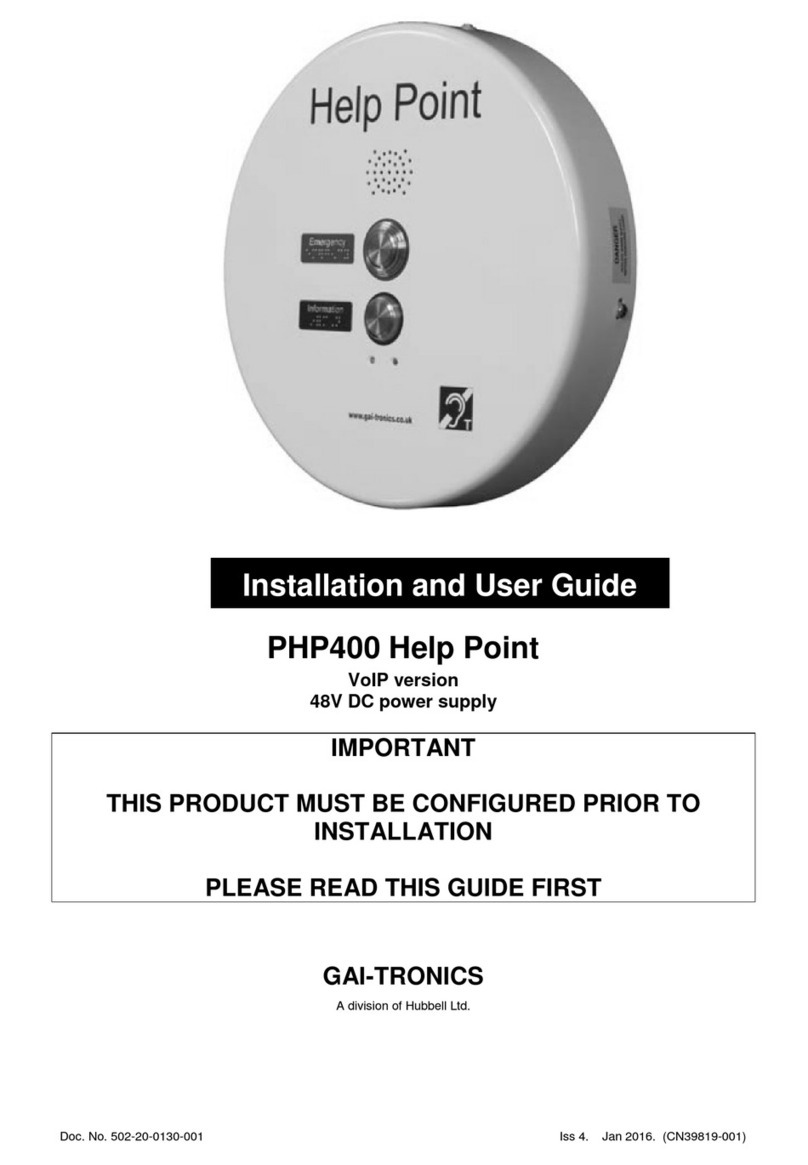

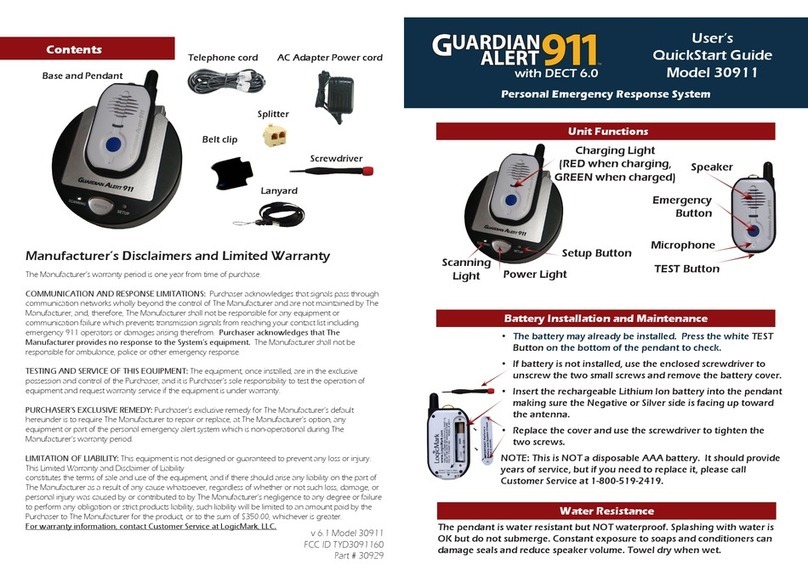

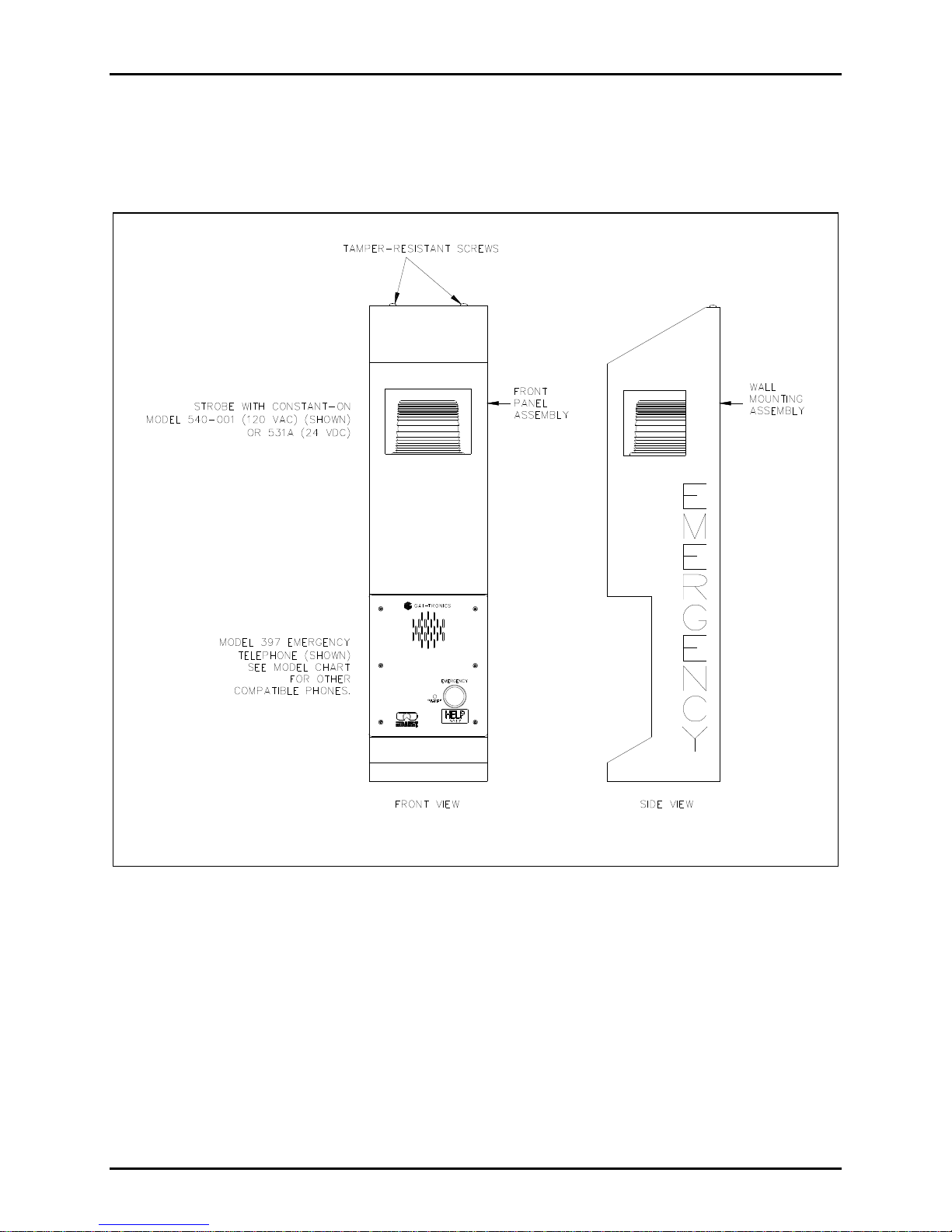

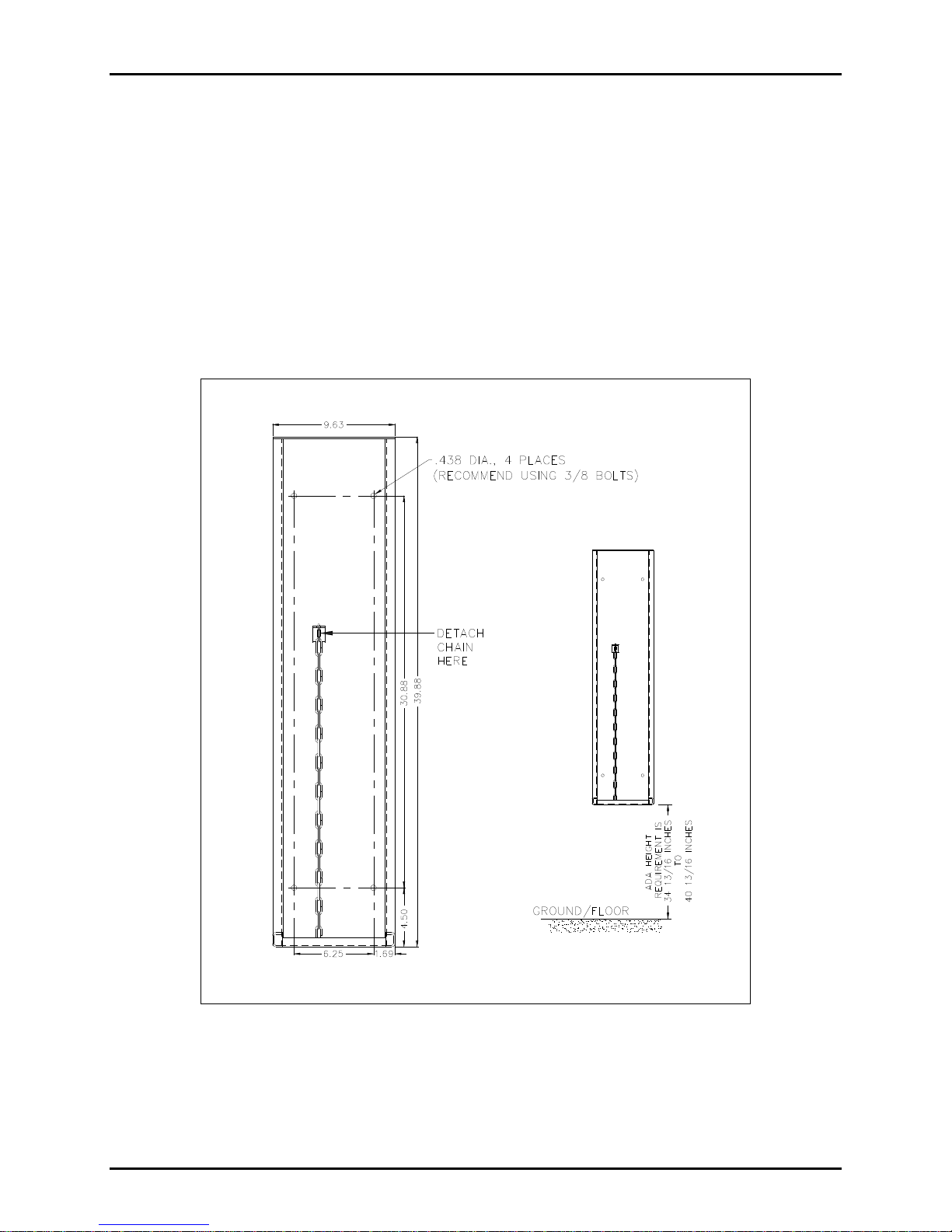

Model 234WM-202

Wall-Mount Stanchion Assembly

Confidentiality Notice

This manual is provided solely as an installation, operation, and maintenance guide, which contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAI-

Tronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form; in whole or in part, directly or indirectly, to any

third party.

General Information

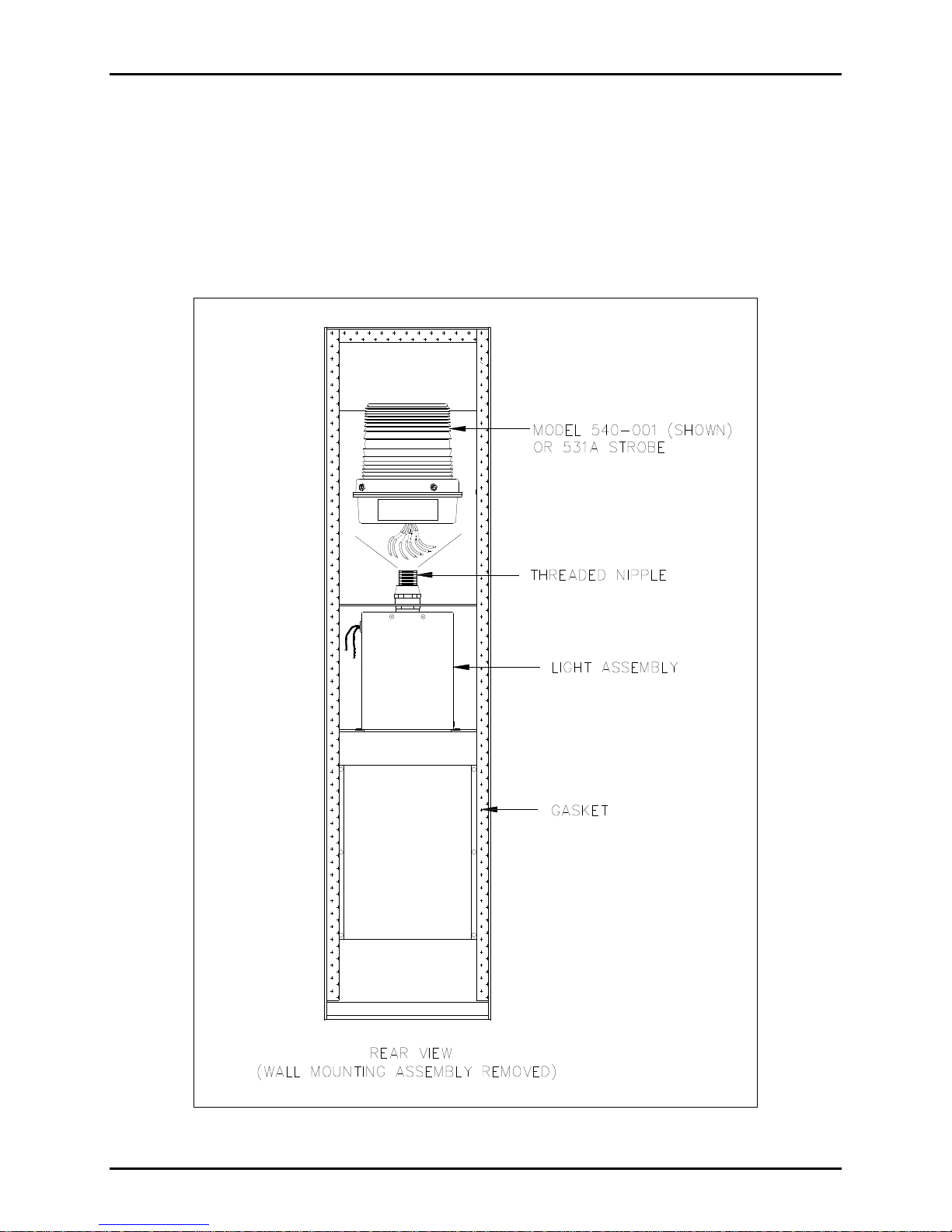

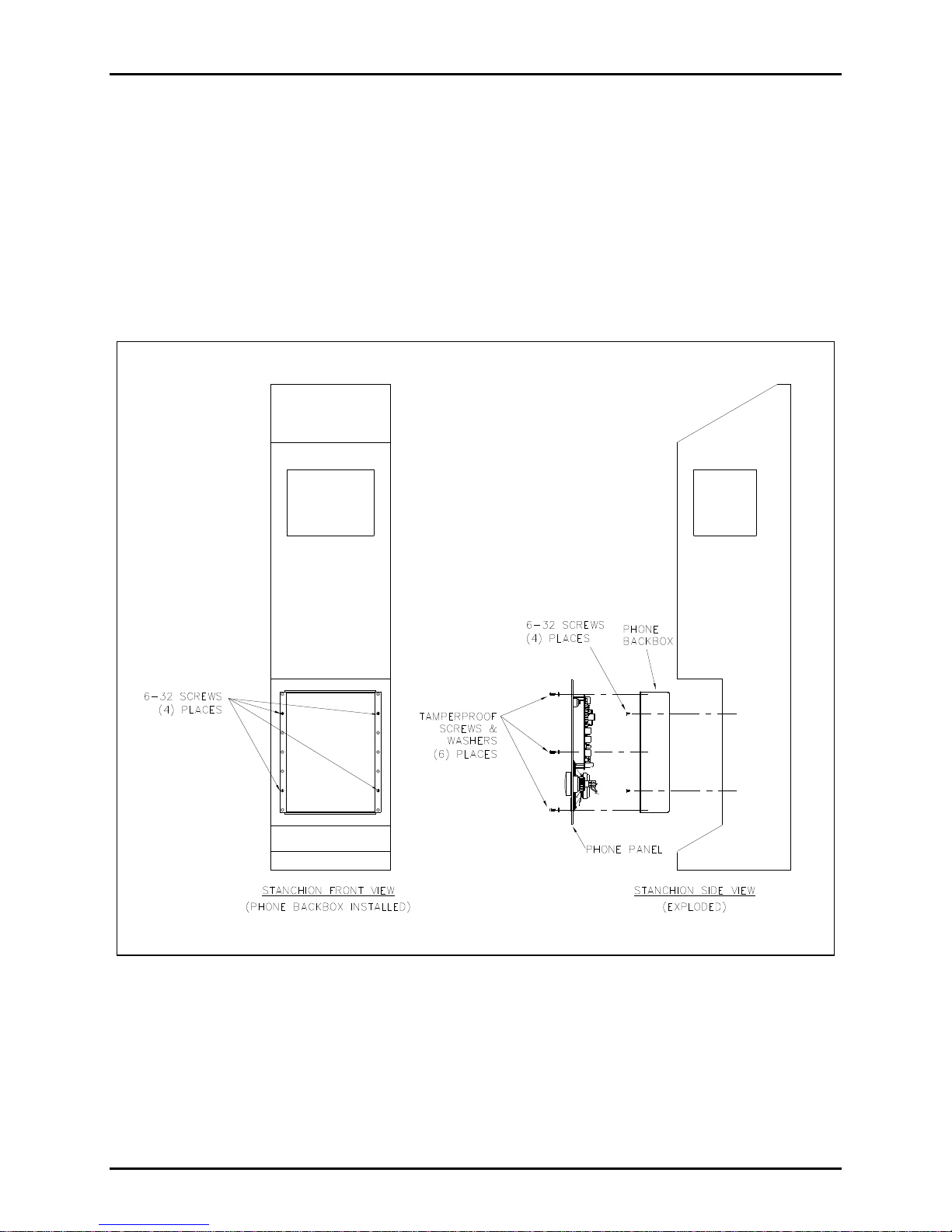

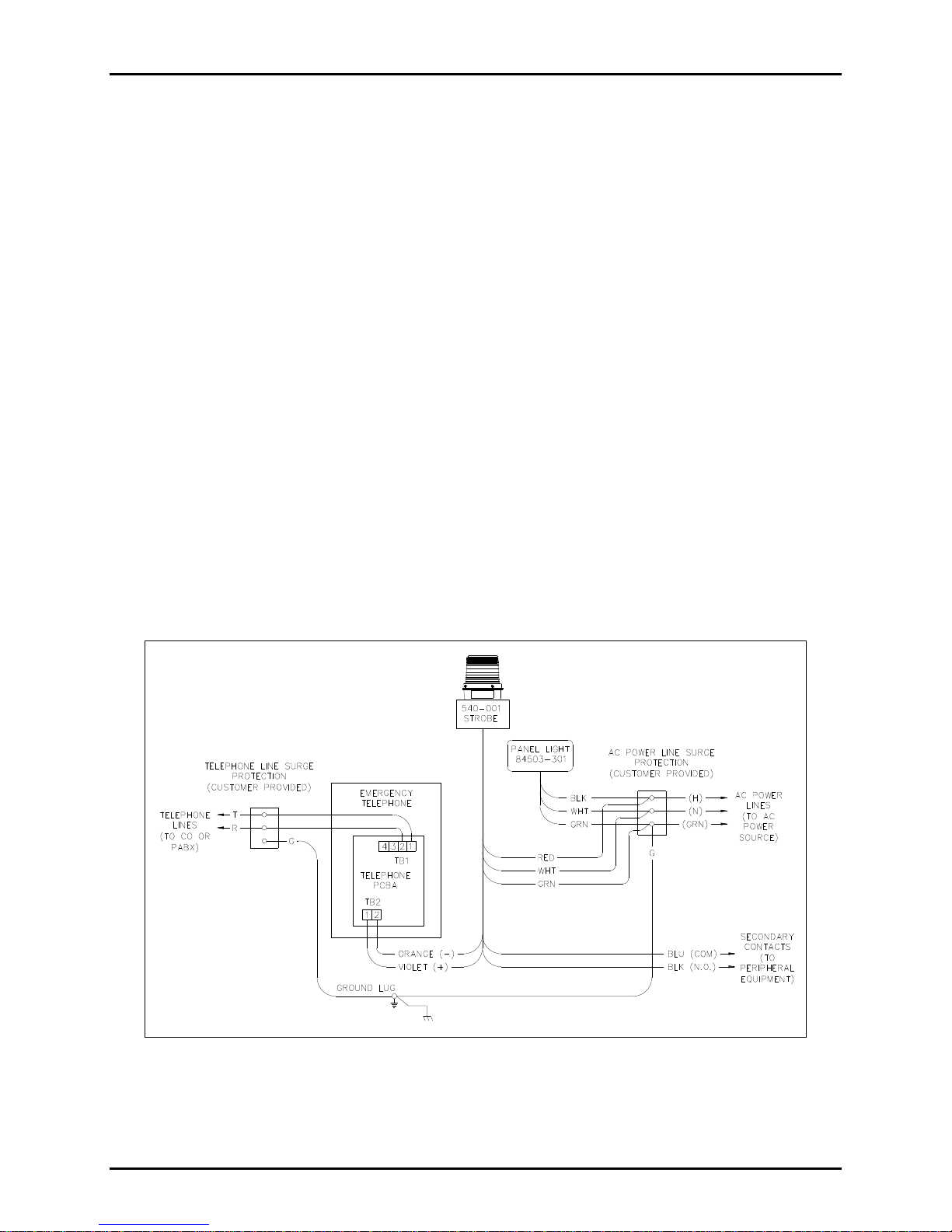

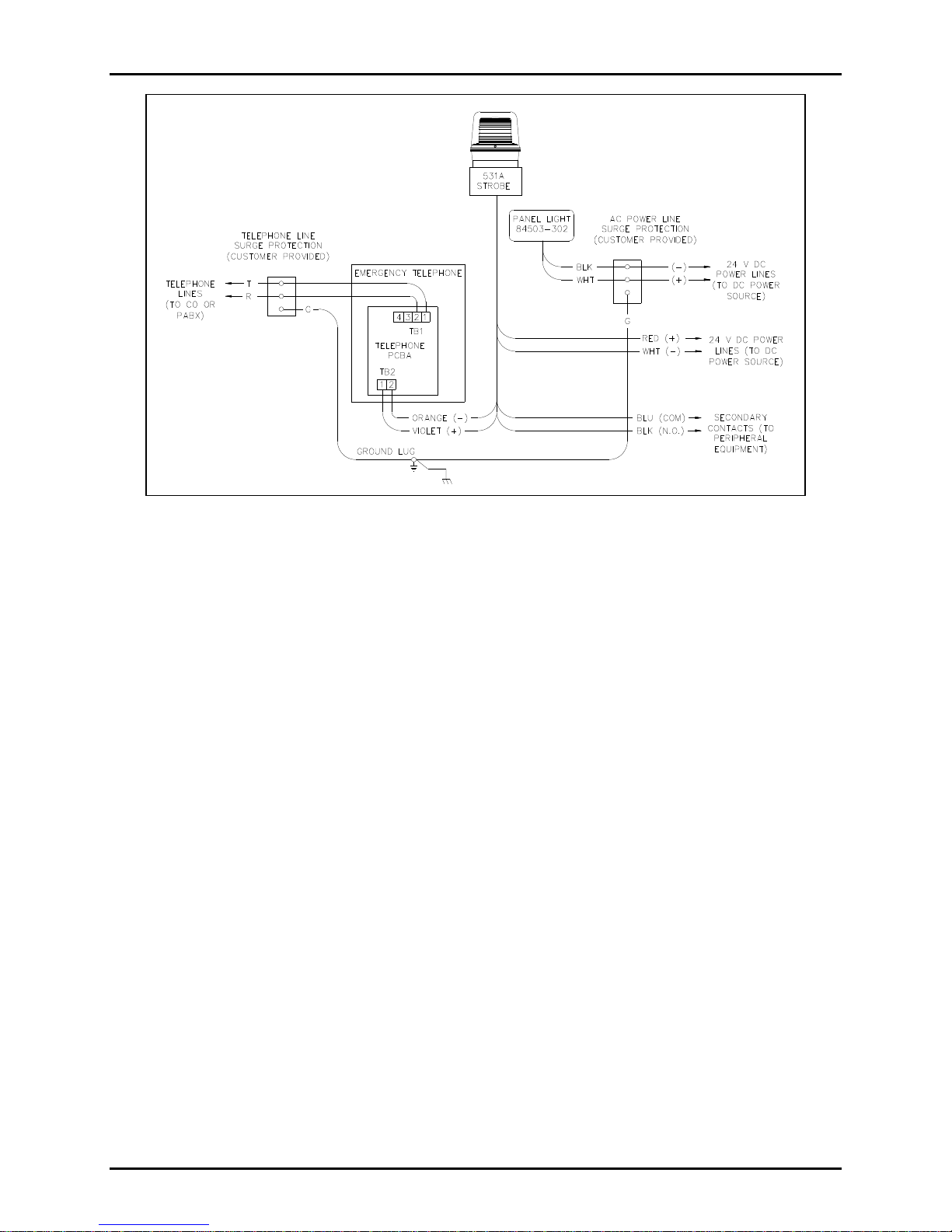

The Model 234WM-202 Wall-Mount Stanchion Assembly is part of a completely integrated emergency

communications station and is designed to house a GAI-Tronics Model 39xor 27xSeries Flush-Mount

Telephone and a Model 540-001or 531A Strobe (each sold separately). The stanchion is a simple,

attractive, yet highly visible unit measuring 40.5 inches (1.03 meters) tall.

GAI-Tronics enhanced emergency telephones are designed for isolated high-risk areas requiring

emergency communications equipment. Emergency telephone users simply press the clearly labeled

emergency push button for immediate connection to a user-programmed central security telephone

number.

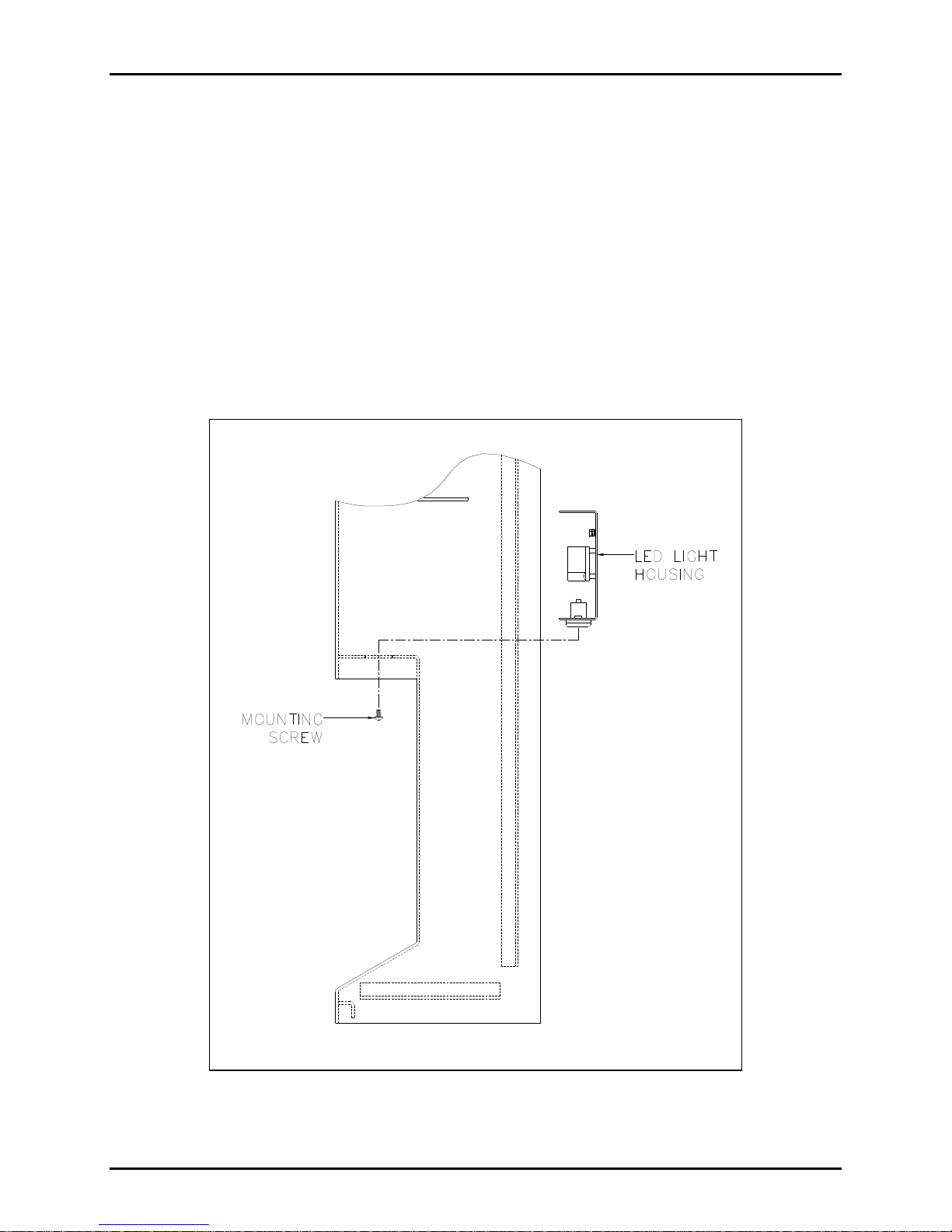

The strobe creates added visibility to emergency telephone locations by providing a constant-on lamp that

automatically flashes when the emergency button is pressed. The telephone is also highly visible; a light

mounted in the stanchion shines on the front of the telephone to illuminate the telephone for nighttime

use.

The Model 234WM-202 Wall-Mount Stanchion Assembly consists of the Model 84505-202 Wall-Mount

Stanchion and the Model 84503-30xPanel Light Assembly (each packaged separately). The strobe and

the emergency telephone are purchased and packaged separately.