4 Packing list

4.1 Unpacking

Please check during the unpacking process that all

parts have been delivered completely and undamaged.

Make sure to remove all parts from the packaging

material. Claims for damages caused during transport

can only be asserted, if the carrier is informed without

delay. Please prepare a survey report and send it back

to the supplier along with the damaged part.

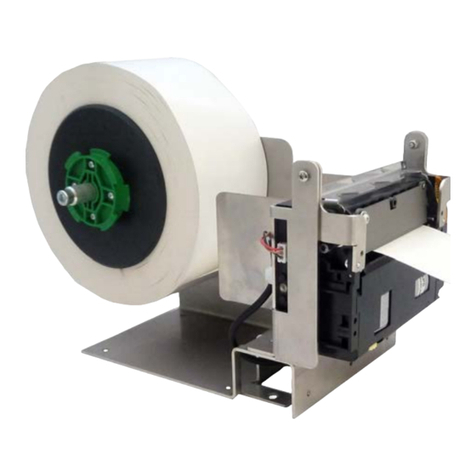

Standard versions of the thermal printers

in 2" or 3" width for OEM are supplied without

accessories. Please order those separately.

All current documents are listed on the Internet at

www.oem-printer.com/info.

User manuals for the GeBE thermal printer controllers

installed in the printer can be requested from GeBE via

4.2 Standard accessories:

• 1 roll of thermal paper matching the printer width

• interface cable for RS232 or USB

• power supply

• fastening screws

4.2.1 Standard paper

A=outside coating, WR=water resistent:

• GPR-T01-060-070-025-080A/WR:

50 pcs. thermal paper rolls w: 60 mm, th: 80 µm,

diameter: 70 mm, core diameter: 25 mm, life: 7 years

• GPR-T01-082-070-025-080A/WR:

50 pcs. thermal paper rolls w: 82 mm, th: 80 µm,

diameter: 70 mm, core diameter: 25 mm, life: 7 years

Which thermal paper is suitable?

The printers are specified for 51-61 mm and 60-82 mm

(+/- 0,5 mm) paper widths, up to 200 µm paper

thickness.

Other papers may cause failures:

Thermal papers that are resistant against water, grease,

or alcohol are available for special applications. We will

gladly assist you in selecting the right thermal paper for

your purposes.

Which side of the thermal paper can be printed on?

When in doubt, try the finger nail test: Quickly run the

tip of a finger nail across the paper, applying pressure.

The friction heat will cause blackening on the thermo

sensitive side.

4.2.2 Cables

• GKA-245-1-500

power supply, 2 single wires, 1.0 mm2,

500 mm, one end open, wire end sleeves

• GKA-406-2-1000

round cable, 1,000 mm, 5pin to JST plug at

controller, with 9 pin SUB-D socket to RS232

interface at the host (PC)

• GKA-570-USB-FS-MOLEX-2,0 m

cable USB to Molex, length 2.0 m, for full speed

transmission

• GKA-xxx2

Cable Near-Paper-End-Sensor for GPT-4672 with

6pin. plug on socket 6157M06-R

• GKA-xxx3

Cable Near-Paper-End-Sensor for GPT-4673 with

3pin. plug on socket JST-S03-B-XH-A

4.2.3 Power supply

• GNG-24V-6.5A-AC:

open frame power supply 24 V / 6,5 A

4.3 Driver software

Printer controller GCT-4692/4693 is supported by the

following Windows® drivers:

Windows® CE.Net 4.2, 5.0, Windows® 2000, and XP.

The driver software can be downloaded from the

internet: www.oem-printer.com/info