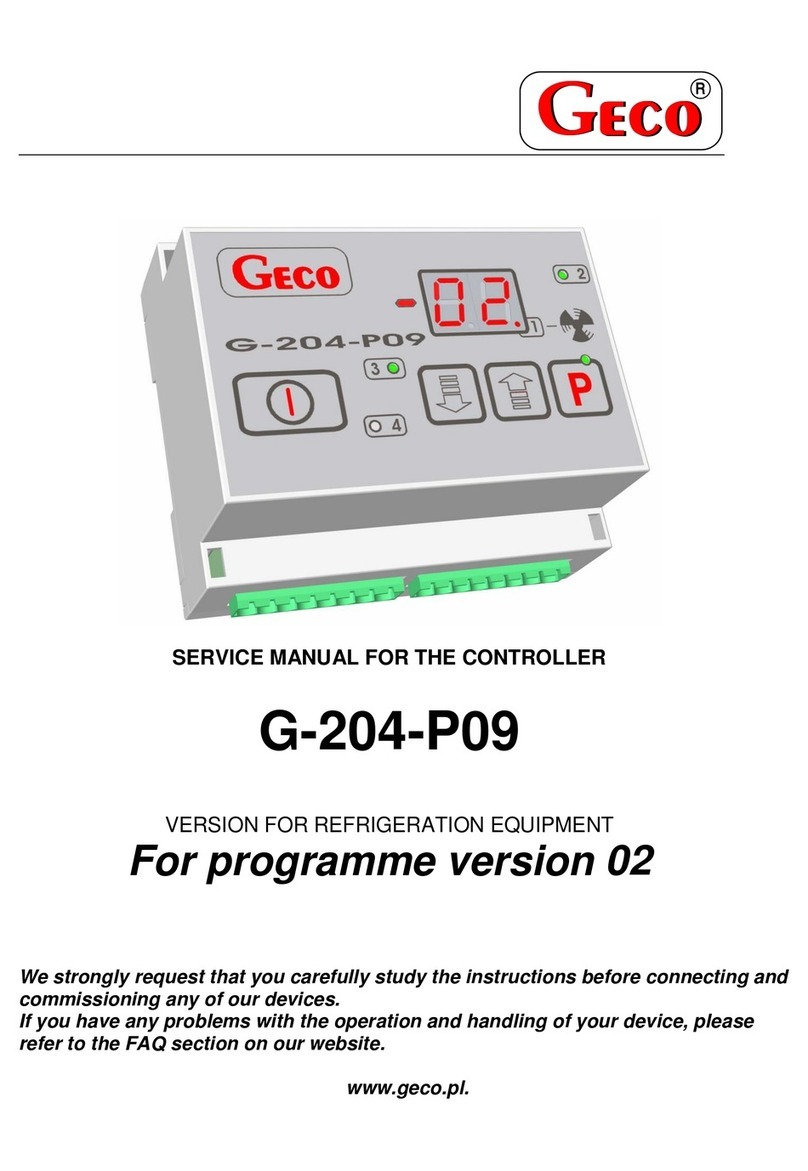

page 6 SERVICE MANUAL FOR MANUFACTURERS ICB TYPE G-204-P00K

PPUH “GECO” - G-204-P00K program version 01 PRINTOUT DATE 05-03-09

VI. PRINCIPLE OF OPERATION

A - General Information

1. As soon as the device is plugged in, a 3-second long start procedure will be executed. During that

procedure, the display will show two dots for one second, the controller program version for the next

second, and then two dots again. During that period no controlled device will be turned on.

2. As soon as the start procedure is complete, two horizontal dashes will light from point 1 on central

display segments. The dashes signal “live” condition – if the unit has not been previously on !!!.

Press push-button to activate the device. The display will show temperature value from the

room probe.

3. After pressing and holding push-button for 0.5 second, the display will start to blink and show

the evaporator temperature, and after another 5 seconds the G-204 will automatically return to the

room temperature readout. Attention!!! This function works also during defrosting, when the

display shows “dF”. It is also possible to see temperature from room probe by pressing for 0.5

second, the display will start to show room temperature (no blinking), and after another 5 seconds

the G-204 will automatically return to displaying “dF”.

4. Lighting small red diode (dot) in right bottom corner of the temperature display indicates

compressor activated. This allows for easier check of possible system defects.

5. If the compressor should be activated, and this does not happen because of activation of any

safeguards (see par. 6, 7, 10 and 11), the dot signalling compressor operation will keep blinking. As

soon as preset time from safeguards passes, the dot will start to light permanently and the

compressor will be activated.

6. Delay in compressor activation after reaching its activation temperature (temperature preset by user

minus lower hysteresis value) is 30 seconds. If the temperature drops during that period, the

condition of exceeded 30 seconds will be rechecked. This is expected to protect the compressor

from unnecessary activation due to e.g. putting products in, draughts, etc.

7. Each time after preset temperature is reached (temperature preset by user plus upper hysteresis

value), and after each power failure or voltage drop below 175V, the G-204 will make it impossible

to reactivate the compressor for time period specified by parameter ‘c2’. However, if ‘c2’=0min,

after current decay the safeguard will last for 60 seconds.

8. When the device is activated with push-button , there will be a 5-second delay in compressor

activation. However, user must remember that this cancels the power failure safeguard from par. 7 -

this also applies to time specified by parameter ‘c2’ after having switched the compressor off. This

allows for faster compressor operation check.

9. The controller has been equipped with alarms indicating probe damage. The controller will react in

different ways, depending on which probe has been damaged.

•Room temperature probe damage will result in symbol A1 being displayed. The controller will

turn on the compressor in time cycle (so-called clock control), according to time values specified

in parameters ‘c8’ and ‘c9’. Defrosting will function normally.

•Evaporator probe damage will result in alarm A2 being displayed. Manual and automatic

defrosting function will be blocked !!! The only method allowing to defrost the device is to

turn it off using push-button and to wait until ice melts naturally.

•In case if two probes fail simultaneously, only alarm A1 will be displayed. As soon as room

probe is repaired, alarm A2 will light.