DIMENSIONS

Dimensions in mm, (inc) (*) See installation notes

*Apply thermoconductive

paste Raise the guard to access the

fastening hole or the terminals

Repetitive overcurrent t=1 s: ≤35Arms

Non-repetitive overcurrent t=20ms:200Ap

Current drop at nominal voltage and

frequencies: ≤8mArms

I2t for fusing t=1-10ms: ≤200A2s

Critical dl/dt: ≥100A/µs

Voltage drop at nominal current: ≤1,45Vrms

Critical dV/dt off-state: ≥1000V/µs

Ith = 15A

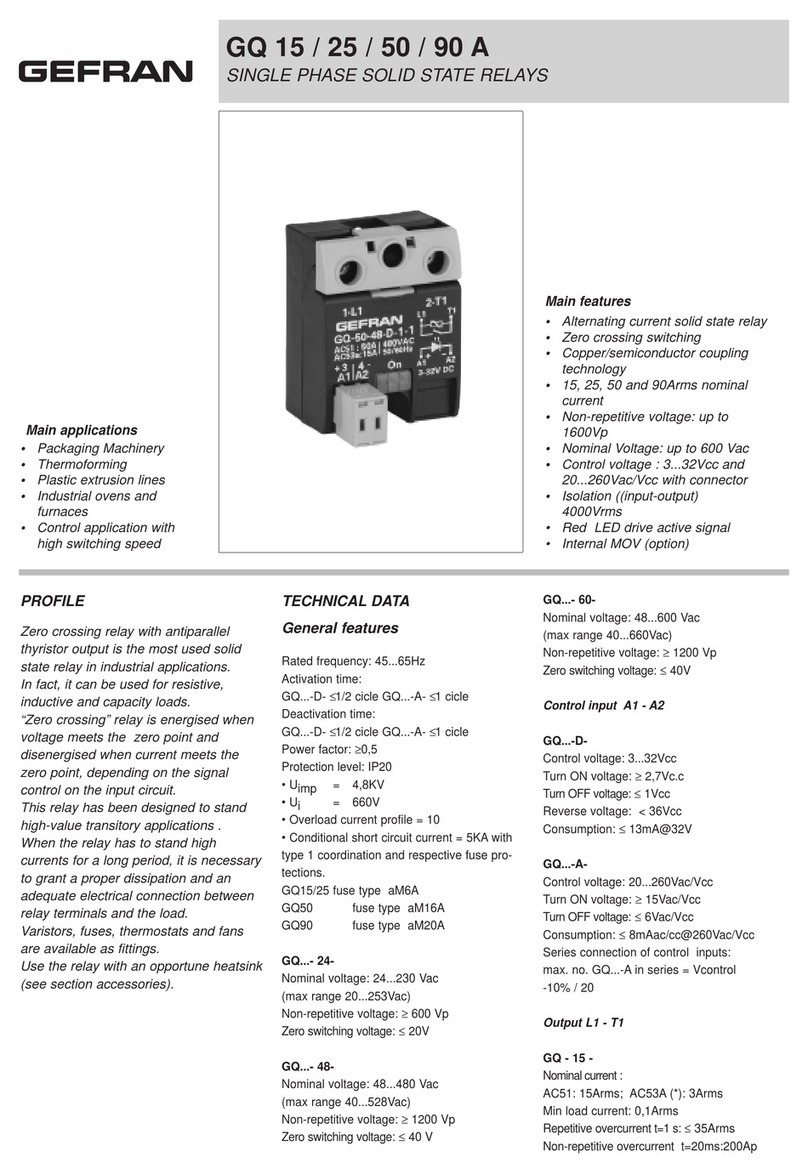

GQ - 25 -

Nominal current :

AC51: 25Arms; AC53: 5Arms

Min load current: 0,3Arms

Repetitive overcurrent t=1 s: ≤60Arms

Non-repetitive overcurrent t=20ms: 300Ap

Current drop at nominal voltage and

frequencies: ≤8 mArms

I2t for fusing t=1-10ms: ≤450A2s

Critical dl/dt: ≥100A/µs

Voltage drop at nominal current: ≤1,45Vrms

Critical dV/dt off-state:≥1000V/µs

Ith = 25A

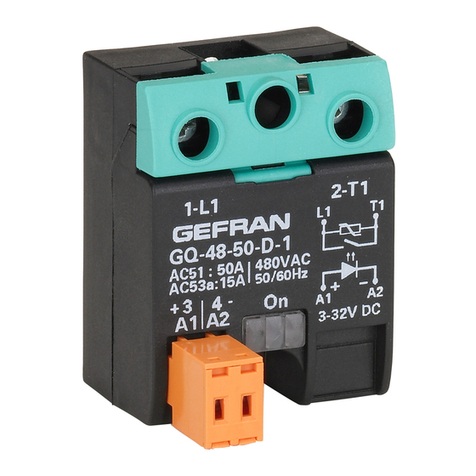

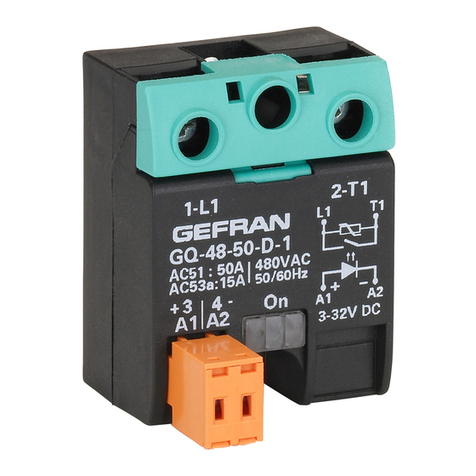

GQ - 50 -

Nominal current :

AC51: 50Arms;AC53: 15Arms

Min load current: 0,3Arms

Repetitive overcurrent t=1 s: ≤125Arms

Non-repetitive overcurrent t=20ms: 600Ap

Current drop at nominal voltage and

frequencies: ≤8mArms

I2t for fusing t=1-10ms: ≤1800A2s

Critical dl/dt: ≥100A/µs

Voltage drop at nominal current: ≤1,35Vrms

Critical dV/dt off-state: ≥1000V/µs

Ith = 50A

GQ - 90 -

Nominal current

AC51: 90Arms;AC53: 20Arms

Min load current: 0,5Arms

Repetitive overcurrent t=1 s: ≤150Arms

Non-repetitive overcurrent t=20ms: 1500Ap

Current drop at nominal voltage and

frequencies: ≤10mArms

I2t for fusing t=1-10ms: ≤11200A2s

Critical dl/dt: ≥100A/µs

Voltage drop at nominal current:≤1,35Vrms

Critical dV/dt off-state: ≥1000V/µs

Ith = 90A

(*) Only versions:GQ-XX-24-X-1

GQ-XX-48-X-1

Insulation

Nominal insulation voltage

Input/output:: ≥4000 Vac

Nominal insulation voltage

Output/case: ≥2500 Vac

Insulation resistance

Input/output: ≥1010Ω

Insulation resistance

Output/case: ≥1010Ω

Insulation capacity Input/Output: ≤8pF

Insulation capacity Output/case: ≤100pF

Ambient conditions

• Ambient temeparure: -25...+80°C

• Storage Temperature: -55...+100°C

• Maximum relative humidity: 50% a 40°C

• Maximum installation height: 2000 slm

• Pollution level: 3

Thermal features

GQ - 15 - / GQ - 25 -

Junction Temperature: ≤125°C

Rth junction/case: ≤1,25 K/W

Rth junction/ambient: ≤12 K/W

GQ - 50 -

Junction Temperature: ≤125°C

Rth junction/case: ≤0,65 K/W

Rth junction/ambient: ≤12 K/W

GQ - 90 -

Junction Temperature: ≤125°C

Rth junction/case: ≤0,3 K/W

Rth junction/ambient: ≤12 K/W

Solid State Relay Dissipated Power

Calculation

Single phase state relay

PdGQ .. 15/25 = 1,45 . Irms [W]

PdGQ .. 50/90 = 1,35 . Irms [W]

IRMS = single-phase load current

Heatsink Thermal Resistance

Calculation

Rth = (90°C - T.amb. max) / Pd

where Pd = dissipated power

Max. amb. T = max air temperature

inside the electrical cabinet.

Use a heatsink with thermal resistance

inferior to the calculated one (Rth).

Installation notes

The device must be protected by a high

speed fuse (accessory).

Applications with power solid state relays

must also have a switch to isolate the

power line.

Protect the solid state relay against over-

heating by using a heatsink (accessory).

The heatsink must be sized according to

room temperature and load current (see

technical data).

Heatsink installation procedure: