2 MIFII Digital Feeder Relay GEK-106237P

TABLE OF CONTENTS

2.16.10 APPROVALS ....................................................................................................2-30

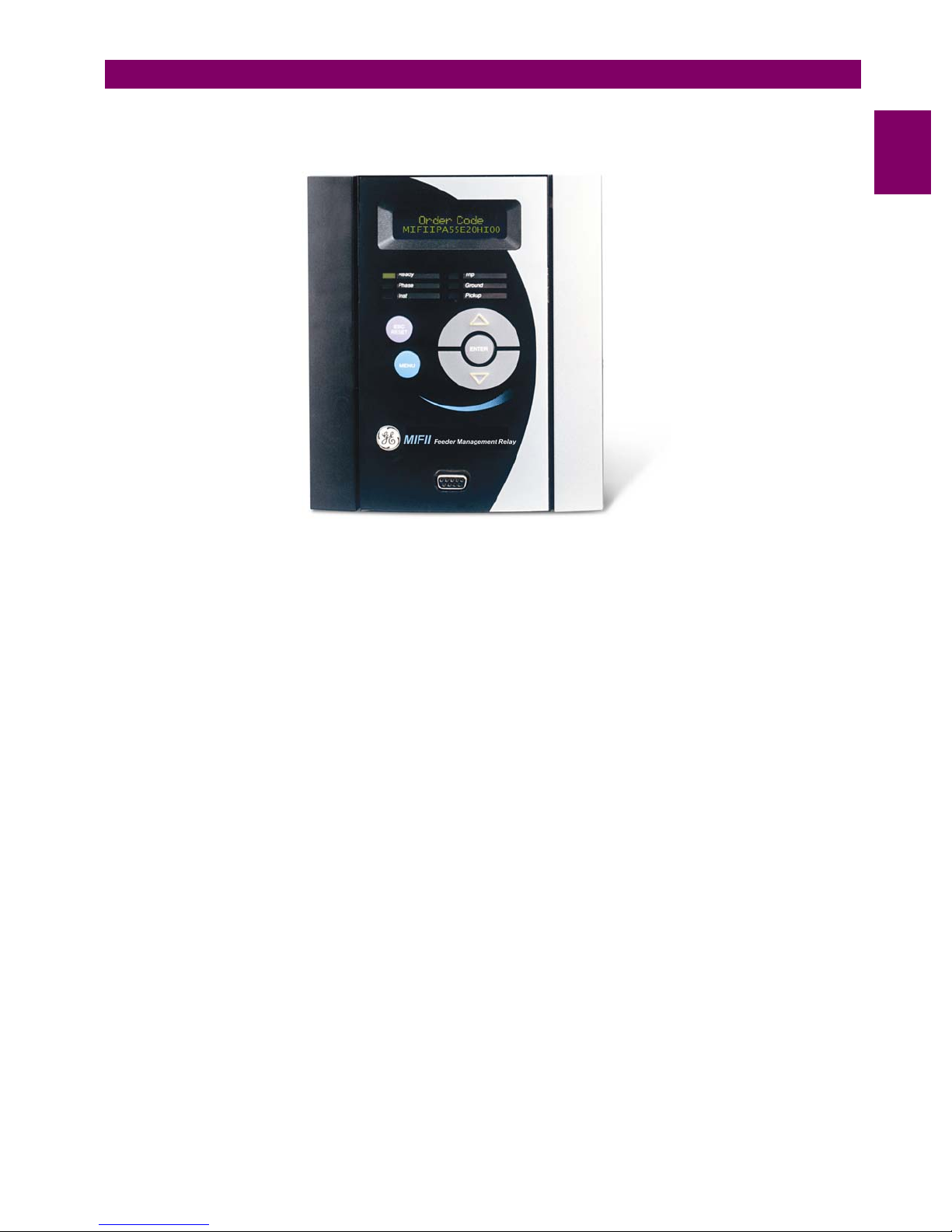

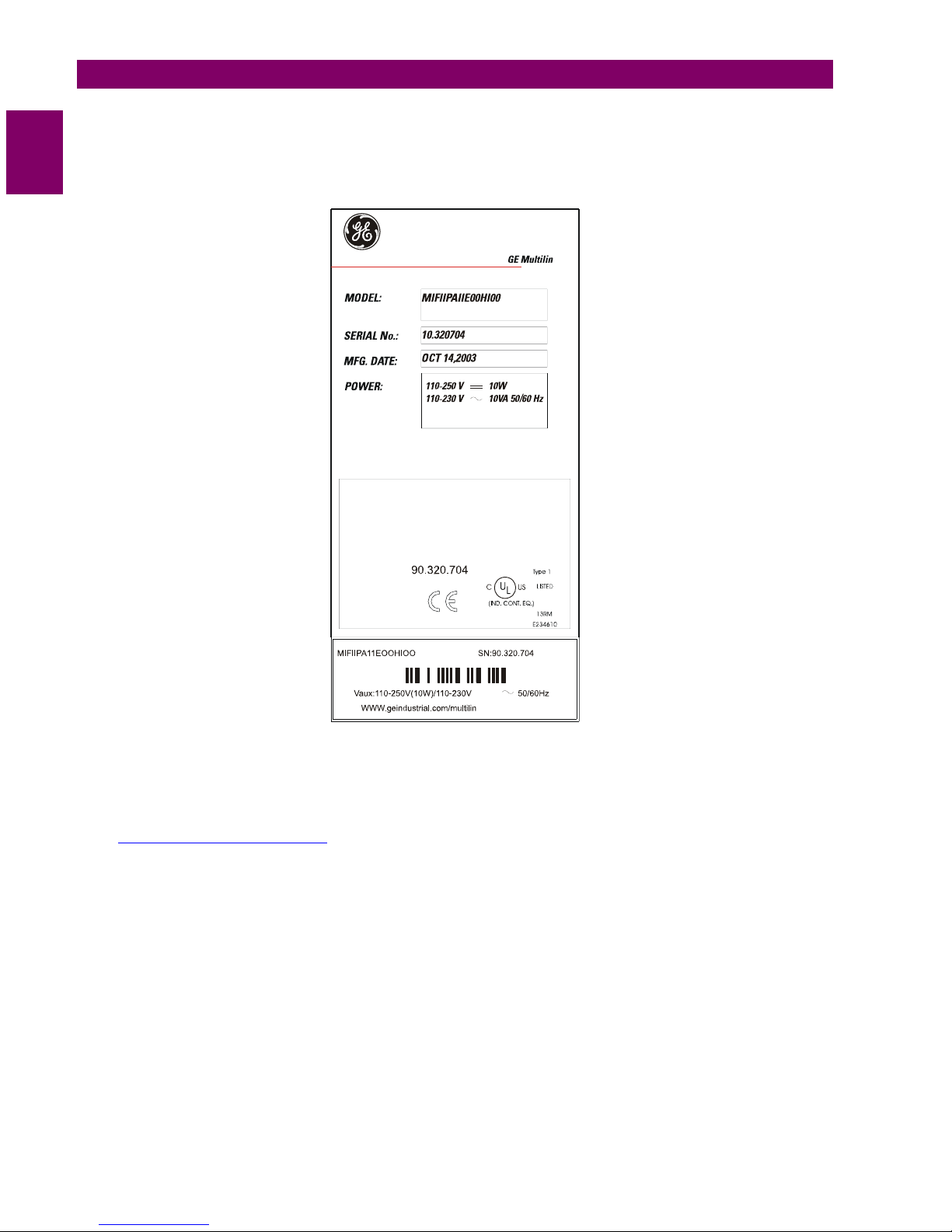

3. HARDWARE 3.1 DESCRIPTION

3.1.1 MECHANICAL DESCRIPTION..........................................................................3-1

3.1.2 MOUNTING ........................................................................................................3-2

3.1.3 REAR DESCRIPTION ........................................................................................3-3

3.1.4 TYPICAL WIRING DIAGRAM.............................................................................3-4

3.1.5 CONTROL POWER............................................................................................3-6

3.1.6 AC CURRENT TRANSFORMER INPUTS .........................................................3-7

3.1.7 CONTACT INPUTS / OUTPUTS .......................................................................3-8

3.1.8 OUTPUT CONTACTS CONFIGURATION .........................................................3-9

3.1.9 OUTPUTS ISOLATION ....................................................................................3-10

3.1.10 RS232 FRONT COMMUNICATIONS PORT....................................................3-13

3.1.11 RS485 COMMUNICATIONS PORT .................................................................3-14

4. COMMUNICATIONS 4.1 ENERVISTA MII SETUP SOFTWARE

4.1.1 OVERVIEW ........................................................................................................4-1

4.1.2 STARTING COMMUNICATION..........................................................................4-2

4.1.3 MAIN SCREEN...................................................................................................4-2

4.2 FILE

4.2.1 NEW ...................................................................................................................4-3

4.2.2 OPEN..................................................................................................................4-3

4.2.3 SETTINGS FILE CONVERTER..........................................................................4-4

4.2.4 PROPERTIES.....................................................................................................4-4

4.2.5 GET INFO FROM RELAY ..................................................................................4-5

4.2.6 SEND INFO TO RELAY .....................................................................................4-5

4.2.7 PRINT SETUP ....................................................................................................4-5

4.2.8 PRINT PREVIEW ...............................................................................................4-5

4.2.9 PRINT .................................................................................................................4-6

4.2.10 CLOSE................................................................................................................4-6

4.3 SETPOINT

4.3.1 SETTINGS..........................................................................................................4-7

4.3.2 MAIN SETTINGS................................................................................................4-8

4.3.3 ADVANCED SETTINGS.....................................................................................4-8

4.3.4 RELAY CONFIGURATION.................................................................................4-9

4.3.5 LOGIC CONFIGURATION ...............................................................................4-11

4.3.6 DATE /TIME......................................................................................................4-12

4.4 ACTUAL

4.4.1 ACTUAL VALUES ............................................................................................4-13

4.4.2 EVENT RECORDER ........................................................................................4-14

4.4.3 WAVEFORM CAPTURE ..................................................................................4-15

4.5 OPERATIONS

4.6 COMMUNICATION

4.6.1 COMPUTER .....................................................................................................4-17

4.6.2 TROUBLESHOOTING......................................................................................4-20

4.6.3 UPGRADE FIRMWARE VERSION ..................................................................4-21

4.7 VIEW

4.7.1 TRACES ...........................................................................................................4-25

4.7.2 MODBUS MEMORY MAP ................................................................................4-26

4.7.3 LANGUAGES ...................................................................................................4-27

5. SETTINGS 5.1 SETTINGS STRUCTURE

5.2 MAIN SETTINGS

5.2.1 GENERAL SETTINGS........................................................................................5-2

5.2.2 PHASE / GROUND TOC SETTINGS (51P / 51G) ( ..........................................5-3