Page 1-1

Operating Instructions 27C

Your safety, as well as the safety of others is

important. Before you install or use the machine,

read and follow all the safety notices carefully in

this chapter. In this instruction manual, and on the

laminator, you will find important safety notices

regarding the laminator. Read all of the instructions

and save these instructions for further use.

The safety alert symbol precedes each

safety notice in this manual. The symbol indicates a

potential personal safety hazard to you or others, as

well as laminator or property damage.

This safety alert symbol indicates a potential

electrical shock. It warns you to not open the

laminator and expose yourself to hazardous voltage.

The following warnings are found on the 27C

laminator.

This safety notice means that you could be seriously

hurt or killed if you open the laminator and expose

yourself to hazardous voltage.

This safety notice means that your fingers and

hands could be trapped and crushed in the rollers.

Clothing, jewelry and long hair could be caught in the

rollers and pull you into them.

WARNINGS

Do not attempt to service or repair the

laminator.

Do not connect the laminator to an electrical

supply or attempt to operate the laminator

until you have completely read these

instructions. Maintain these instructions in a

convenient location for future reference.

To guard against injury, the following safety

precautions must be observed when installing

and using the laminator.

Failure to observe these warnings could result in

severe bodily damage or death.

GENERAL

Keep hands, long hair, loose clothing, and

articles such as necklaces or ties, away from

the front of the rollers to avoid entanglement

and entrapment

Do not use the laminator for other than its

intended purpose.

Do not place the laminator on an unstable

cart, stand or table. An unstable surface may

cause the laminator to fall resulting in serious

bodily injury. Avoid quick stops, excessive

force and uneven floor surfaces when moving

the laminator on a cart or stand.

Do not defeat or remove electrical and

mechanical safety equipment such as

interlocks, shields and guards.

Do not insert objects unsuitable for lamination

or expose the equipment to liquids.

•

•

•

•

•

•

•

•

1. SAFETY

ADVERTENCIA

!

Riesgo de choque

eléctrico

No abra:

Adentro no hay

piezas reparables

por el usuario.

Mantenimiento

solamente por

personal calificado.

ATTENTION

!

Risque de

secousse

électrique.

Ne pas ouvrir:

Pas de pièces

réparables par

l'utilisateur.

Entretien

seulement par

personnel qualifié.

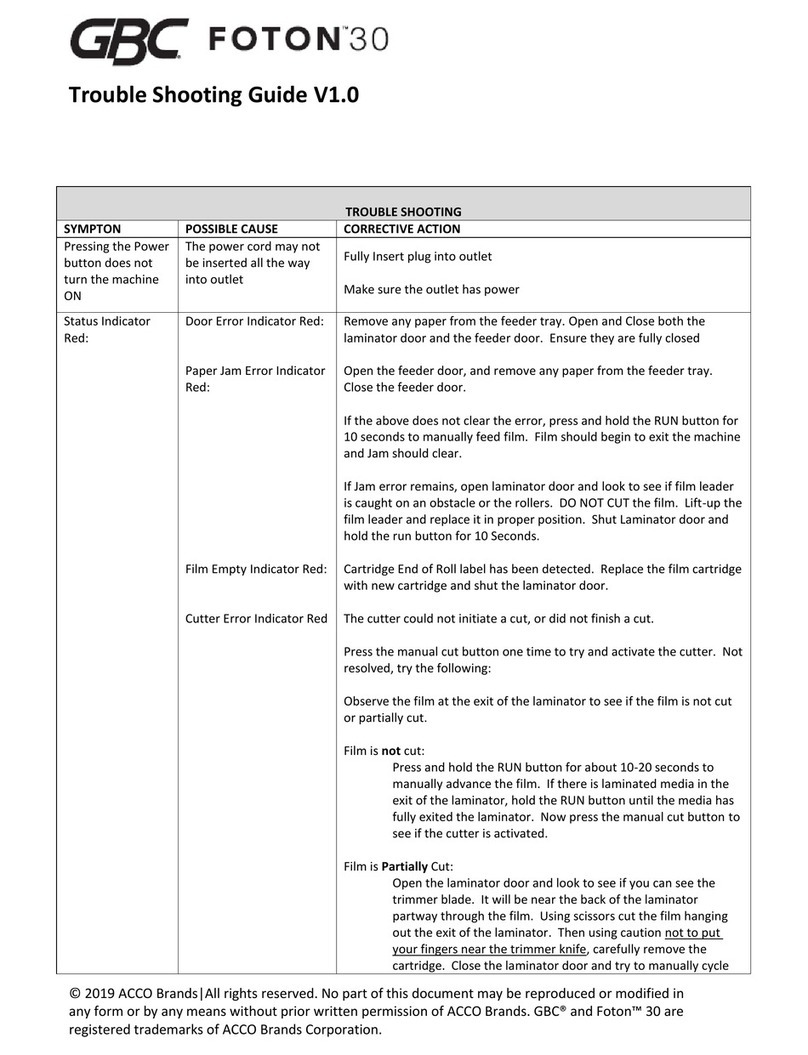

WARNING

!

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicing to

qualified service

personnel.

CAUTION

ATTENTION

CUIDADO

PUNTO DE

PINCHAMIENTO

Keep hands and

fingers away.

Mantener manos

y

dedos a distancia.

Tenir mains et

doigts a l'écat.

PINCH POINT

between rollers.

POINT DE

PINCEMENT

entre les rouleaux.

entre rodillos.