C. Gerhardt GmbH & Co. KG

2

VAPODEST 30

Contents

Safety ........................................................................................... 3

Application as directed ..................................................................3

Safety instructions ........................................................................3

1 Technical description ........................................................ 4

Warranty conditions ...................................................................... 4

Technical data .............................................................................. 4

Operating conditions ..................................................................... 5

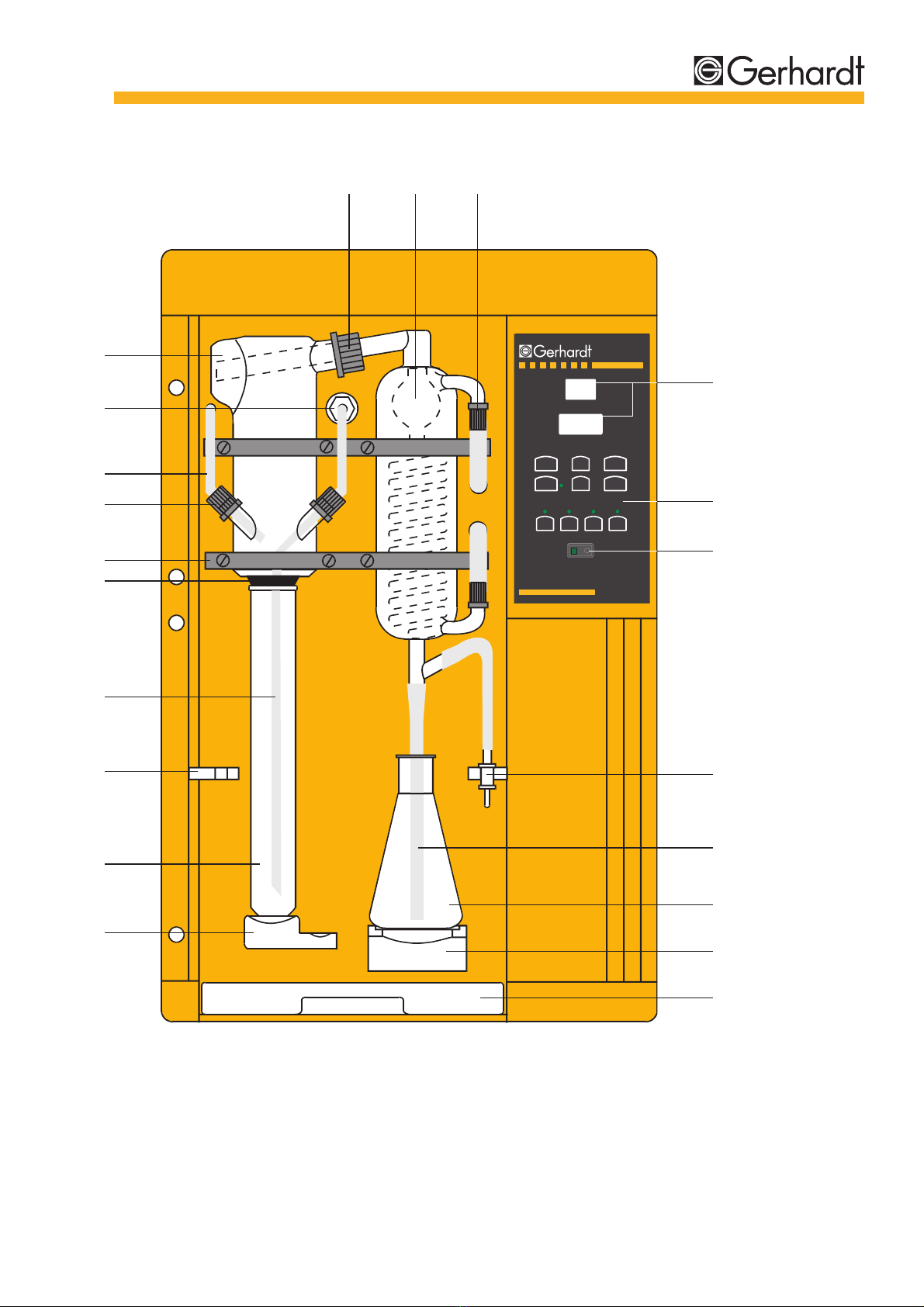

2 Description of the system ................................................. 6

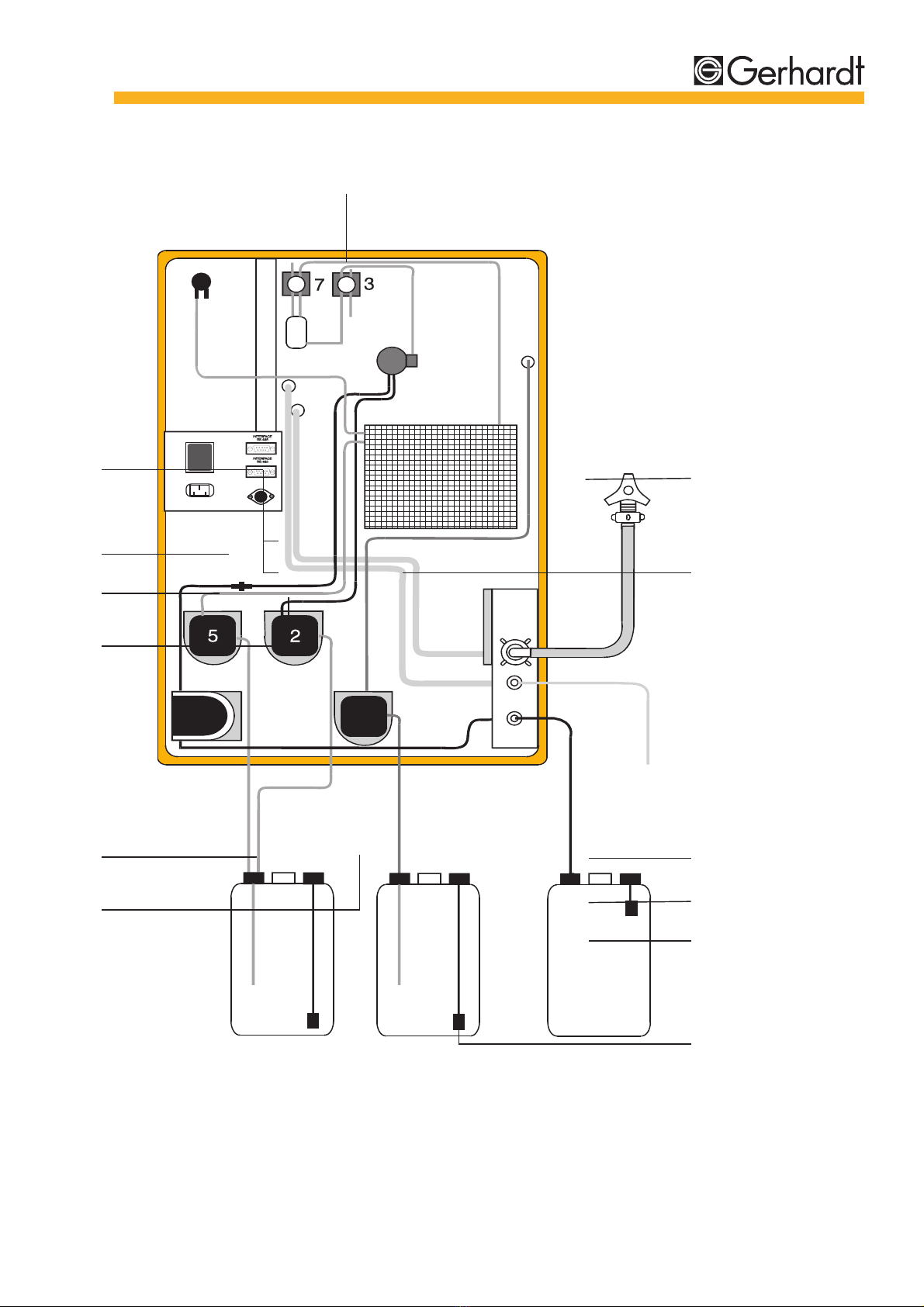

Front view ..................................................................................... 6

Rear view ...................................................................................... 8

3 Delivery .............................................................................10

Check for transport damage .......................................................10

Parts list ......................................................................................10

4 Assembly and installation .............................................. 11

Setup ...........................................................................................11

Setting into operation ..................................................................12

5 Programming the system ................................................ 14

Keyboard .....................................................................................14

Programming the Vapodest 30 ...................................................17

On-line mode ..............................................................................19

6 Operation ..........................................................................21

Safety instructions ......................................................................21

Priming the system .....................................................................21

Test run .......................................................................................22

Distilling a sample .......................................................................23

7 Error messages ................................................................24

8 Maintenance .....................................................................26

Tubing diagram ........................................................................... 26

Spare parts and accessories ......................................................28

Service and cleaning ..................................................................30

Trouble shooting .........................................................................30