7MSPA-1-AS

POWER & GROUND CHECKGFCI Trips!

1• Verify if the GFCI is properly

connected.

2• If it is not, verify the GFCI wiring

diagram and reconnect it.

If the equipment is connected but nothing seems to work, the power supply

must be defective. Perform the following:

Note that in new installations, GFCI trippings due to miswiring are very common.

If the breaker is properly wired, GFCI trippings can occur when the total amount of current

drawn by the spa exceeds the rating of the breaker. Such an occurrence, however, is very

unlikely since each output of the spa pack is individually fused and fuses will blow before the

GFCI trips.

A current leak to the ground will also make the GFCI trip. If one of the components is faulty

and there is a leak of more than 5 mA, the GFCI will trip to prevent electrocution.

Several different models of GFCIs are available on the market. Note that our illustrations are

generic.

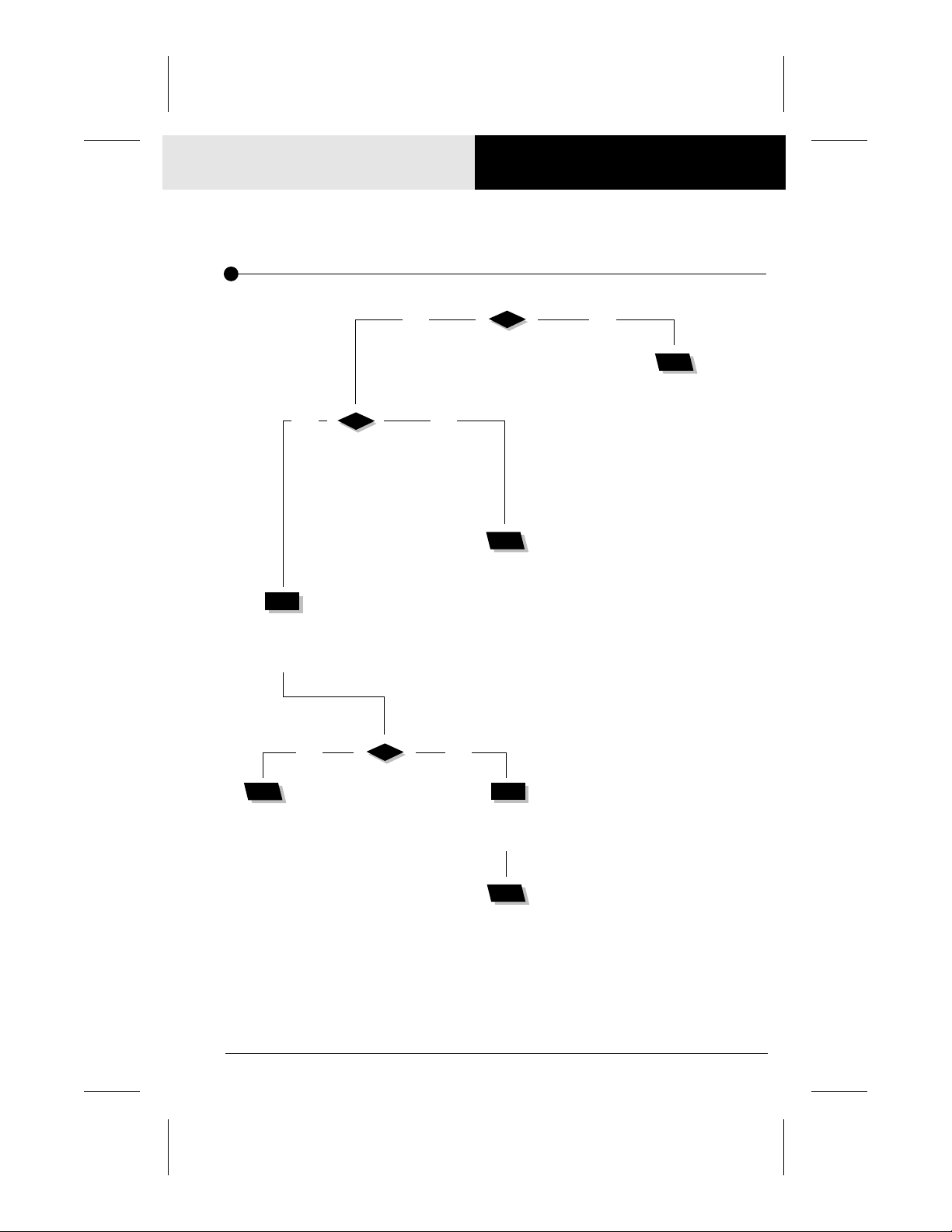

3• If the GFCI is properly connected but

still tripping, disconnect all outputs,

including the two wires of the heater &

the light cord.

4• If the GFCI still trips, replace the

transformer.

5• If the GFCI still trips even after the

transformer has been replaced:

a- Disconnect the power input wires.

If the GFCI still trips, the cable must

be defective.

Call an electrician!

b- If the GFCI stops tripping, replace it.

c- If the GFCI is still tripping, replace

the board referring to the "How to

Replace the Board" section of this

manual.

If it stops tripping, reconnect one com-

ponent at a time until the GFCI starts

tripping. Replace the defective com-

ponent.