Non-repetitive overcurrent t=20 ms: 600A

I2t for blowout: ≤1010A2s

dV/dt critical with output deactivated:

1000V/µs

GT 50 (SCR version)

Nominal currents of the device with

opportune heatsink in continuous work:

50A

Non-repetitive overcurrent t=20 ms: 1150A

I2t for blowout: ≤6600A2s

dV/dt critical with output deactivated:

1000V/µs

GT 60 (SCR version)

Nominal currents of the device with

opportune heatsink in continuous work:

60A

Non-repetitive overcurrent t=20 ms: 1150A

I2t for blowout: ≤6600A2s

dV/dt critical with output deactivated:

1000V/µs

GT 75 (SCR version)

Nominal currents of the device with

opportune heatsink in continuous work:

75A

Non-repetitive overcurrent t=20 ms: 1300A

I2t for blowout: ≤8000A2s

dV/dt critical with output deactivated:

1000V/µs

GT 90 (SCR version)

Nominal currents of the device with

opportune heatsink in continuous work:

90A

Non-repetitive overcurrent t=20 ms: 1500A

I2t for blowout: ≤11200A2s

dV/dt critical with output deactivated:

1000V/µs

GT 120 (SCR version)

Nominal currents of the device with

opportune heatsink in continuous work:

120A (complete with fan and standard

thermostat).

Non-repetitive overcurrent t=20 ms: 1500A

I2t for blowout: ≤11200A2s

dV/dt critical with output deactivated:

1000V/µs

Isolation

Rated isolation voltage input/output:

4000Vac

Power supply:

24Vac ±10%, 50/60 Hz

Absorption: 1.5VA

Max. isolation voltage: 300Vdc

Options:

Interrupted HB load alarm.

Controls the load by measuring current

on a shunt inside the device.

The alarm limit is set with a multirev

monorev trimmer.

The alarm output is obtained by means of

a solid state relay.

The contact is normally open (max. 30V,

150mA, conduction resistance 15Ω).

Thermal features

GT 25

Junction temperature: ≤125°C

Rth junction/case: ≤1.25 K/W

Rth junction/ambient: ≤12 K/W

GT 40

Junction temperature: ≤125°C

Rth junction/case: ≤0.65 K/W

Rth junction/ambient: ≤12 K/W

GT 50

Junction temperature: ≤125°C

Rth junction/case: ≤0.35 K/W

Rth junction/ambient: ≤12 K/W

GT 60

Junction temperature: ≤125°C

Rth junction/case: ≤0.35 K/W

Rth junction/ambient: ≤12 K/W

GT 75

Junction temperature: ≤125°C

Rth junction/case: ≤0.3 K/W

Rth junction/ambient: ≤12 K/W

GT 90

Junction temperature: ≤125°C

Rth junction/case: ≤0.3 K/W

Rth junction/ambient: ≤12 K/W

GT 120

Junction temperature: ≤125°C

Rth junction/case: ≤0.25 K/W

Rth junction/ambient: ≤12 K/W

Solid State Relay Dissipated Power

Calculation

Singol-phase static relay

Pds = 1.4 * IRMS [W]

IRMS = singol phase load current

Heatsink thermal resistance

Calculation

Rth = (90°C - T.amb. max) / Pd

where Pd = dissipated power

T.amb.max = max air temperature inside

the electrical cabinet.

Use a heatsink with thermal resistance

inferior to the calculated one (Rth).

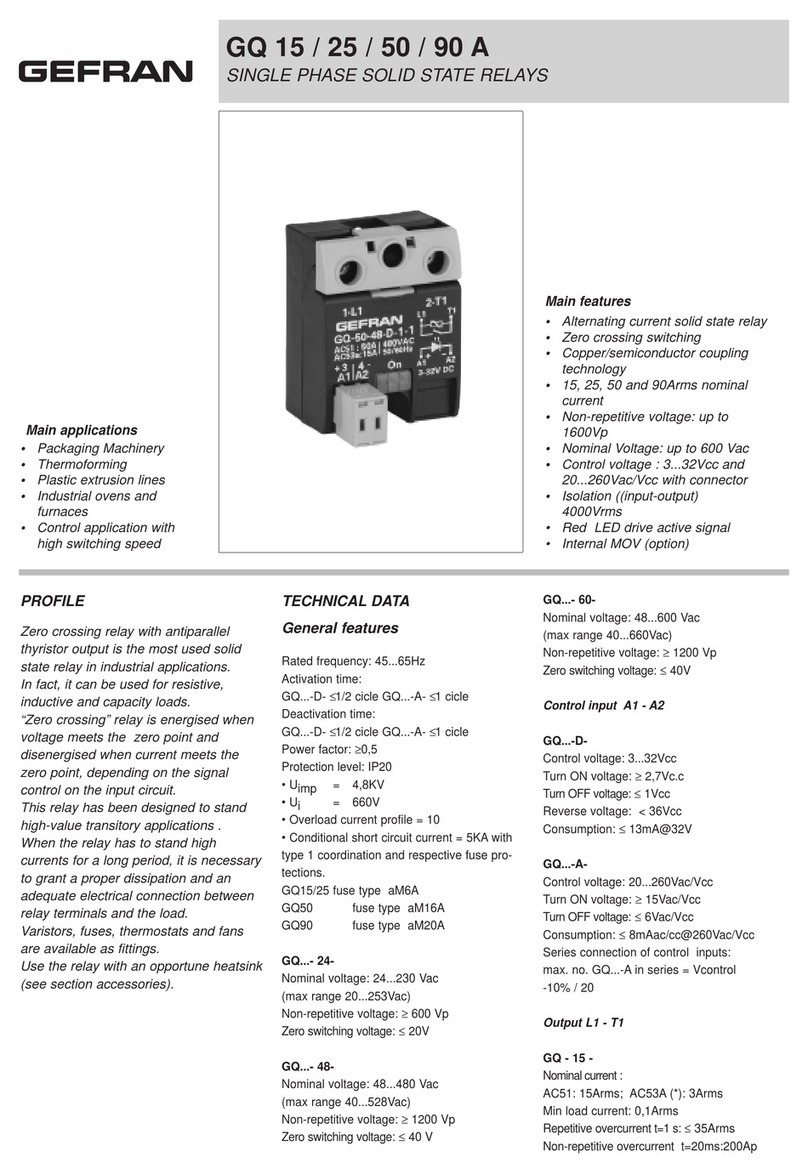

Ambient conditions

• Working temperature: 0 to 80°C.

• Max. relative humidity: 50% at 40°C

• Max. installation altitude:

2000m asl

• Pollution level: 3

• Storage temperature: -20..85°C

Installation notes

- The heat sink must be grounded.

- The device must be protected by an

appropriate high-speed fuse (accessory).

- Applications with solid state power units

must also include an automatic safety

switch to cut out the load power line.

- Protect the solid state relay by using an

appropriate heat sink (accessory).

The heat sink must be sized according to

room temperature and load current (see

the technical documentation).

- Procedure for mounting on heat sink:

The module-heat sink contact surface

must have a maximum planarity error of

0.05mm. and maximum roughness of

0.02mm. The fastening holes on the heat

sink must be threaded and countersunk.

Attention: spread 1 gram of

thermoconductive silicone (we

recommend DOW CORNING 340

HeatSink) on the dissipative metal

surface of the module.

The surfaces must be clean and there

must be no impurities in the

thermoconductive paste.

Alternately tighten the two fastening

screws until reaching a torque of 0.60

Nm for the M4 screws and 0.75 Nm for

the M5 screws.

Wait 30 minutes for any excess paste to

drain.

Alternately tighten the two fastening

screws until reaching a torque of 1.2 Nm

for the M4 screws and 1.5 Nm for the M5

screws.

We advise you to randomly check for

proper installation by dismantling the

module to make sure there are no air

bubbles under the copper plate.

Limits of use

• dissipation of thermal power of device

with restrictions on temperature of

installation site.

• requires exchange with outside air

or an air conditioner to transfer

dissipated power outside the panel.

• installation restrictions (distances

between devices to guarantee dissipation

by natural convection).

• max. voltage limits and derivative

of transients in line, for which the

solid state unit has internal protection

devices (depending on model).

• presence of dispersion current

< 3mA for SCR version GS

< 4mA for TRIAC version GS

(max. value with rated voltage

and junction temperature of 125°C).