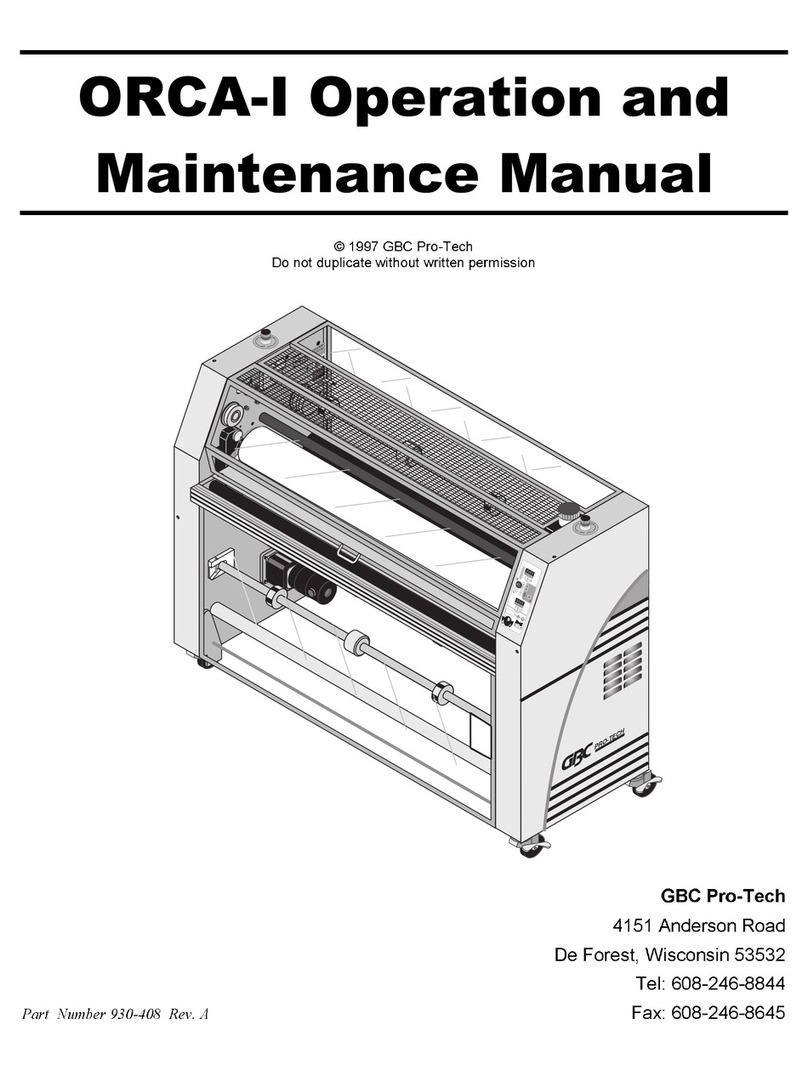

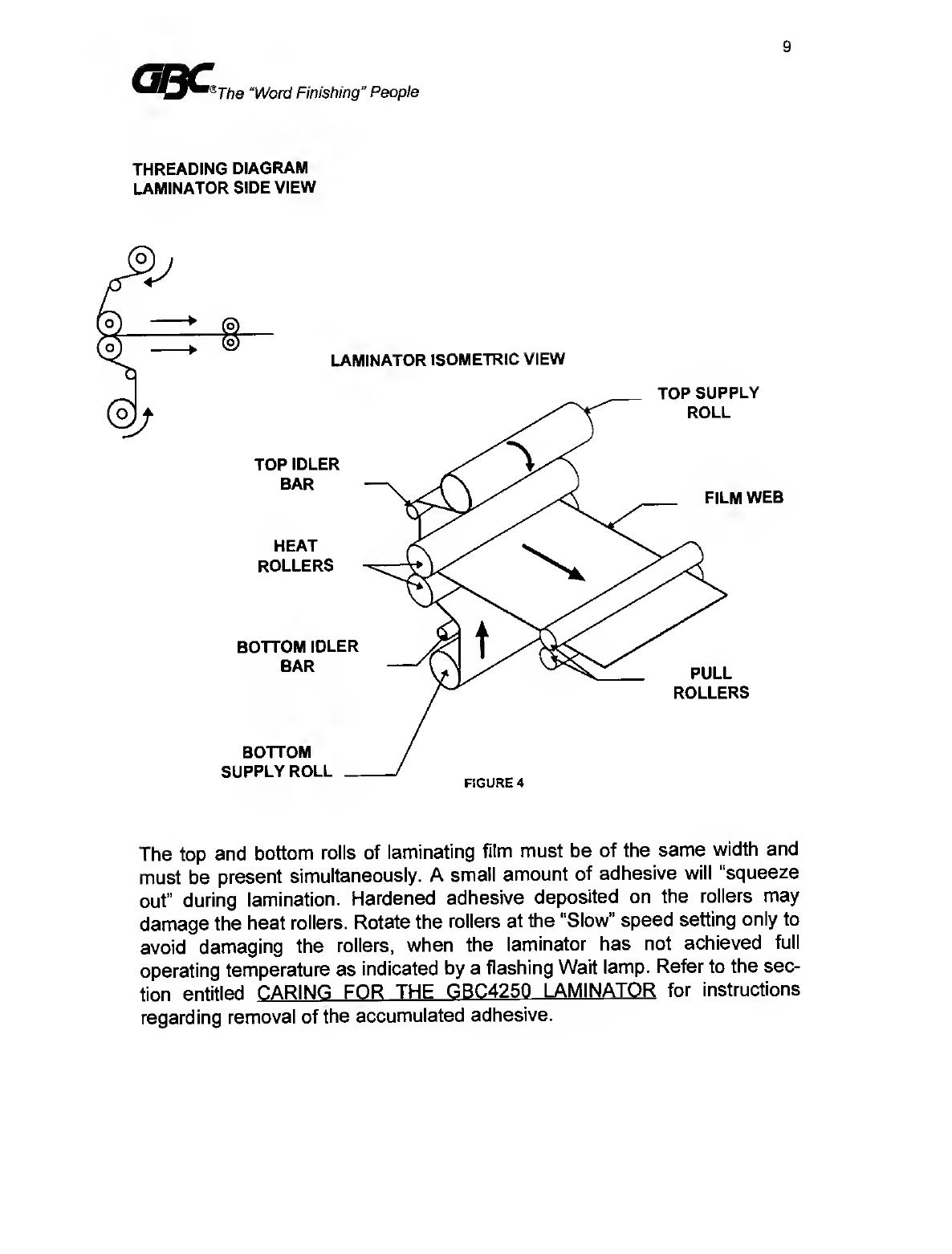

GBC GBC4250 User manual

Other GBC Laminator manuals

GBC

GBC 930-073 User manual

GBC

GBC FALCON 60 C User manual

GBC

GBC FUSION 3000L User manual

GBC

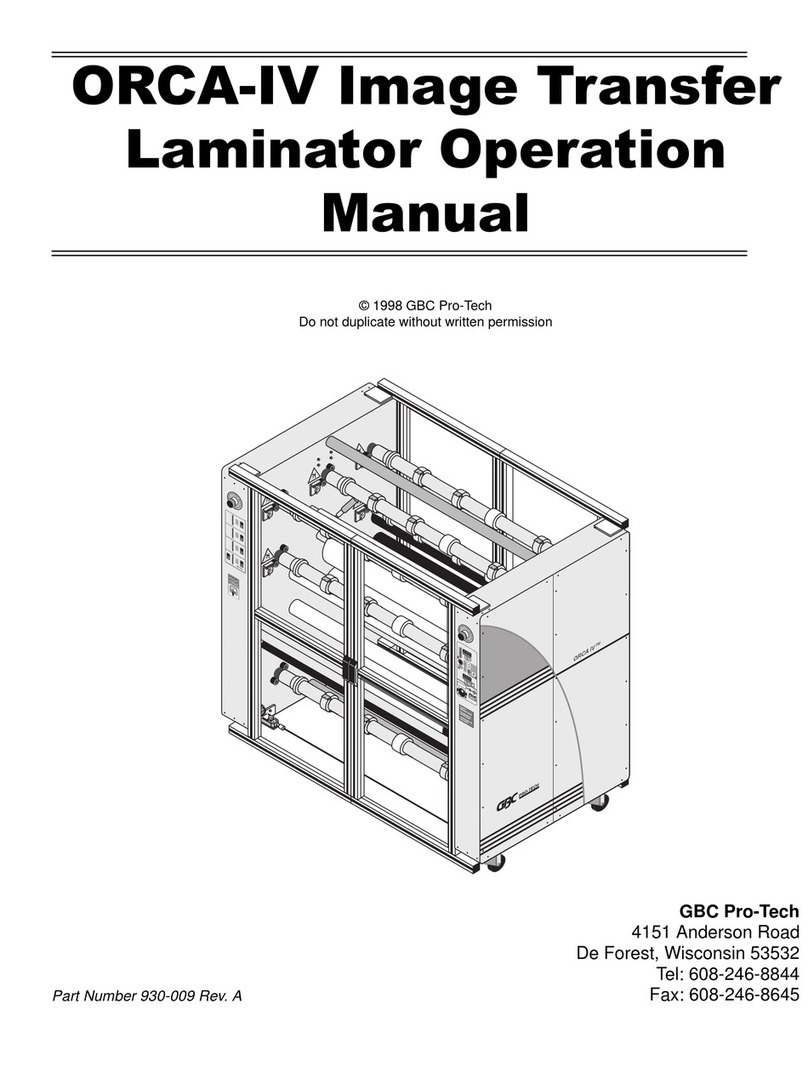

GBC ORCA-IV User manual

GBC

GBC HEATSEAL H800 PRO-R User manual

GBC

GBC FOTON 30 Automated Laminator User manual

GBC

GBC FUSION 1000L A4 Instruction Manual

GBC

GBC Arctic Titan 165 User manual

GBC

GBC HeatSeal H520 User manual

GBC

GBC Artic Titan 1040 User manual