GE Druck DPI612 User manual

Other GE Test Equipment manuals

GE

GE Druck DPI 620-IS User manual

GE

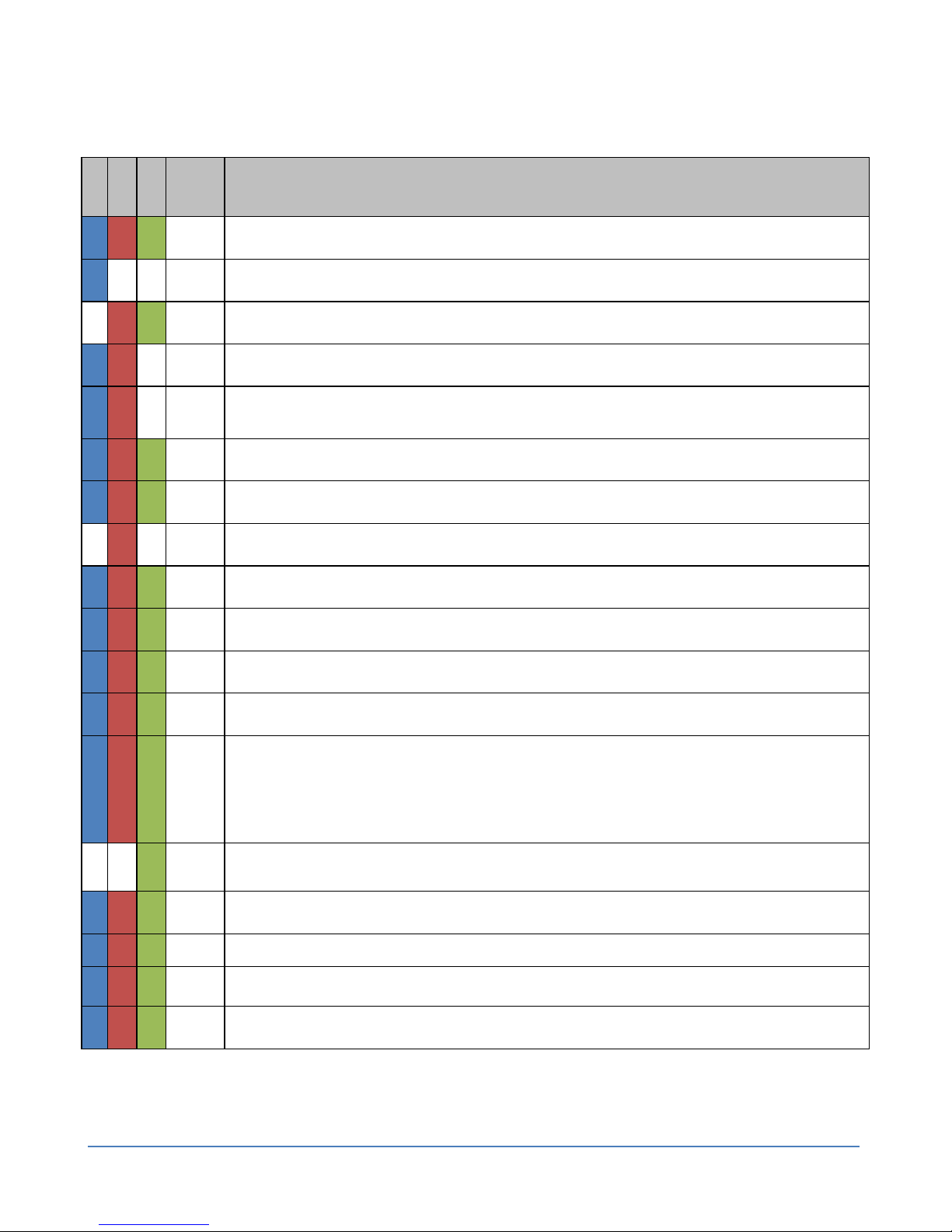

GE Druck DPI 620 User manual

GE

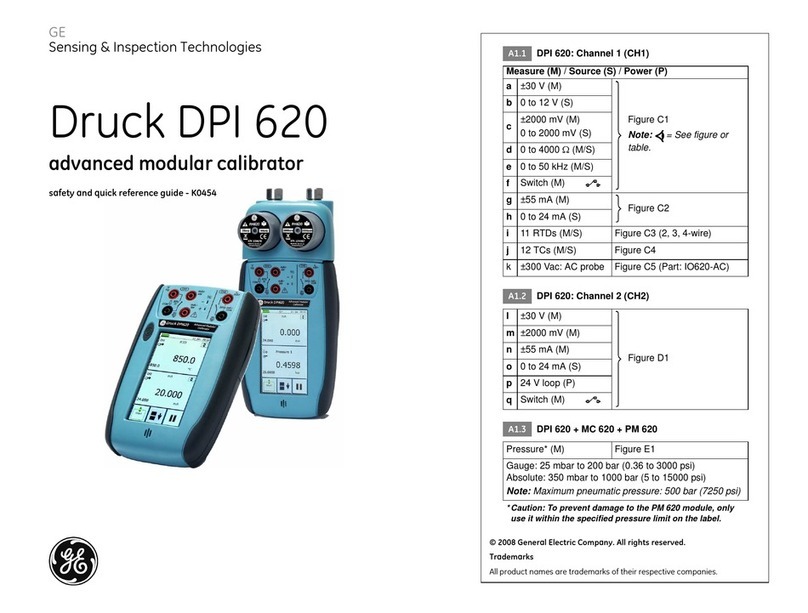

GE PACE5000 Use and care manual

GE

GE EntelliGuard G User manual

GE

GE Druck DPI 841 User manual

GE

GE Mentor EM User manual

GE

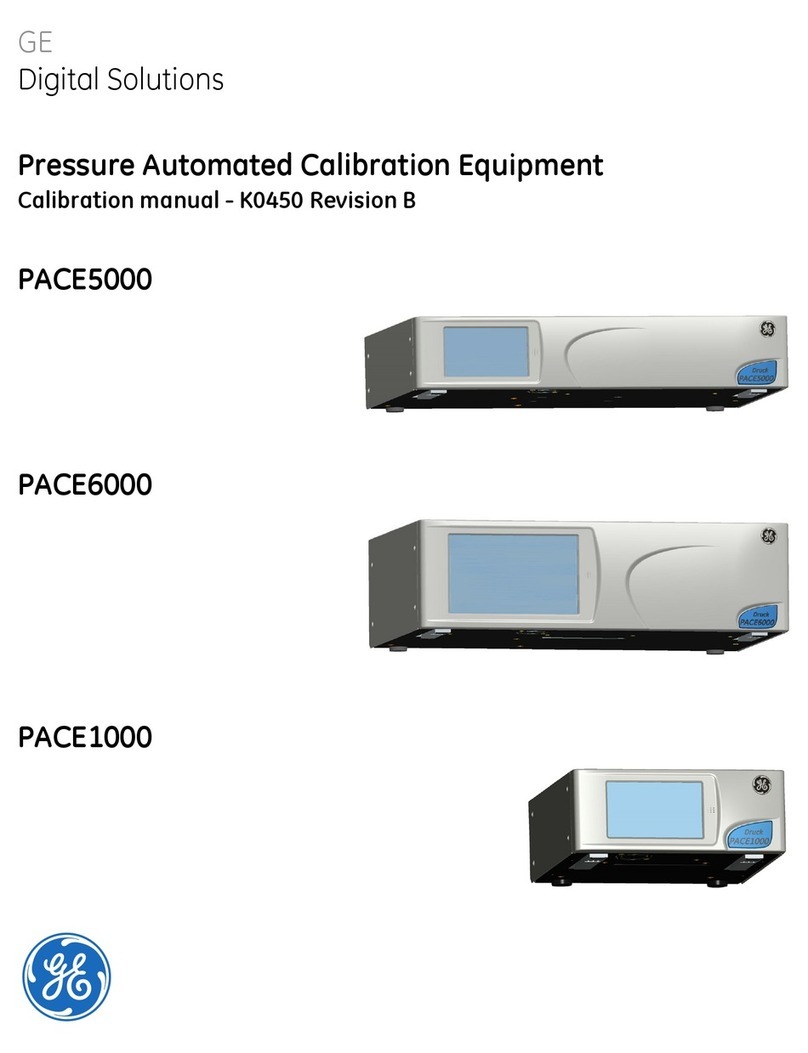

GE Druck PC6-IDOS User manual

GE

GE PACE Series User manual

GE

GE Druck DPI 821 User manual

GE

GE MicroVersaTrip TVTS1 User manual

GE

GE Druck ADTS 2 Series User manual

GE

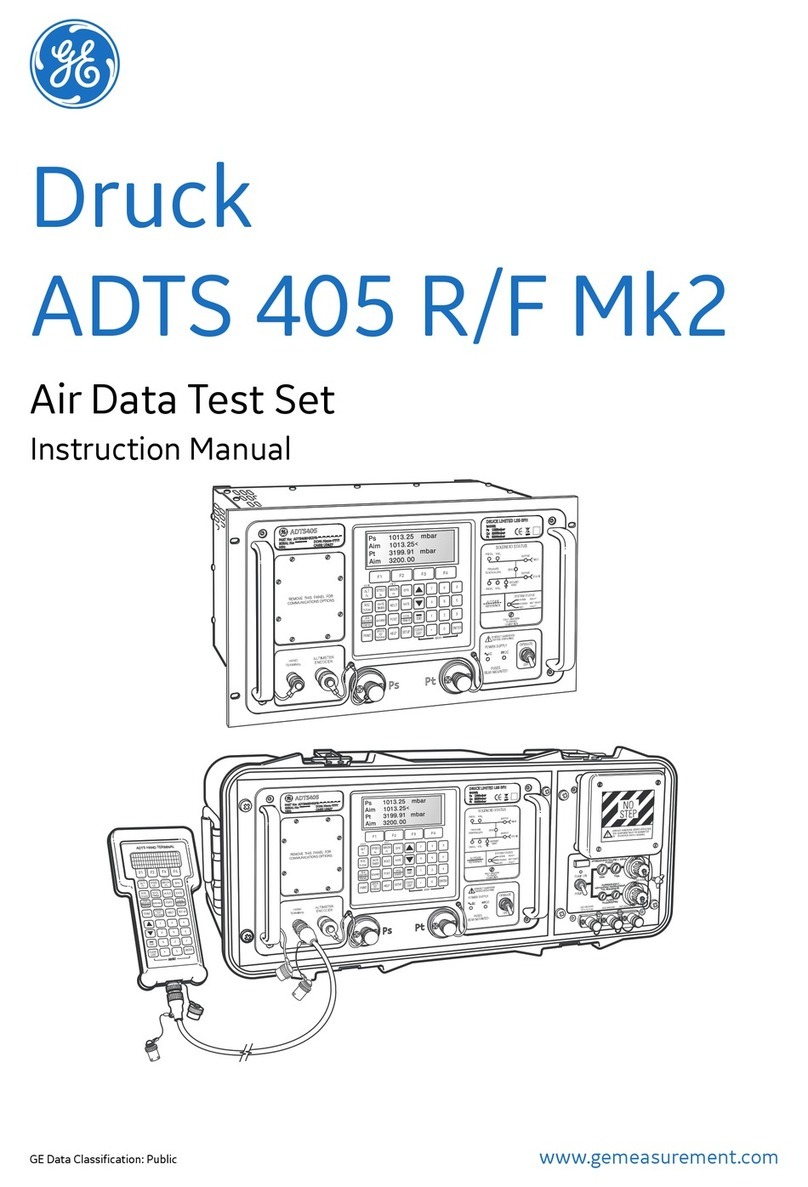

GE Druck ADTS 405 R/F Mk2 User manual

GE

GE Druck DPI611 Operating and maintenance instructions

GE

GE POWER-BREAK TAK-TS1 User manual

GE

GE Druck ADTS 542F Setup guide

GE

GE Druck DPI 620 User manual

GE

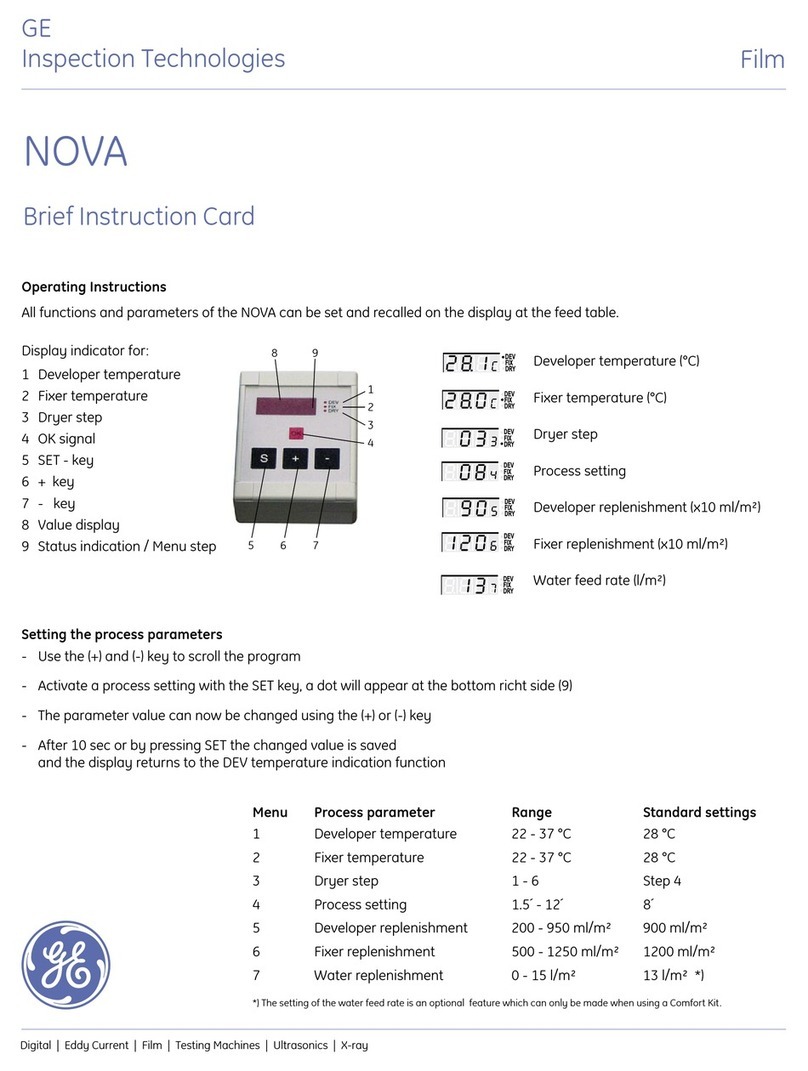

GE NOVA Parts list manual

GE

GE ADTS 405F Mk2 Setup guide

GE

GE K0341 User manual

GE

GE EntelliGuard User manual