Table of content Page

1IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................................6

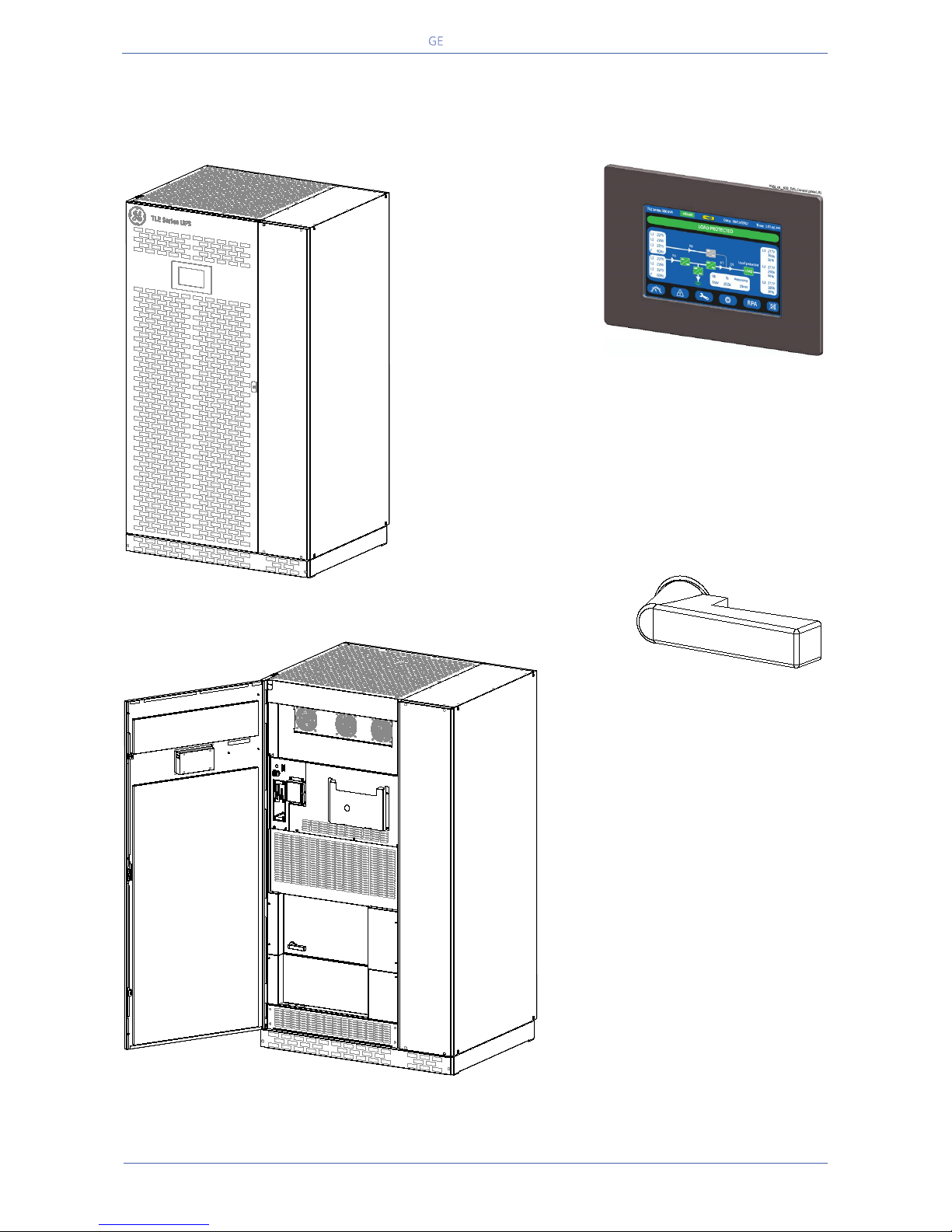

2LAYOUT..................................................................................................................................................................................9

2.1 LAYOUT TLE SERIES 160 - 220 - 225 - 250...............................................................................................................................................................9

2.2 LAYOUT TLE SERIES 300 - 400 - 500........................................................................................................................................................................ 10

3INTRODUCTION .................................................................................................................................................................11

4DESCRIPTION......................................................................................................................................................................12

4.1 BLOCK DIAGRAM AND MAIN ELEMENTS................................................................................................................................................................ 13

4.2 OPERATION MODES......................................................................................................................................................................................................... 14

4.2.1 Normal VFI Operation Mode (Voltage Frequency Independent)...................................................................................................................................... 14

4.2.2 eBoost™ Operation Mode (option).................................................................................................................................................................................................. 14

4.2.3 Utility Failure Operation....................................................................................................................................................................................................................... 15

4.2.4 Utility Recovery Operation.................................................................................................................................................................................................................. 15

4.2.5 Automatic Bypass................................................................................................................................................................................................................................... 16

4.3 RPA PARALLEL SYSTEM OPERATION ........................................................................................................................................................................ 17

4.3.1 Introduction to the RPA Parallel System...................................................................................................................................................................................... 17

4.3.2 Features of RPA Parallel System...................................................................................................................................................................................................... 18

4.3.3 System control.......................................................................................................................................................................................................................................... 18

4.3.4 Synchronization ....................................................................................................................................................................................................................................... 18

4.3.5 Load sharing.............................................................................................................................................................................................................................................. 18

4.3.6 IEMi Operation Mode (option)............................................................................................................................................................................................................ 19

4.4 UPS PARALLELED ON THE SAME BATTERY............................................................................................................................................................ 20

4.5 SERVICE AND TECHNICAL SUPPORT........................................................................................................................................................................ 21

4.6 WARRANTY ......................................................................................................................................................................................................................... 21

4.7 RECYCLING INSTRUCTIONS ......................................................................................................................................................................................... 22

5CONTROL PANEL ...............................................................................................................................................................23

5.1 CONTROL PANEL .............................................................................................................................................................................................................. 23

6LCD SCREEN .......................................................................................................................................................................24

6.1 HOME SCREEN................................................................................................................................................................................................................... 24

6.1.1 Description of the selection keys .................................................................................................................................................................................................... 25

6.1.2 Description of the signaling LEDs ................................................................................................................................................................................................... 26

6.2 MEASURES........................................................................................................................................................................................................................... 29

6.3 EVENTS ................................................................................................................................................................................................................................. 33

6.3.1 Events (alarms and messages)......................................................................................................................................................................................................... 35

6.3.2 Alarms list.................................................................................................................................................................................................................................................... 35

6.3.3 Messages list ............................................................................................................................................................................................................................................. 40

6.4 SETUP .................................................................................................................................................................................................................................... 43

6.5 COMMANDS........................................................................................................................................................................................................................ 49

6.6 RPA PARALLEL SYSTEM.................................................................................................................................................................................................. 53

7OPERATION.........................................................................................................................................................................55

7.1 PROCEDURES FOR SINGLE TLE SERIES 160 - 500.............................................................................................................................................. 56

7.1.1 Initial start-up of the TLE Series 160 - 500.................................................................................................................................................................................. 56

7.1.2 Complete UPS shut-down................................................................................................................................................................................................................... 60

7.1.3 Restore to normal operation after “System shutdown” with Load not supplied .................................................................................................... 61

7.1.4 Restore to normal operation after “EPO - Emergency Power Off” with Load not supplied ............................................................................... 63

7.2 PROCEDURES SINGLE TLE SERIES 160 - 500 FUNCTIONING AS FREQUENCY CONVERTER............................................................. 65

7.2.1 Initial Start-up of the TLE Series 160 - 500 as frequency converter.............................................................................................................................. 65

7.2.2 Complete shut-down of the TLE Series 160 - 500 as frequency converter ............................................................................................................... 69

7.2.3 Restore to normal operation after “System shutdown” with Load not supplied .................................................................................................... 70

7.2.4 Restore to normal operation after “EPO - Emergency Power Off” with Load not supplied ............................................................................... 72

7.3 PROCEDURES FOR TLE SERIES 160 - 500 PARALLEL SYSTEM....................................................................................................................... 74

7.3.1 TLE Series 160 - 500 Parallel System start-up.......................................................................................................................................................................... 74

7.3.2 Separate a UPS unit from the Redundant Parallel System ................................................................................................................................................ 79

7.3.3 Reconnect a UPS unit to Redundant Parallel System........................................................................................................................................................... 81

7.3.4 Complete Parallel System shut-down........................................................................................................................................................................................... 83

7.3.5 Restore to normal operation after “System shutdown” with Load not supplied .................................................................................................... 84

7.3.6 Restore to normal operation after “EPO - Emergency Power Off” with Load not supplied............................................................................... 86

8OPTIONS..............................................................................................................................................................................88

8.1 CONNECTIVITY OPTIONS............................................................................................................................................................................................... 88

8.2 OPTIONS IN UPS CABINET............................................................................................................................................................................................ 88

9MAINTENANCE ...................................................................................................................................................................89

9.1 MAINTENANCE .................................................................................................................................................................................................................. 89

9.1.1 Service check ............................................................................................................................................................................................................................................ 89

9.1.2 Fans and ventilation.............................................................................................................................................................................................................................. 89

9.1.3 Other components with limited lifetime...................................................................................................................................................................................... 89

9.1.4 Battery .......................................................................................................................................................................................................................................................... 90

9.1.5 UPS room conditions and temperature....................................................................................................................................................................................... 90

9.1.6 Preventive maintenance program ................................................................................................................................................................................................. 90

10 NOTES..................................................................................................................................................................................91

10.1 NOTES FORM...................................................................................................................................................................................................................... 91