C. Gerhardt GmbH & Co. KG

2

VAPODEST20

Contents

Safety .......................................................................................... 3

Application as directed ................................................................ 3

Safety instructions ....................................................................... 3

1 Technical description........................................................ 4

Warranty conditions..................................................................... 4

Technical data ............................................................................. 4

Operating conditions................................................................... 5

2 Description of the system................................................. 6

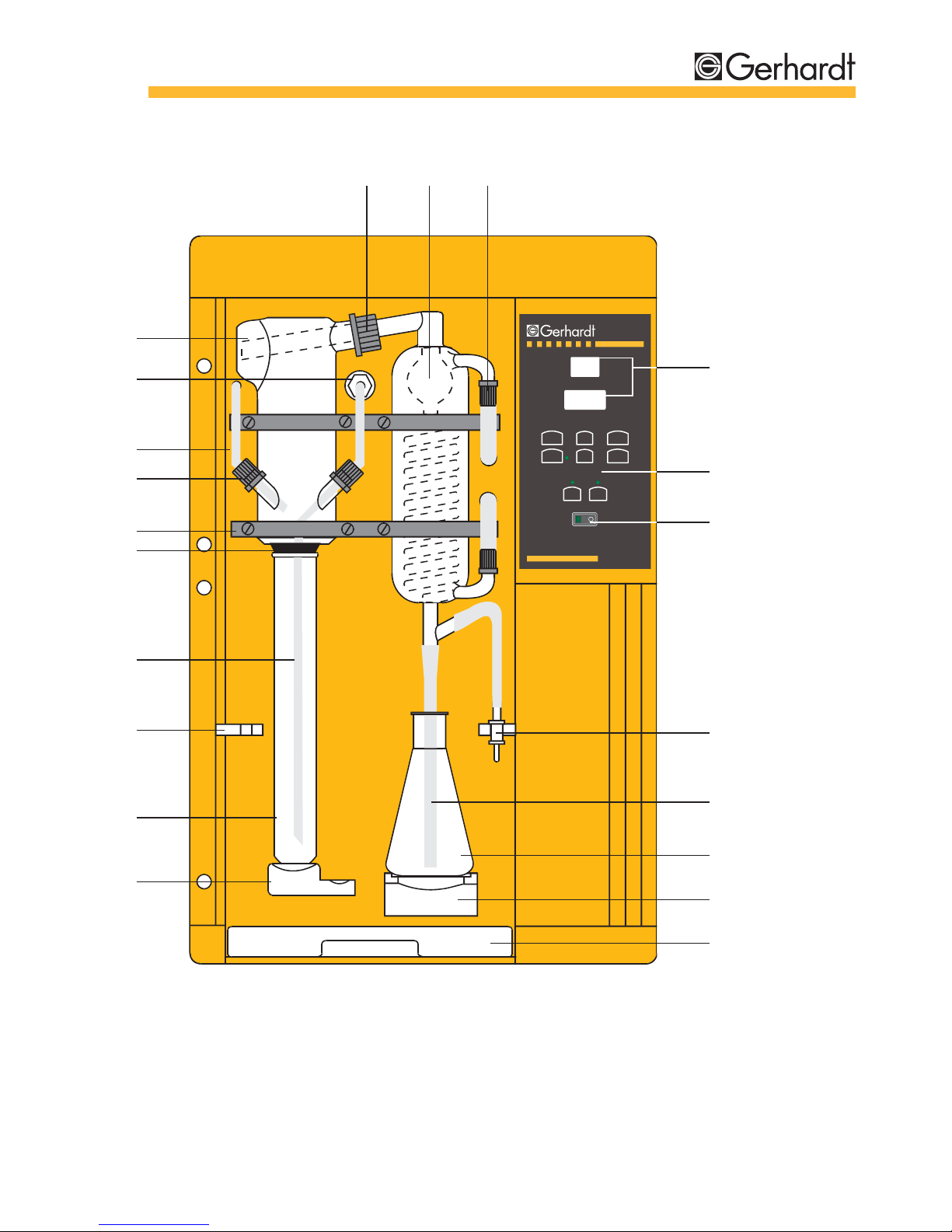

Front view..................................................................................... 6

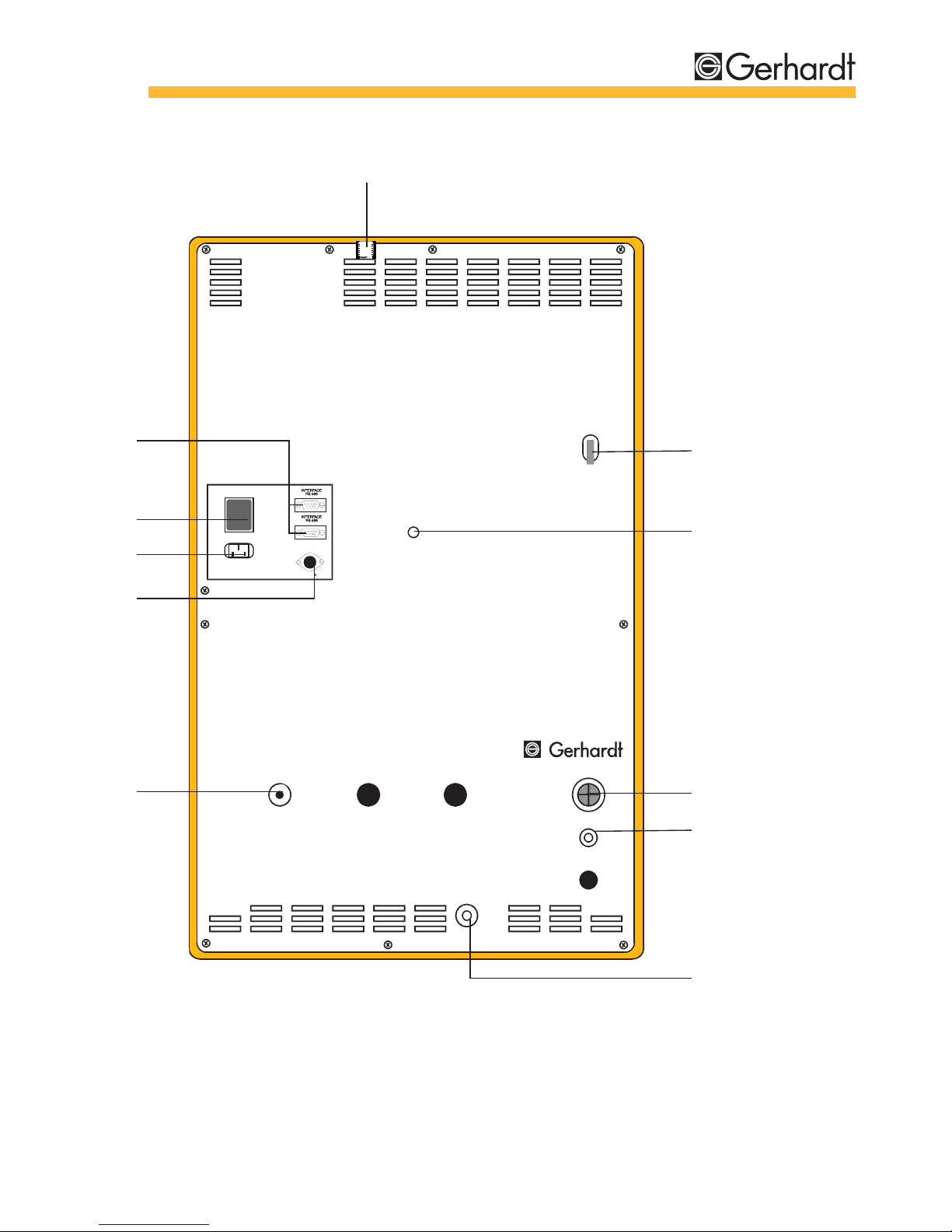

Rear view ..................................................................................... 8

3 Delivery............................................................................. 10

Check for transport damage ..................................................... 10

Parts list..................................................................................... 10

4 Assembly and installation................................................11

Setup ..........................................................................................11

Setting into operation ................................................................ 12

5 Programming the system............................................... 14

Keyboard ................................................................................... 14

Programming the Vapodest 20 ................................................. 17

On-line mode............................................................................. 19

6 Operation ......................................................................... 21

Safety instructions ..................................................................... 21

Priming the system ................................................................... 21

Test run ...................................................................................... 22

Distilling a sample .................................................................... 23

7 Error messages .............................................................. 24

8 Maintenance .................................................................... 26

Tubing diagram ......................................................................... 26

Spare parts and accessories.................................................... 28

Service and cleaning ................................................................. 30

Trouble shooting ....................................................................... 30

Disposal .................................................................................... 31