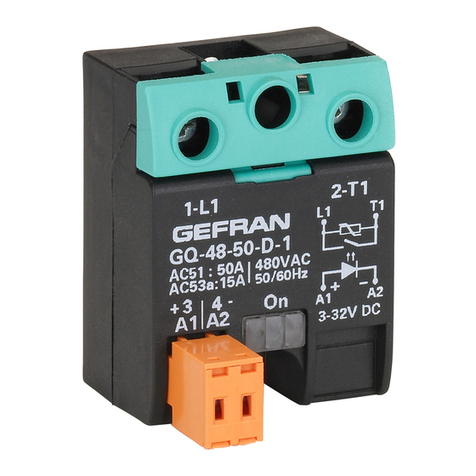

FACEPLATE DESCRIPTION

L1 : Phase 1 input

L2 : Phase 2 input

L3 : Phase 3 input

T1 : Phase 1 output

T2 : Phase 2 output

T3 : Phase 3 output

A1 : Control signal (+)

A2 : Control signal (-)

B1 : Alarm output (+) option

B2: Alarm output (-) option

Led1: Red led signal indicator

Led2: Yellow led (alarm overtemperature

junction)

Insulation

Nominal insulation voltage

input/output:

2.5KV ac for models with Ue=400Vac

4KV ac for models with Ue=480Vac,

Ue=600Vac

Nominal impulse withstand voltage

(Uimp): 2500Vac

Ambient conditions

• Working temperature:

-20°C...80°C

• Max. relative humidity: 50% to 40°C

• Max. installation altitude: 1000 slm

• Pollution level : 3

• Storage temperature: -20...85°C

• Class: A (industrial device)

• Suitable for use in pollution degree 2

environmental

Thermal protection

Junction temperature is constantly moni-

tored inside the device. If the maximum

temperature limit is exceeded (T=110°C),

current to the load is interrupted and the

yellow signal LED lights up.

Options

An optional thermal protection alarm out-

put is available. In this case, the alarm is

signaled with an output generated by a

solid state relay (max. 32 VAD/DC,

150mA, resistance ≤15Ωin alarm

state).

Power supply

Fan supply

(only for models GTZ 40/55A):

230Vac 14W (VEN90)

115Vac 14W (VEN91)

Installation notes

Use the high speed fuses specified in the

catalog according to the connection

example provided.

Applications with solid state power units

must also include an automatic safety

switch to cut out the load power line.

For maximum reliability, the device

MUST be installed correctly in the panel

in order to have adequate heat exchange

between the heatsink and the

surrounding air under conditions of

natural convection.

Mount it vertically (max. 10 inclination

from the vertical axis)

• Vertical distance between a heatsink

and the panel wall >100mm

• Horizontal distance between a heatsink

and the panel wall: 20mm at least

• Vertical distance between two heatsink:

300mm at least.

• Horizontal distance between two heat-

sink: 20mm. at least

Check that cable raceways do not reduce

these distances; should it happen, mount

the GTZ overhanging from the panel, so

that the air can flow vertically on the

heatsink without obstables.

• Maximum surrounding air temperature

40°C (for UL).

• Open type equipment

Limits of use

• dissipation of thermal power of device

with restrictions on temperature of instal-

lation site.

• requires exchange with outside air

or an air conditioner to transfer

dissipated power outside the panel.

• installation requirements (distances

between devices to guarantee dissipation

under conditions of natural convection)

• max. voltage limits and derivative

of transients in line, for which the

solid state unit has internal protection

devices.

• presence of dispersion current

< 10mA (max. value with rated voltage

and junction temperature of 125°C).