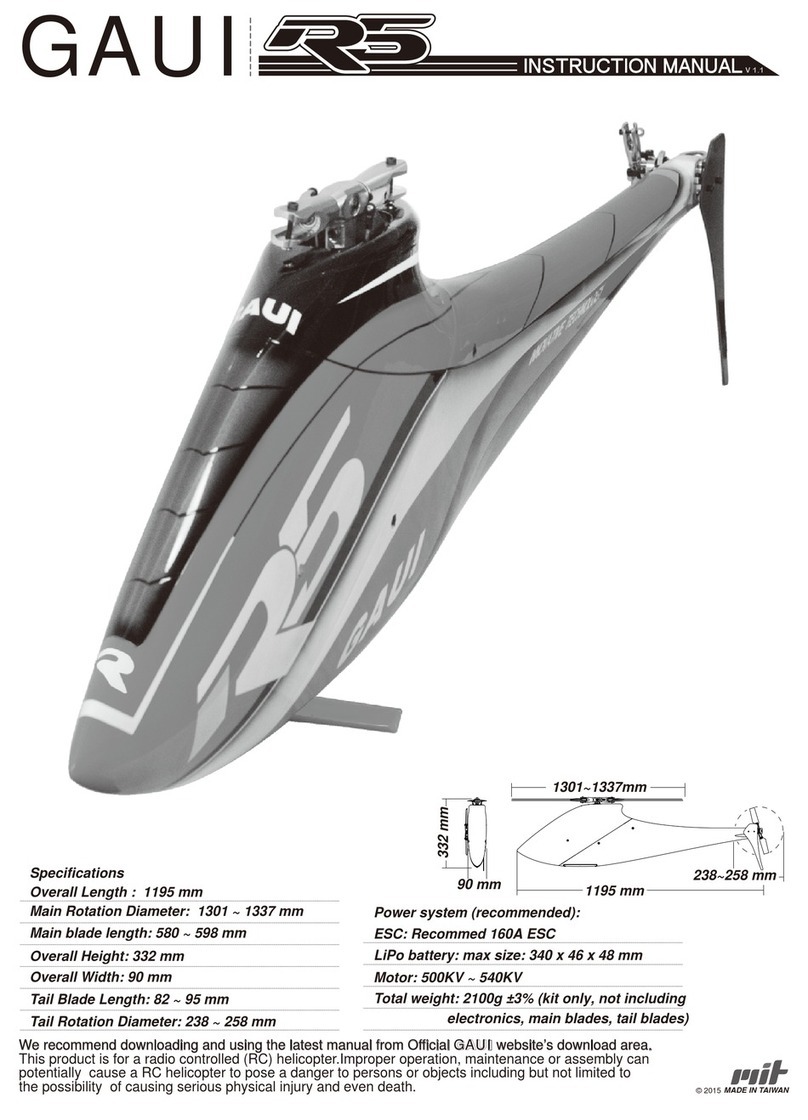

Tail servo and the heading hold gyro setup

1. Install the Gyro and the tail servo.

2. Connect the tail pushrod to the servo.

Make sure the servo arm is 90 degrees

to the tail pushrod. The ball link

should be set at the second hole on

the servo arm (as shown on left).

3. Slide the servo mount and the tail

servo along the tail boom until the

tail pitch lever is parallel to the

tail output shaft or slightly forward.

Important:

Do not touch the

tail pitch lever

mount and the

tail rotor hub.

4. Set the Gyro limitproperly, make sure the

tail pitch yoke do not touch the tail pitch

lever mount and the tail rotor hub when the

tail servo moves to the left and the right

maximum travel volumn. If the Gyro you used

do not have the function of Limit , set the

function of ATV / End Point / Travel Adjust

on transmitter to adjust the proper travel

volumn of the tail servo.

5. If the tail oscillates or wags at less than 60%

gain,you will need to move the ball link to the

hole which is closer to the serve Gyro limit

properly. The ideal gain setting is around 70%.